Hydraulic power device of dual-axis shearing type crusher

A hydraulic power unit and shearing technology, applied in the field of hydraulic power system, can solve the problems of unreasonable structural design of hydraulic station, unfavorable heat dissipation and maintenance, affecting production progress, etc., to achieve favorable heat dissipation and maintenance, compact structure, and guaranteed production effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

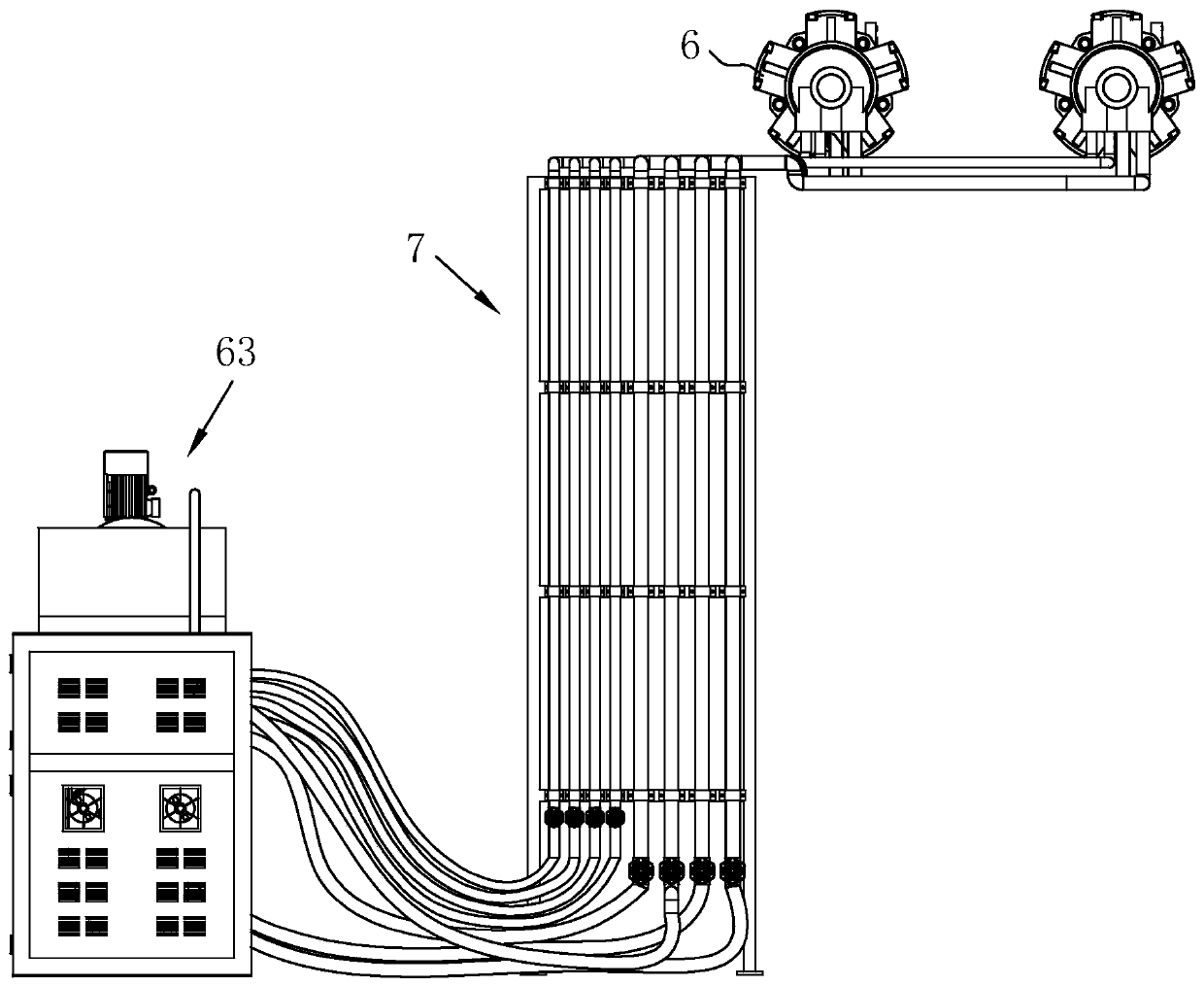

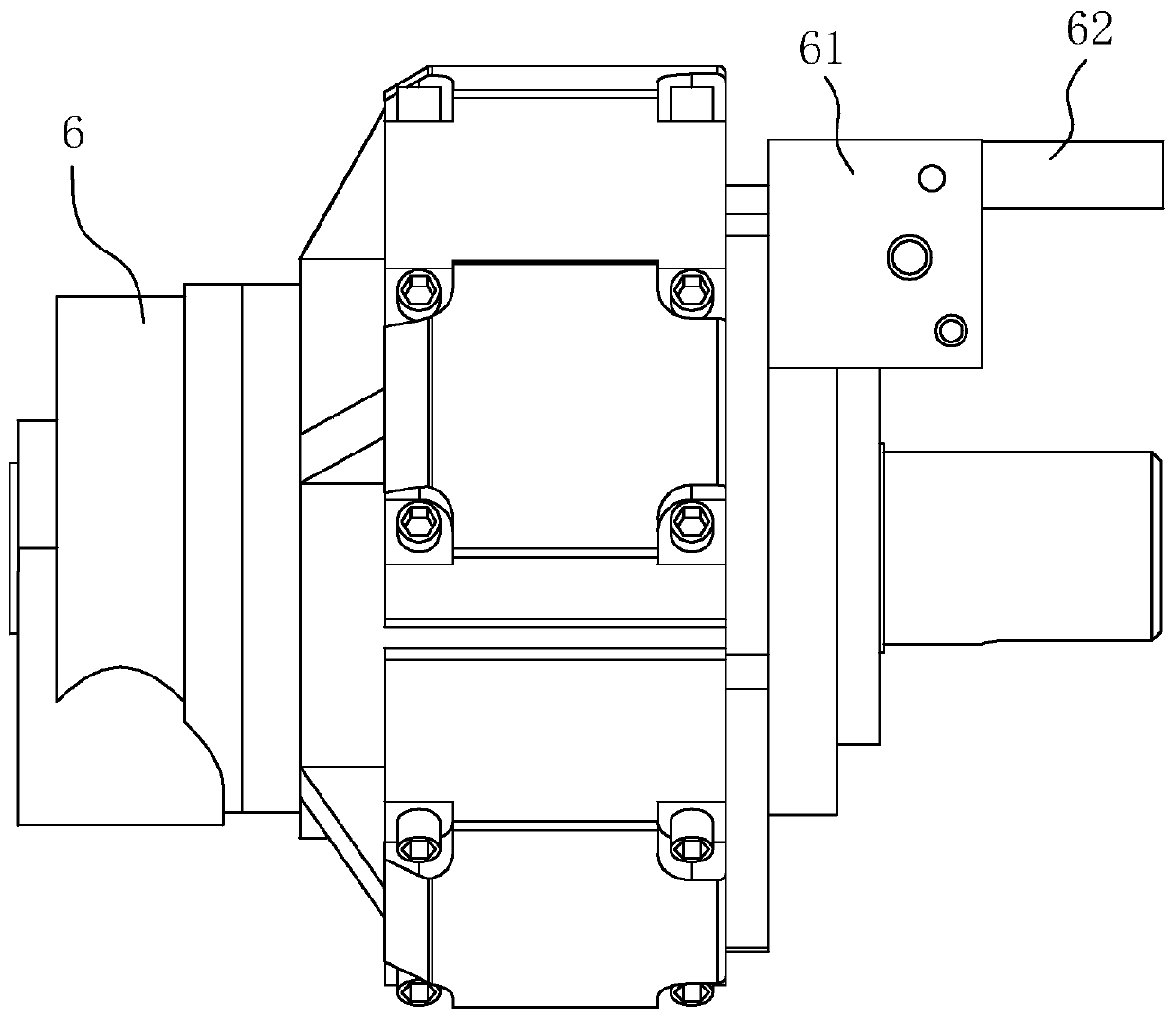

[0053] refer to figure 1 , is a hydraulic power device for a twin-shaft shearing crusher disclosed in the present invention, including a closed hydraulic station 63 , an external pipeline 7 and two hydraulic motors 6 . The hydraulic motor 6 is connected to the closed hydraulic station 63 through the external pipeline 7, and the hydraulic motor 6 directly drives the cutter shaft of the crusher in forward and reverse directions to realize crushing of materials.

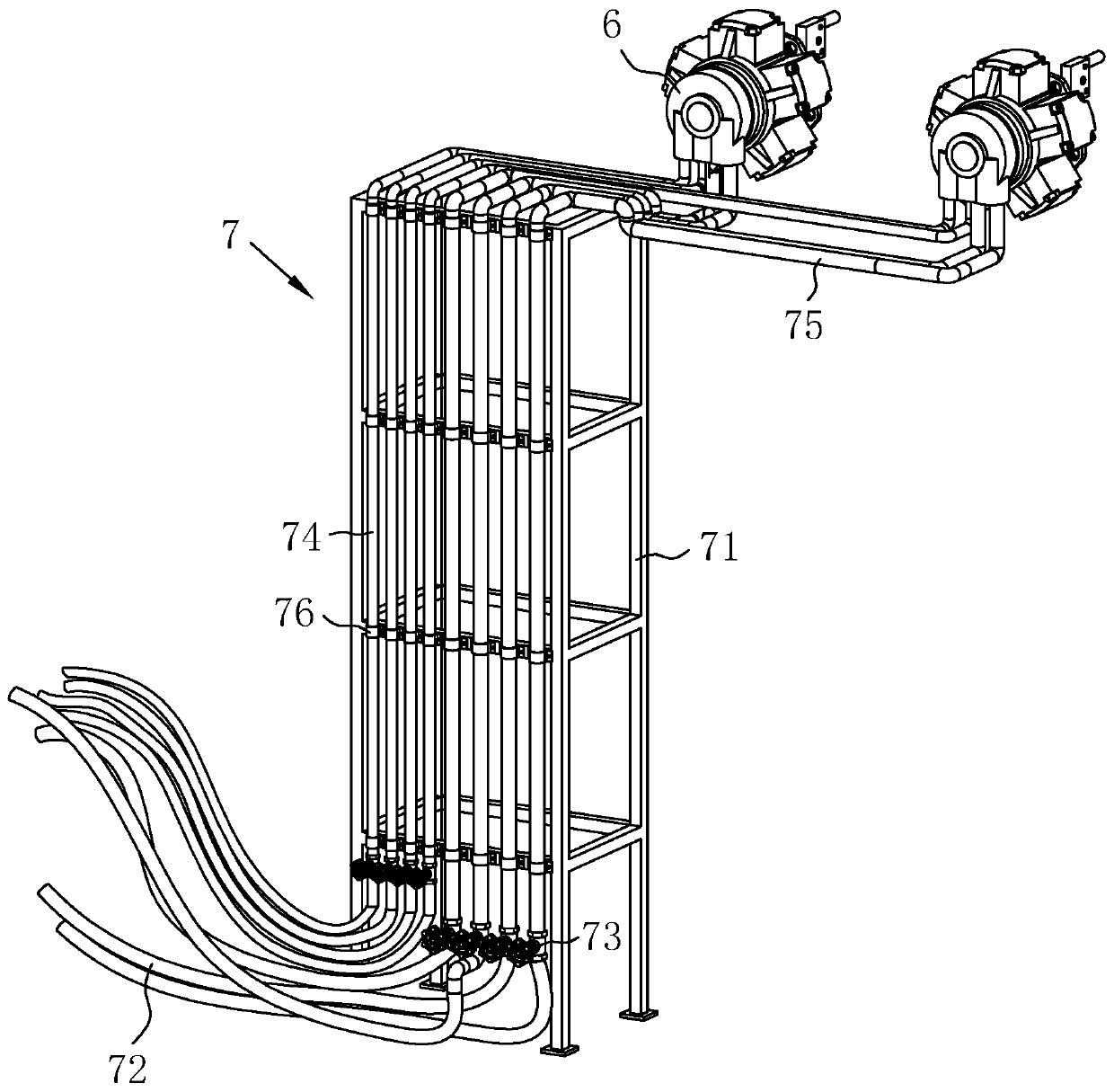

[0054] refer to figure 1 and figure 2 , the external pipeline 7 includes a front-end hose assembly 72 , a high-pressure ball valve 73 , a hard pipe assembly 74 , a pipe clamp 76 , a support frame assembly 71 and a rear-end hose assembly 75 . One end of the external pipeline 7 is connected to the closed hydraulic station 63 through the front end hose assembly 72 , and the other end is connected to the hydraulic motor 6 through the rear end hose assembly 75 . A high-pressure ball valve 73 is connected between the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com