Induction heating device in steel pipe and heating method with induction heating device

An induction heating device and built-in heating technology are applied in the field of steel pipe heating to achieve the effects of convenient equipment installation, less oxidation and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

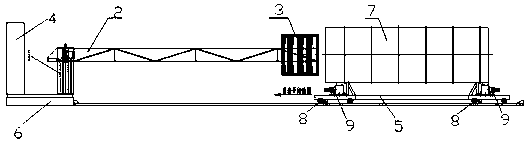

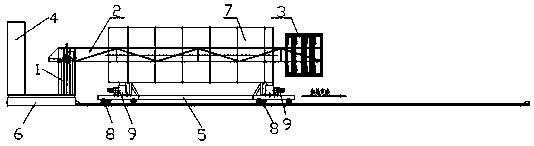

Method used

Image

Examples

Embodiment 1

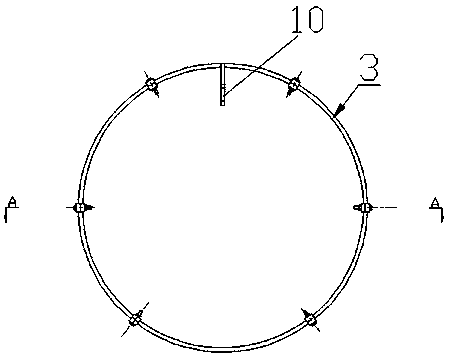

[0042] 1) Place the steel pipe with a diameter of 630mm on the transfer trolley to measure the center height of the steel pipe, then place the medium frequency induction coil on the cantilever, adjust the height of the cantilever to keep the coil and the steel pipe at the same center height and ensure the gap between the coil and the steel pipe Evenly, connect the coil and the intermediate frequency equipment with water cables, after the intermediate frequency equipment is powered on and watered;

[0043] 2) Start the intermediate frequency heating equipment. After the steel pipe is heated, the temperature is 200 ℃ ~ 220 ℃, the time is 25 minutes, the intermediate frequency voltage is 260V, and the DC current is 380A;

[0044] 3) Adjust the roller spacing of the transfer trolley to 450mm, the steel pipe speed to 20r / min, and the travel speed of the transfer trolley to 480mm / min;

[0045] 4) The tube transfer trolley moves forward evenly at the set speed, and starts to heat the...

Embodiment 2

[0047] 1) Place the steel pipe with a diameter of 1020mm on the pipe transfer trolley to measure the center height of the steel pipe, then place the intermediate frequency induction coil on the cantilever, adjust the height of the cantilever to keep the coil and the steel pipe at the same center height and ensure the gap between the coil and the steel pipe Evenly, connect the coil and the intermediate frequency equipment with water cables, after the intermediate frequency equipment is powered on and watered;

[0048] 2) Start the intermediate frequency heating equipment. After the steel pipe is heated, the heating temperature is 200 ℃ ~ 220 ℃, the time is 30 minutes, the intermediate frequency voltage is 370V, and the DC current is 500A;

[0049] 3) Adjust the roller spacing of the transfer trolley to 670mm, the roller speed to 12r / min, and the travel speed of the transfer trolley to 400mm / min;

[0050] 4) The tube transfer trolley moves forward evenly at the set speed, and st...

Embodiment 3

[0052] 1) Place the steel pipe with a diameter of 2020mm on the transfer trolley to measure the center height of the steel pipe, then place the medium frequency induction coil on the cantilever, adjust the height of the cantilever to keep the coil and the steel pipe at the same center height and ensure the gap between the coil and the steel pipe Evenly, connect the coil and the intermediate frequency equipment with water cables, after the intermediate frequency equipment is powered on and watered;

[0053] 2) Start the intermediate frequency heating equipment. After the steel pipe is heated, the temperature is 200℃~220℃, the time is 60min, the intermediate frequency voltage is 600V, and the DC current is 870A;

[0054] 3) Adjust the roller spacing of the transfer trolley to 1130mm, the roller speed to 7r / min, and the travel speed of the transfer trolley to 200mm / min;

[0055] 4) The tube transfer trolley moves forward evenly at the set speed, and starts to heat the steel pipe....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com