Insulation cotton containing aerogel and production process thereof

A production process and airgel technology, applied in the field of fabrics, can solve problems such as high risk, ash phenomenon, and user health problems, and achieve the effects of good lightness, good air permeability, and high-efficiency heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

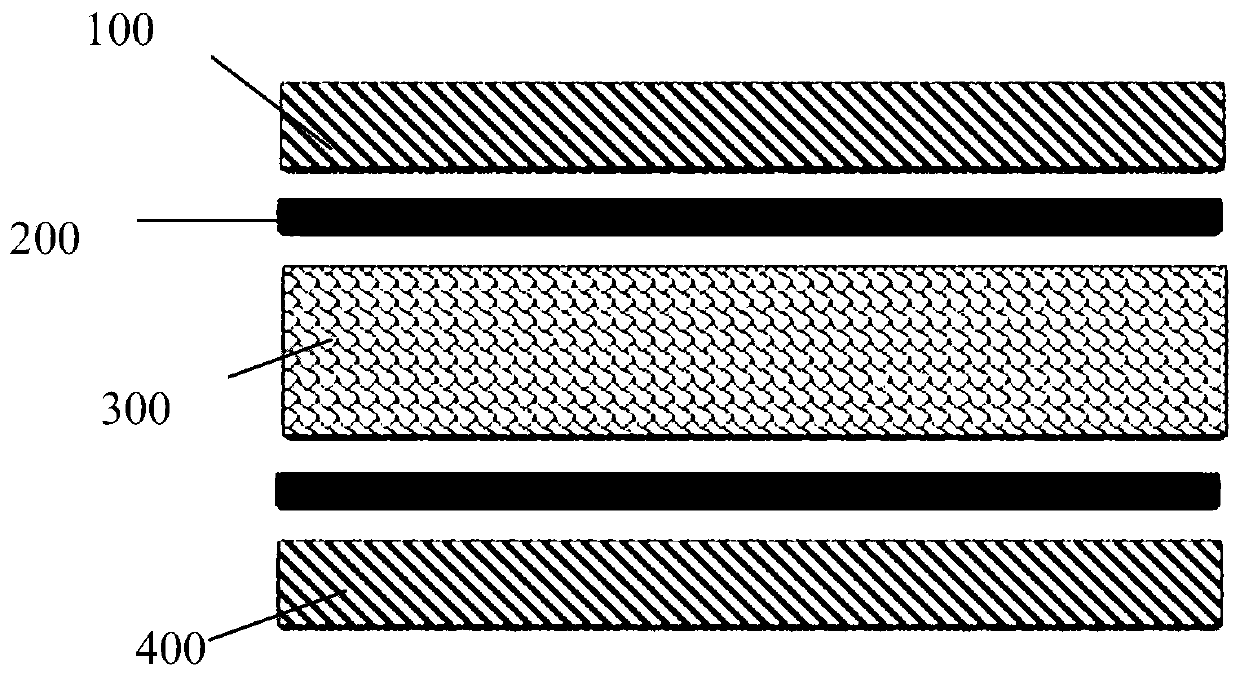

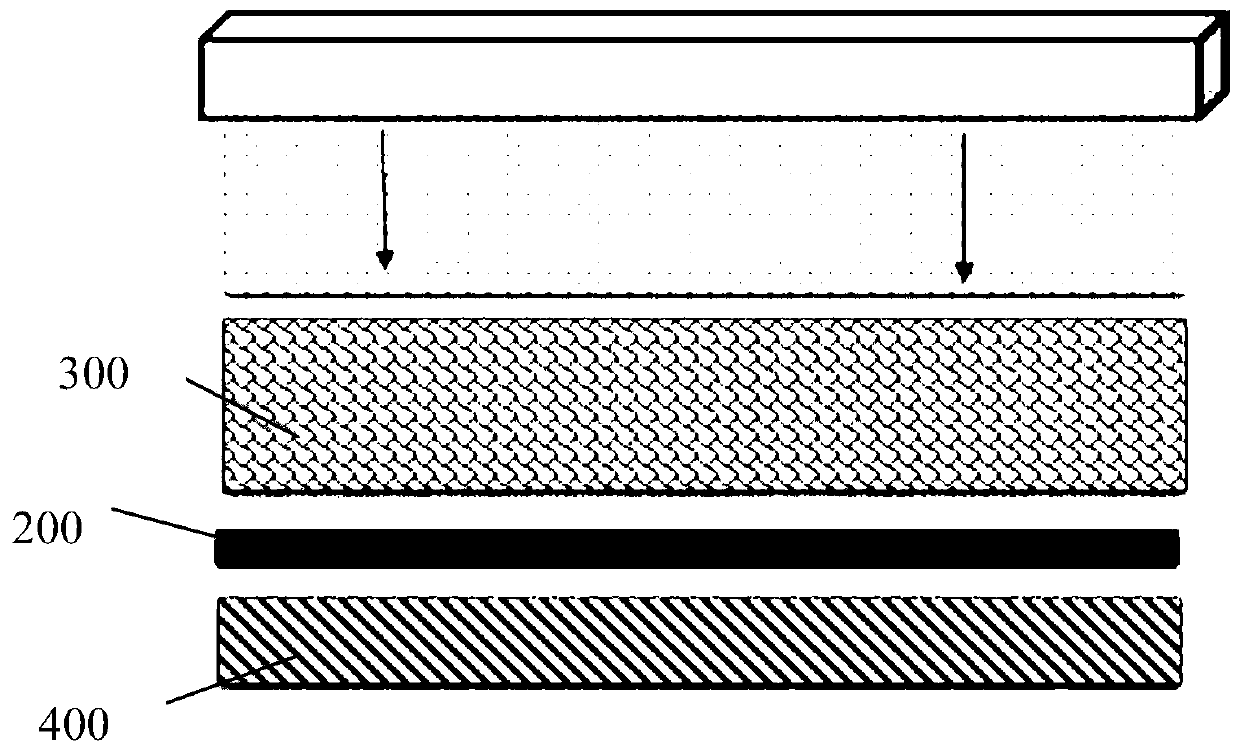

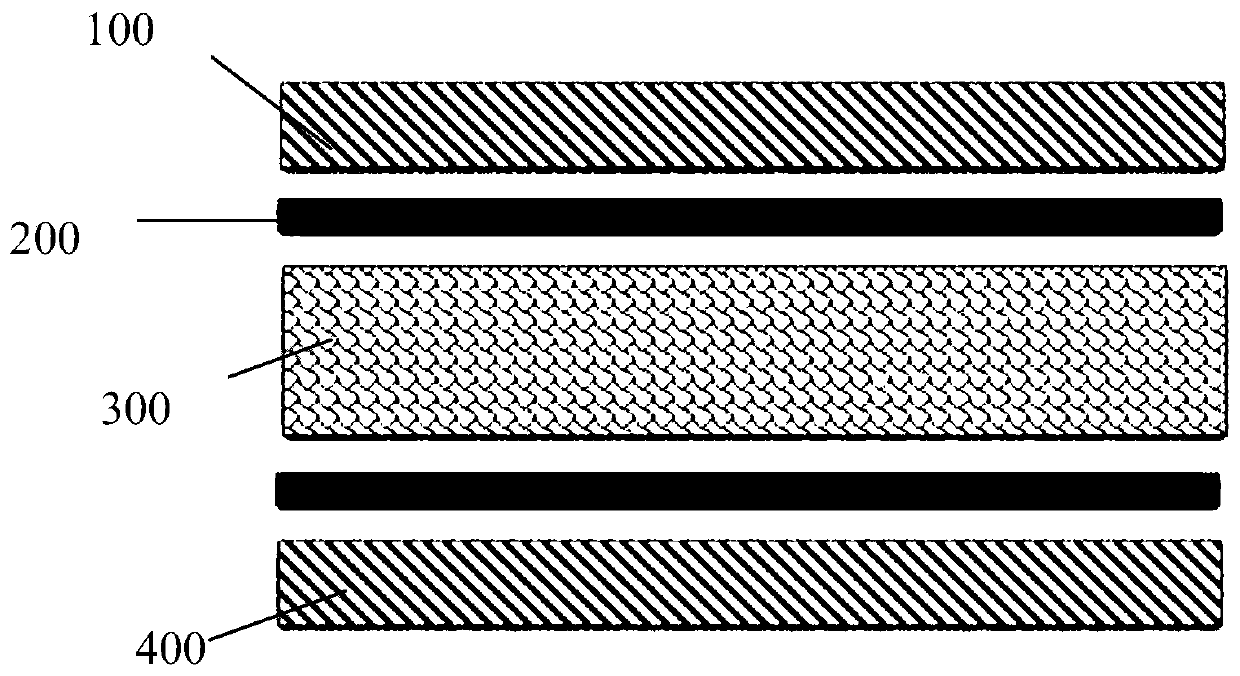

[0033] figure 1 It is a structural schematic diagram of the present invention. figure 2 It is a schematic diagram of the implementation of step 3.

[0034] Such as figure 1 and figure 2 As shown, the thermal insulation cotton containing airgel includes: bottom polyester cotton layer 100, TPU film layer 200, material layer 300 and surface layer polyester cotton layer 400, material layer 300 is wrapped in TPU film layer 200, TPU film layer 200 is set Between the bottom polyester cotton layer 100 and the surface layer polyester cotton layer 400;

[0035] Wherein, the material layer 300 includes: polyester cotton layer and 1-20% airgel, and the polyester cotton layer includes: 0-60% down, 20-99% polyester and 0-60% cupro.

[0036] The bottom polyester cotton layer 100 is made of polyester cotton, and the square gram weight range of the bottom polyester cotton layer 100 is 20 grams to 200 grams.

[0037] The surface polyester cotton layer 400 is made of polyester cotton, and...

Embodiment 2

[0057] In the present invention, the proportion of the polyester cotton layer is: 50% polyester + 48% cupro. The airgel of the material layer 300 is sprayed, and the proportion of the airgel is 2%. Down can not be added, and the present invention can still be produced. Without down, the thermal performance is reduced, but it is lighter and thinner, and at the same time, it can still heat itself through the copper ammonia wire.

Embodiment 3

[0059] In the present invention, the proportioning ratio of the polyester cotton layer is: polyester 98%. The airgel of the material layer 300 is sprayed, and the proportion of the airgel is 2%. Down and cupro can not be added, and the present invention can still be produced. Without down and cupro, the idea is the same as in Example 2. By reducing the cost, the effect of airgel can be played as much as possible, and it is also lighter and thinner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square gram weight | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com