Full flexible transparent touch control system

A touch-control system, fully flexible technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of repeated failure, small curvature radius bending, etc., and achieve stable device structure, The effect of broadening the scope of application and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

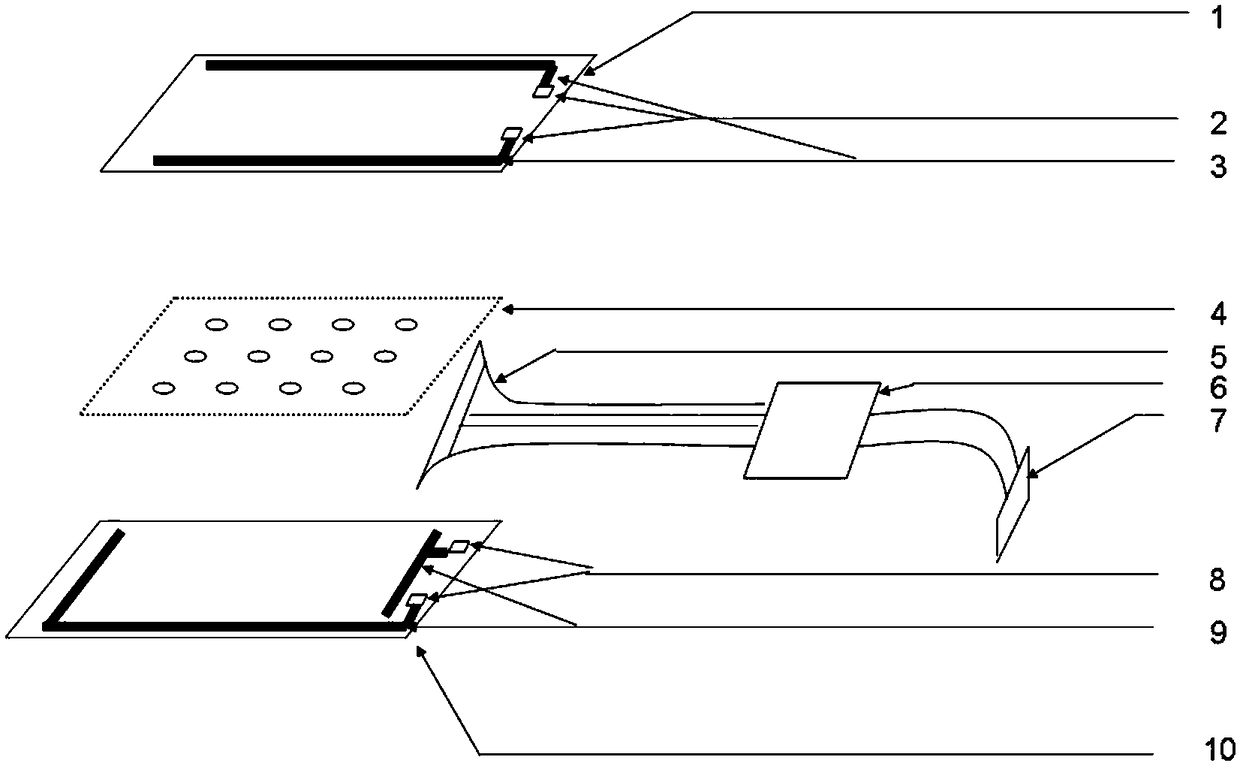

[0031] Embodiment 1: A fully flexible transparent touch system, including: two flexible transparent conductive layers, an insulating and isolated dot matrix layer, and surrounding conductive electrodes.

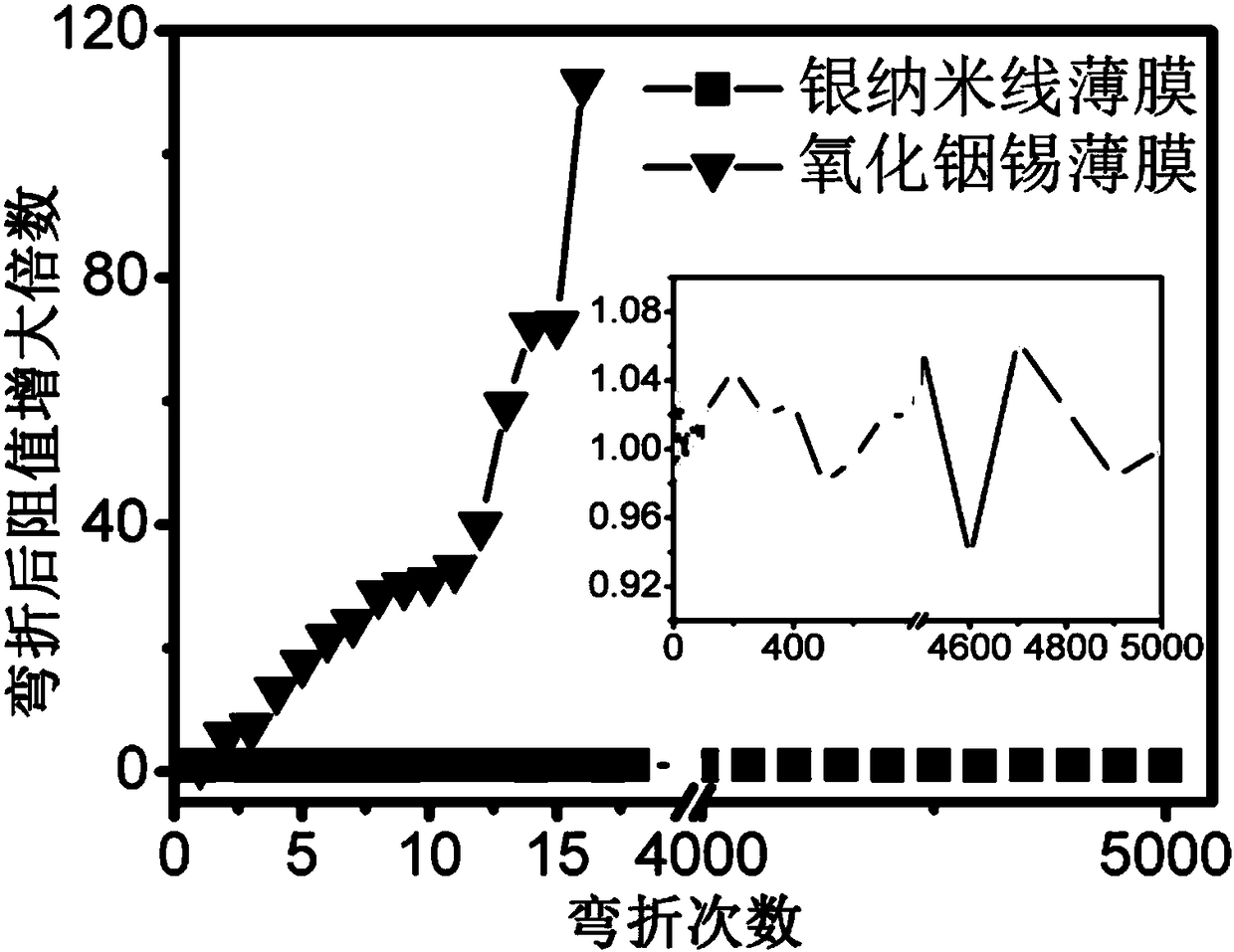

[0032]The flexible transparent conductive layer is composed of a flexible substrate and a transparent conductive film coated on the flexible substrate by randomly overlapping metal nanowires to form a grid. In this embodiment, polyethylene terephthalate with a thickness of 100 μm is selected as the flexible substrate, and the visible light transmittance is greater than 92%. The silver nanowire thin film is coated on the rectangular flexible substrate with an automatic scraper coating device, the sheet resistance is 800Ω, the diameter of the silver nanowire is 20nm, and the length is 20μm. The size of the two flexible transparent conductive layers is the same, and they are respectively on the uppermost layer and the lowermost layer of the touch system. The silver nanowire film...

Embodiment 2

[0037] Embodiment 2: A fully flexible transparent touch system, such as figure 1 As shown, it includes: two layers of flexible transparent conductive layers, an insulating and isolated lattice layer, and surrounding conductive electrodes.

[0038] The flexible transparent conductive layer is composed of a flexible substrate and a transparent conductive film coated on the flexible substrate by randomly overlapping metal nanowires to form a grid. In this embodiment, polyimide with a thickness of 50 μm is selected as the flexible substrate, and the visible light transmittance is greater than 85%. The silver nanowire thin film is coated on the rectangular flexible substrate with an automatic scraper coating device, the sheet resistance is 300Ω, the diameter of the silver nanowire is 50nm, and the length is 50μm. The size of the two flexible transparent conductive layers is the same, and they are respectively on the uppermost layer and the lowermost layer of the touch system. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com