High-strength injection molding material formula

A high-strength, formula-based technology, applied in the field of injection molding material formula, can solve problems such as color mixing and floating fibers, difficult demoulding, easy aging, etc., to achieve the effect of convenient molding and insulation, simple injection molding process, and not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1, a high-strength injection molding material formulation, which is composed of the following raw materials: Nylon 66 with the brand name 21SPC produced by Solutia Chemicals: 34KG, glass staple fibers produced by Jushi Company: 59KG, and maleic anhydride as a toughening agent POE grafting: 4kg, octadecyl propionate as an antioxidant: 1kg, PETS-AP as a flow agent: 1kg, plasticizer: 1kg.

Embodiment 2

[0010] Example 2, a high-strength injection molding material formula, which is composed of the following raw materials: Nylon 66 with the brand name of 21SPC produced by Solutia Chemicals: 32KG, nylon 6 material with the brand name of 3280 produced by Yueyang Chemical Industry: 2KG, produced by Jushi Company Glass staple fiber: 60KG, maleic anhydride POE grafting as a toughening agent: 3.5kg, n-octadecanyl propionate as an antioxidant: 0.8kg, PETS-AP as a flow agent: 0.8kg, Plasticizer: 0.9kg.

Embodiment 3

[0011] Example 3, a high-strength injection molding material formula, which is composed of the following raw materials: Nylon 66 with the brand name of 21SPC produced by Solutia Chemicals: 33KG, nylon 6 material with the brand name of 3280 produced by Yueyang Chemical Industry: 3.5KG, produced by Jushi Company Glass staple fiber: 61KG, maleic anhydride POE grafting as a toughening agent: 1kg, octadecyl propionate as an antioxidant: 0.5kg, PETS-AP as a flow agent: 0.5kg, Plasticizer: 0.5kg.

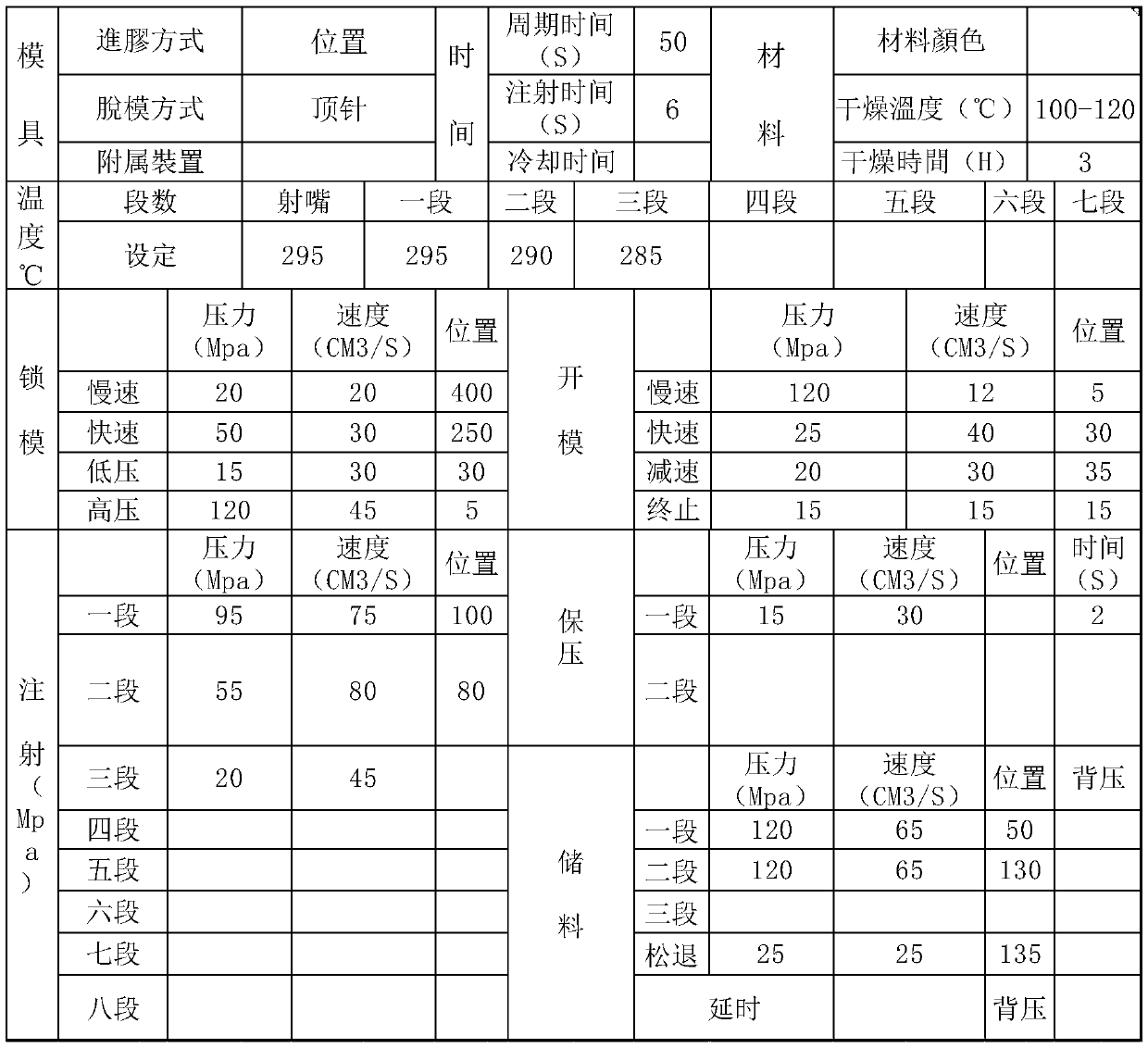

[0012] When using the formula of the present invention to manufacture the door hinge of a certain brand of drum-type washing machine, its injection molding process is shown in the table below:

[0013]

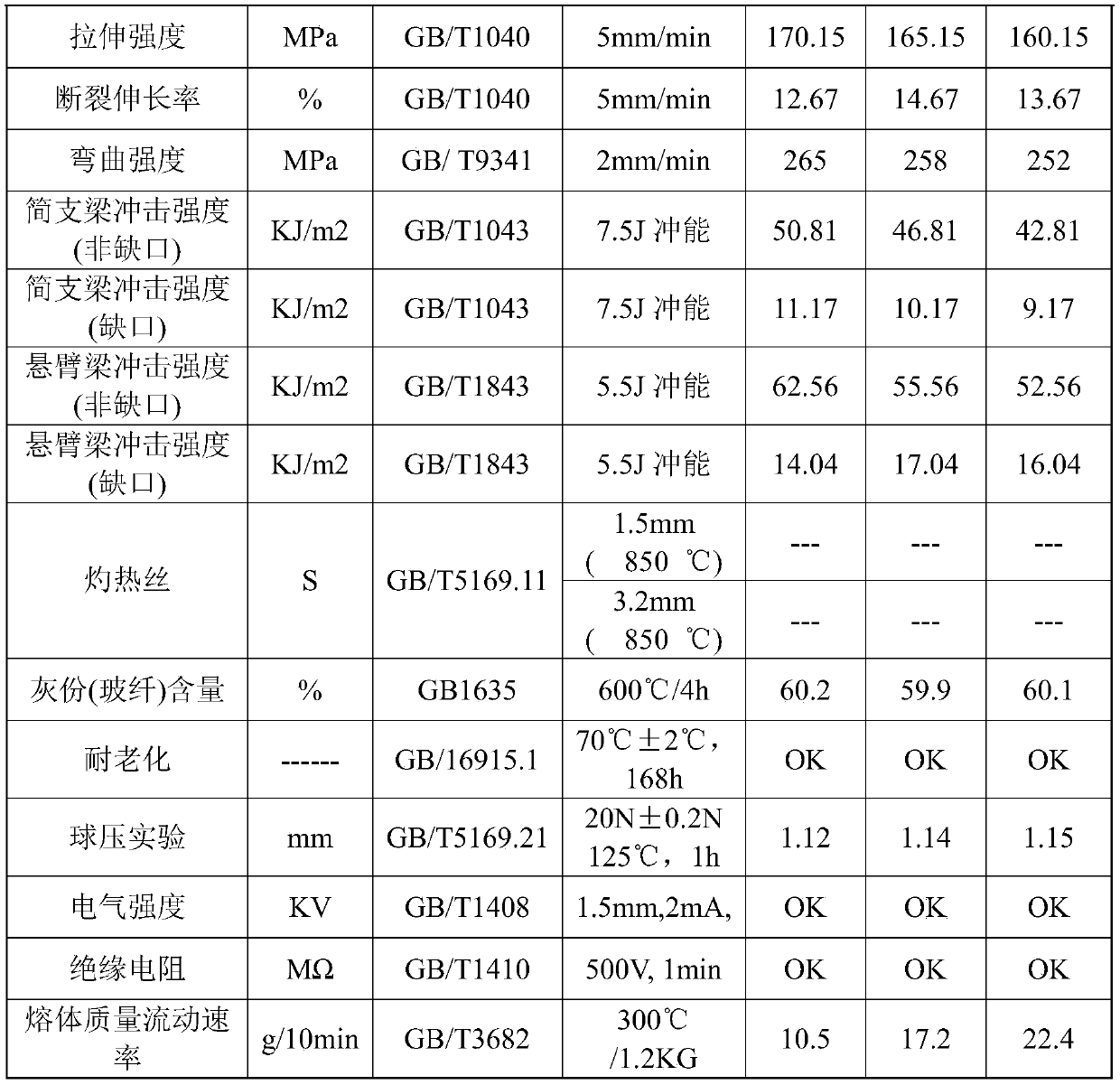

[0014] After testing the door hinges manufactured by using the formula of the present invention and the above-mentioned injection molding process, the performance results are compared as follows:

[0015]

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com