Trepanning pup joint for oil-gas pipeline

A technology for oil and gas pipelines and short joints, which is applied in the field of drilling short joints of oil and gas pipelines, can solve the problems of large welding workload, corrosion of guard plates, and heavy quality, and achieves the advantages of reducing welding workload, reducing welding volume, and reducing stress concentration. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

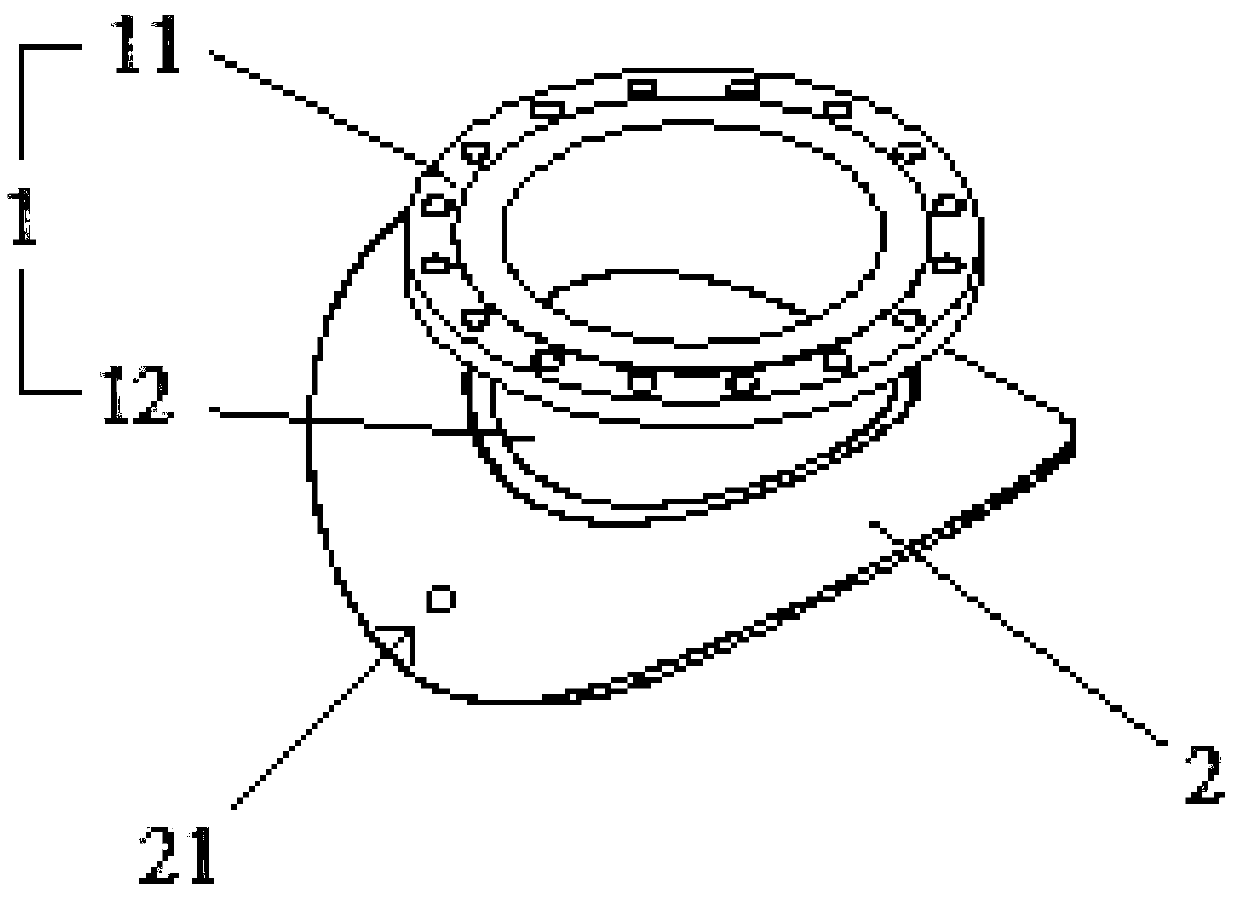

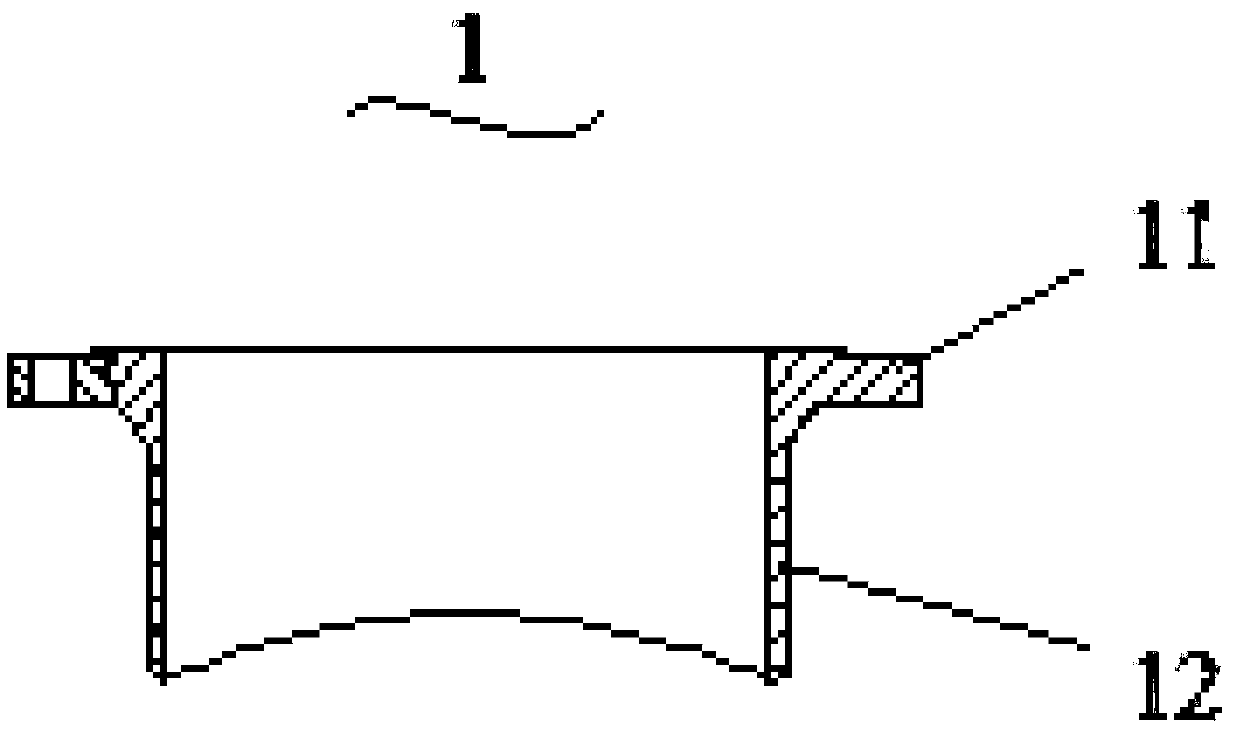

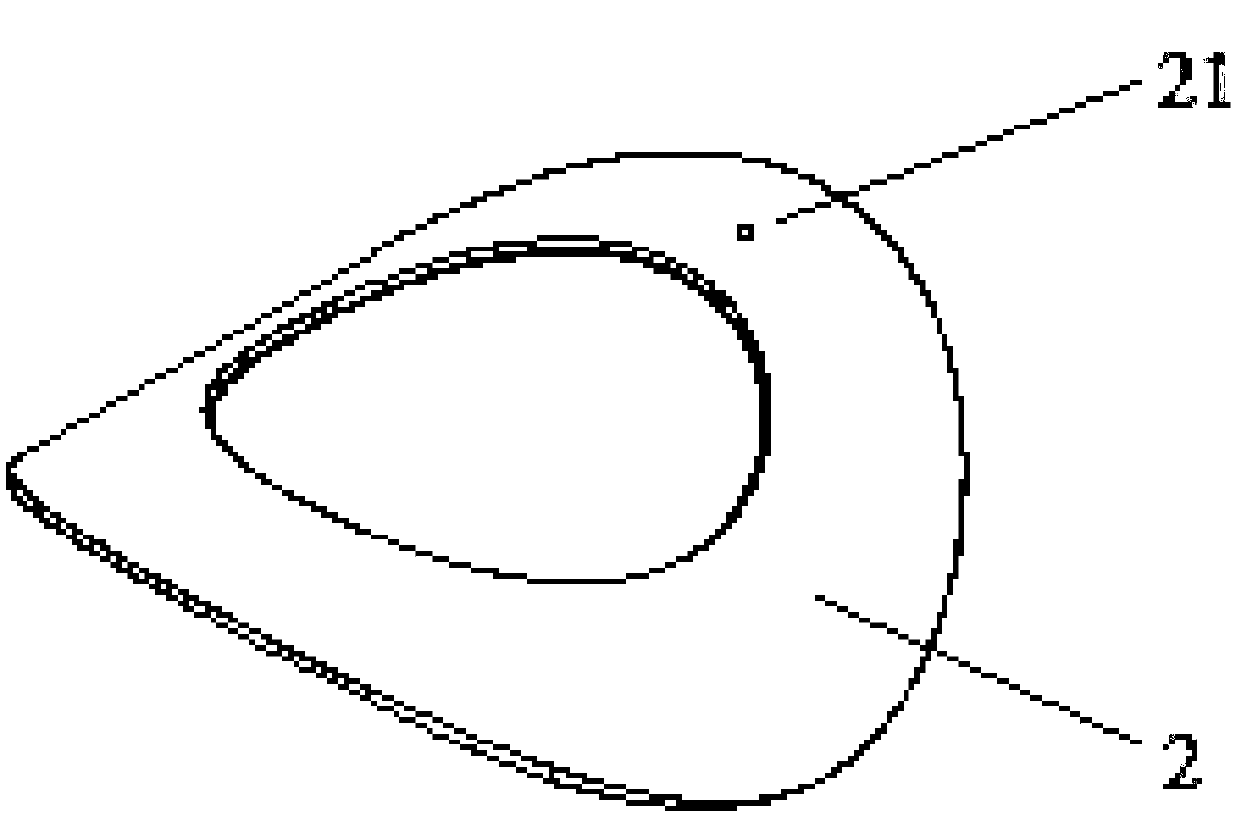

[0029] In the first aspect, the embodiment of the present invention provides an oil and gas pipeline opening pup joint, such as figure 1 As shown, the opening pup joint includes: an external flange 1 and a reinforcing plate 2 in a ring structure; the external flange 1 includes: a flange 11, and the first end is sleeved in the flange 11 and fixed The connected long-necked pipe 12; the second end of the long-necked pipe 12 can be sleeved in the reinforcing plate 2; the reinforcing plate 2 has a surface that can fit on the outer wall of the oil and gas pipeline.

[0030] The principle of using the oil and gas pipeline opening pup joint provided by the embodiment of the present invention is as follows:

[0031] When in use, the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com