Heating and vacuum desorption combined adsorber and adsorption and desorption method and application

An adsorber and combined technology, applied in chemical instruments and methods, separation methods, adsorption water/sewage treatment, etc., can solve problems such as uneven heat transfer, deformation and insufficiency of adsorber materials, and achieve the reduction of adsorber materials Effects of deformation, stress concentration relief, and pressure drop equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

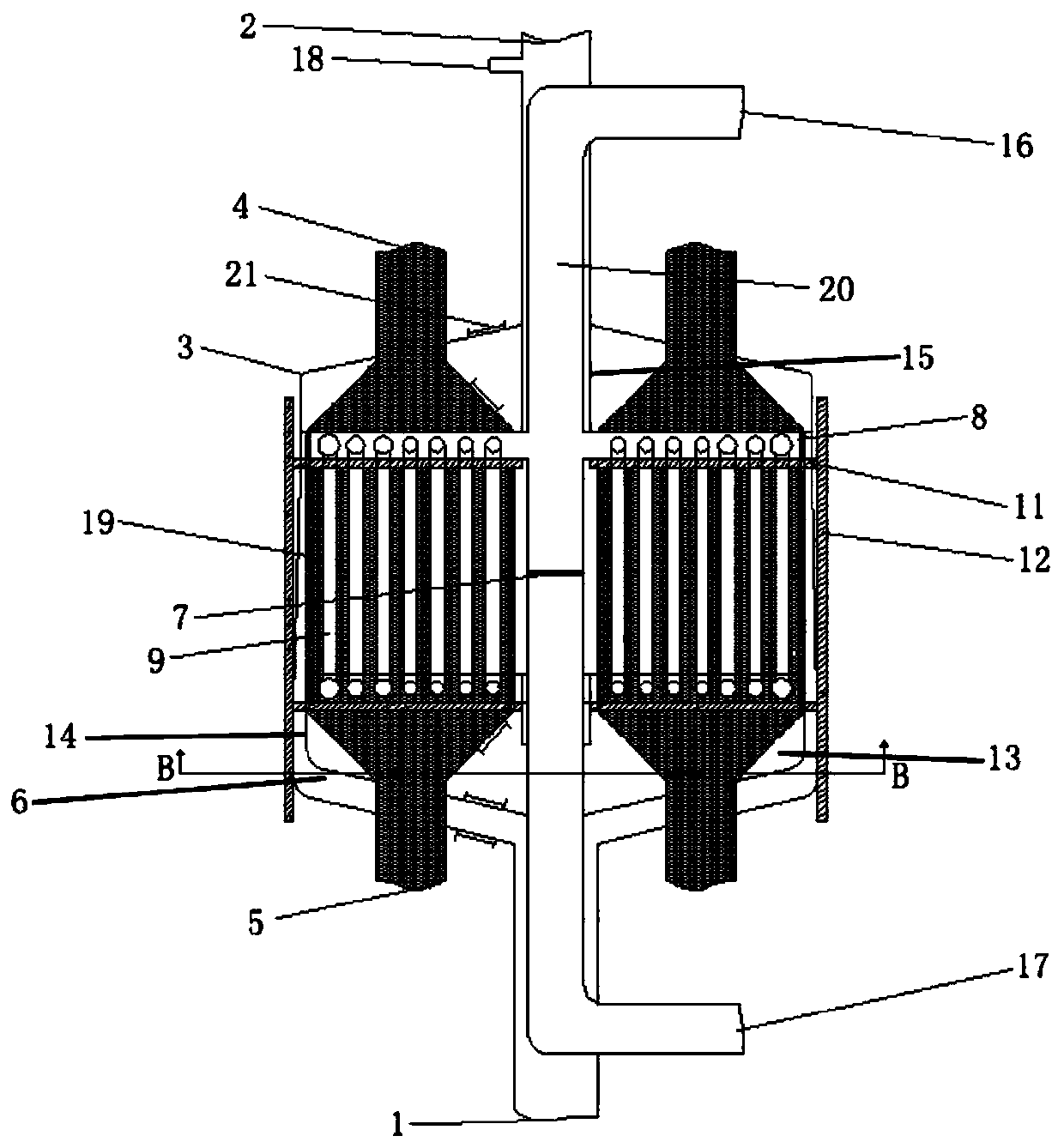

[0101] This embodiment proposes an adsorber that combines heating and vacuum desorption, and the adsorber includes:

[0102] An adsorber housing, the upper end of the adsorber housing is provided with an adsorption fluid outlet and an adsorption material inlet, and the lower ends are provided with an adsorption fluid inlet and an adsorption material outlet;

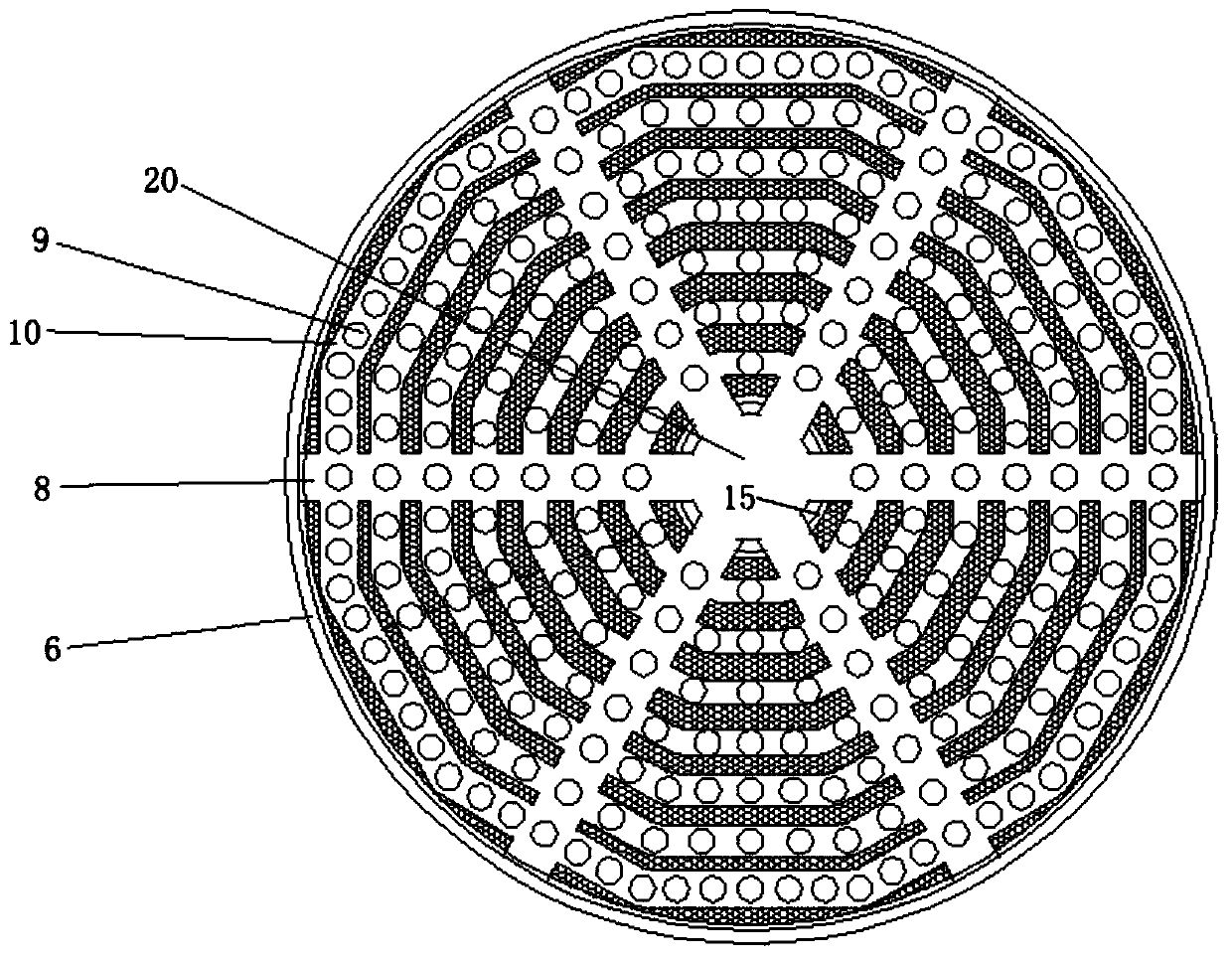

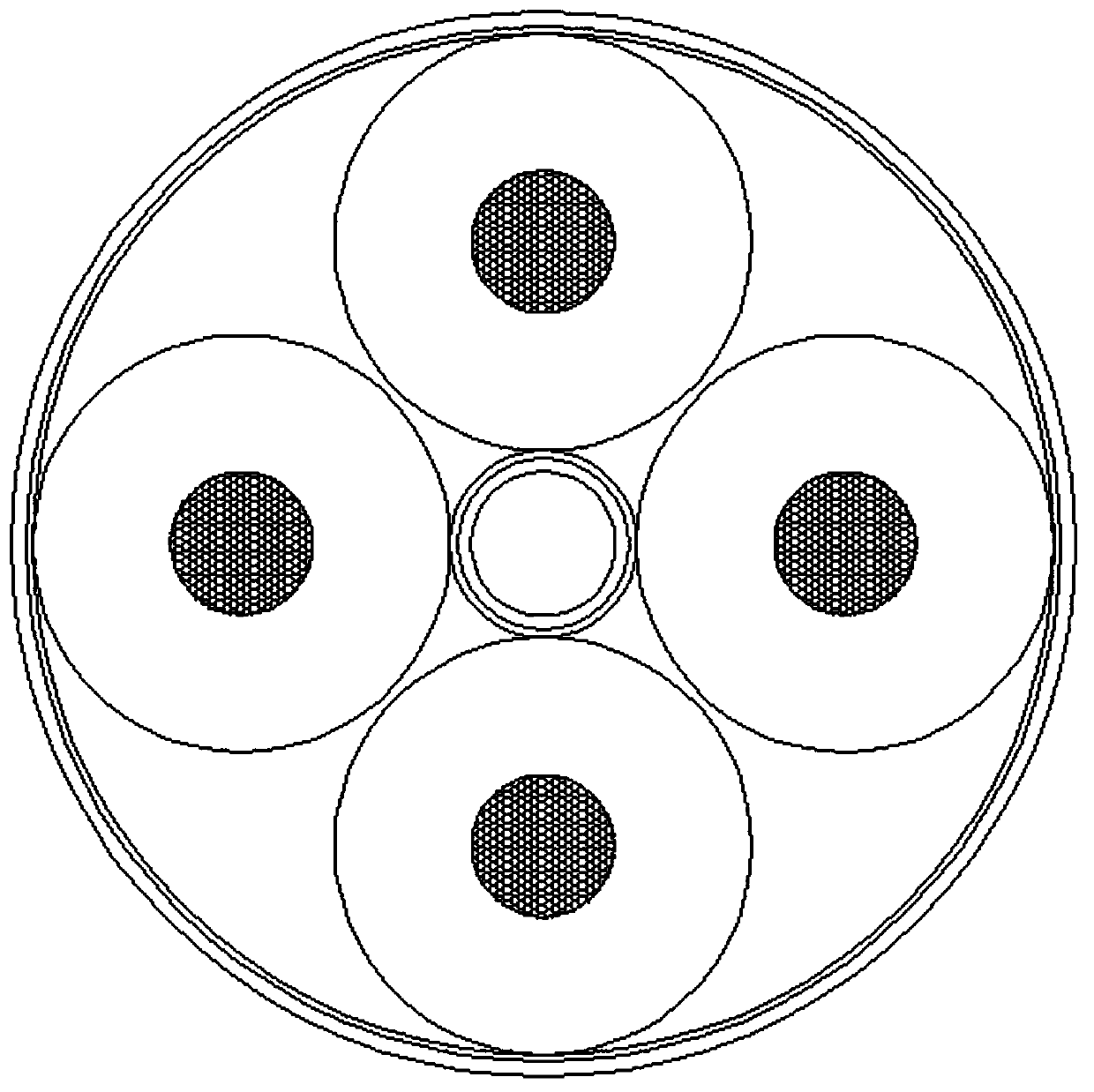

[0103] The middle shell layer is used to fill the adsorption material and cooperate with the outer shell of the adsorber and the heat exchange medium pipeline unit to divide the inside of the adsorber into an adsorption fluid flow channel and a heat exchange medium flow channel. The adsorption fluid flow channel and the heat exchange medium flow channel The heat medium channel is not connected;

[0104] The heat exchange medium pipeline unit is used to circulate the heat exchange medium to heat and desorb the adsorption material;

[0105] The cross-section of the intermediate shell is annular, including an inner wall and a...

Embodiment 2

[0151] This embodiment provides a method for adsorption and desorption of an adsorber that combines heating and vacuum desorption. The method uses the adsorber that combines heating and vacuum desorption provided in Example 1. The method includes:

[0152] The adsorption material is adsorbed, and the adsorption fluid enters from the adsorption fluid inlet, passes through the adsorption fluid flow channel, and after being adsorbed by the adsorption material of the middle shell, the remaining adsorption fluid is discharged from the adsorption fluid outlet;

[0153] Indirectly heating the desorption adsorption fluid, the heat exchange medium passes through the heat exchange medium pipe unit, and indirectly heats the adsorption material in the middle shell, so that the adsorption material is desorbed;

[0154] Vacuum desorption, vacuumizing the adsorption fluid channel to desorb the adsorption material.

[0155] The method also includes:

[0156] cooling the adsorption material; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com