Aviation aluminium alloy U-shaped frame section bar and preparation method thereof

An aluminum alloy and U-shaped technology, which is applied in the field of aerospace aluminum alloy U-shaped frame profiles and its preparation, can solve problems such as uneven bending arcs, low production efficiency, and uneven manual processing areas, and achieve breakthroughs in precision bottlenecks, Good plane flatness, ensure the effect of stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

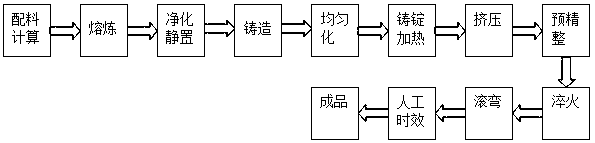

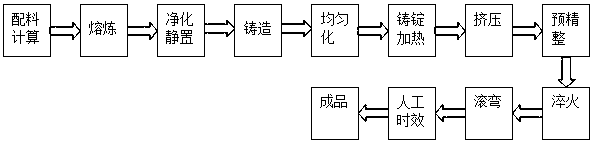

Method used

Image

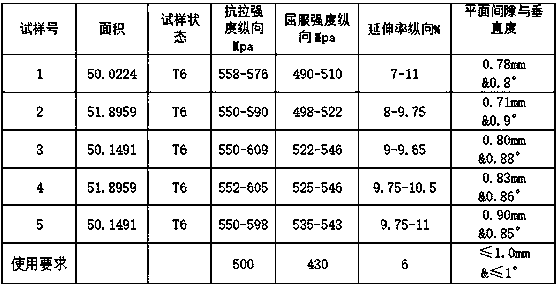

Examples

Embodiment 1

[0028] An aluminum alloy U-shaped frame profile for aerospace, which is composed of the following elements in weight percentage: Zn5.6%, Cu2.4%, Mn<0.1%, Mg1.8%, Cr0.25%, Fe0.25%, Si≤0.1%, Ti<0.08%, and the balance is Al.

[0029] The preparation method of the aluminum alloy U-shaped frame profile for aerospace comprises the following steps:

[0030] (1) Select remelted aluminum ingots, zinc ingots, magnesium ingots, electrolytic copper plates, Al-4Cr alloys, and Al-10Fe alloys with a grade ≥99.85% as raw materials according to the composition of elements;

[0031] (2) Use a resistance reverberatory furnace to melt remelted aluminum ingots, Al-4Cr alloys, and Al-10Fe alloys at 700 ° C. After melting, add zinc ingots, magnesium ingots and electrolytic copper plates into the melt, and stir and melt to form an alloy melt;

[0032] (3) Use nitrogen-chlorine mixed gas blowing method to purify the melt, and the ratio of nitrogen-chlorine mixed gas is N 2 =84%, Cl 2 =16%, blowing ...

Embodiment 2

[0040] An aluminum alloy U-shaped frame profile for aerospace, which is composed of the following elements in weight percentage: Zn6.0%, Cu2.0%, Mn<0.1%, Mg2.2%, Cr0.22%, Fe0.30%, Si≤0.1%, Ti<0.08%, and the balance is Al.

[0041] The preparation method of the aluminum alloy U-shaped frame profile for aerospace comprises the following steps:

[0042] (1) Select remelted aluminum ingots, zinc ingots, magnesium ingots, electrolytic copper plates, Al-4Cr alloys, and Al-10Fe alloys with a grade ≥99.85% as raw materials according to the composition of elements;

[0043] (2) Use a resistance reverberatory furnace to melt remelted aluminum ingots, Al-4Cr alloys, and Al-10Fe alloys at 760 ° C. After melting, add zinc ingots, magnesium ingots and electrolytic copper plates into the melt, and stir and melt to form an alloy melt;

[0044] (3) Use nitrogen-chlorine mixed gas blowing method to purify the melt, and the ratio of nitrogen-chlorine mixed gas is N 2 =84%, Cl 2 =16%, blowing ...

Embodiment 3

[0052] An aluminum alloy U-shaped frame profile for aerospace, which is composed of the following elements in weight percentage: Zn6.5%, Cu1.4%, Mn<0.1%, Mg2.6%, Cr0.2%, Fe0.35%, Si≤0.1%, Ti<0.08%, and the balance is Al.

[0053] The preparation method of the aluminum alloy U-shaped frame profile for aerospace comprises the following steps:

[0054] (1) Select remelted aluminum ingots, zinc ingots, magnesium ingots, electrolytic copper plates, Al-4Cr alloys, and Al-10Fe alloys with a grade ≥99.85% as raw materials according to the composition of elements;

[0055] (2) Use a resistance reverberatory furnace to melt remelted aluminum ingots, Al-4Cr alloys, and Al-10Fe alloys at 730°C. After melting, add zinc ingots, magnesium ingots, and electrolytic copper plates into the melt, and stir and melt to form an alloy melt;

[0056] (3) Use nitrogen-chlorine mixed gas blowing method to purify the melt, and the ratio of nitrogen-chlorine mixed gas is N 2 =84%, Cl 2 =16%, the blowin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com