Unmanned automatic rust removing and spraying device for inner wall of storage tank

A spraying device and storage tank technology, which is applied in the field of unmanned automatic derusting and spraying devices, can solve the problems of narrow entrance and exit of manholes, no inner walls of storage tanks, and low automation, so as to reduce occurrence factors, reduce injuries, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

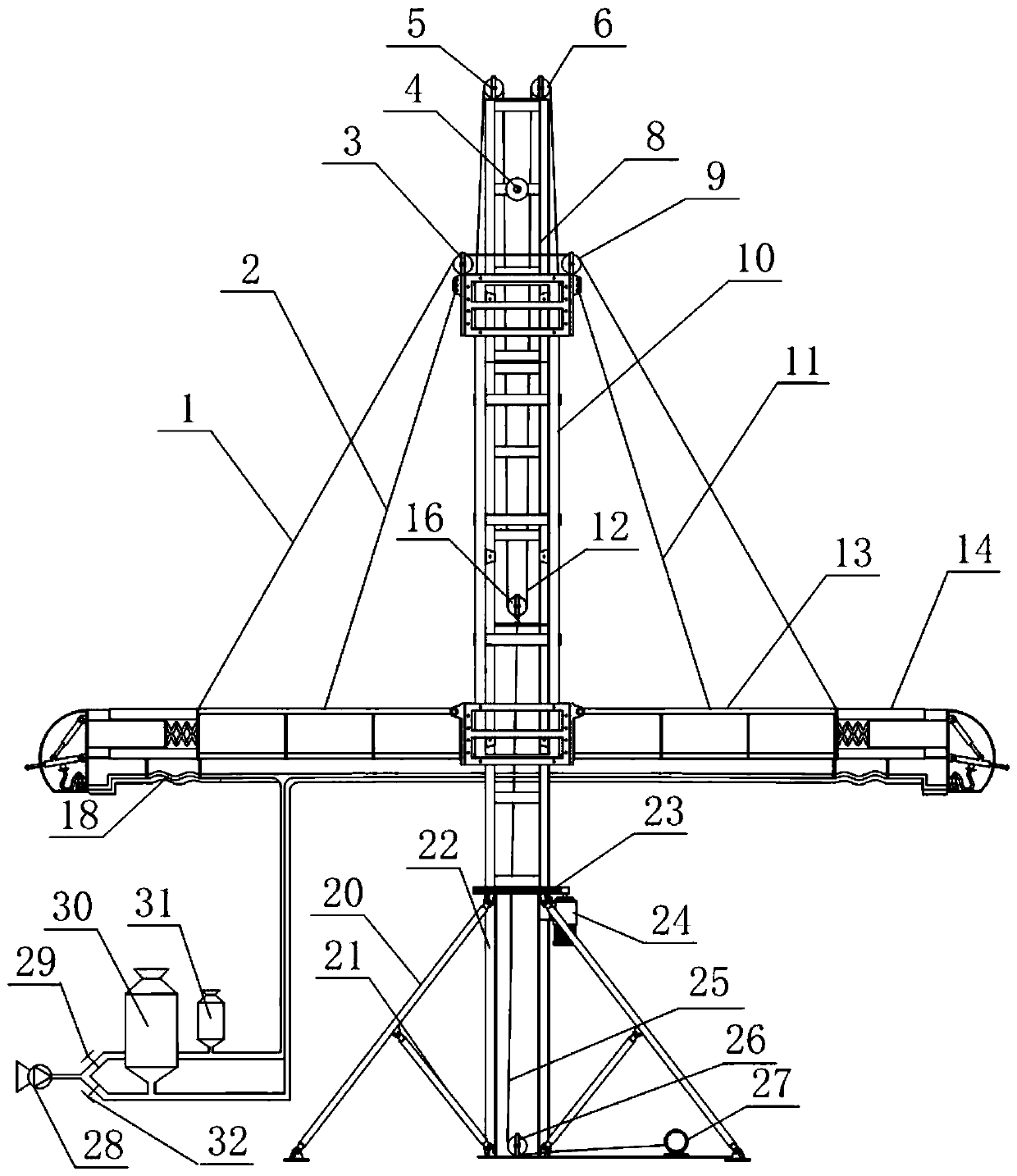

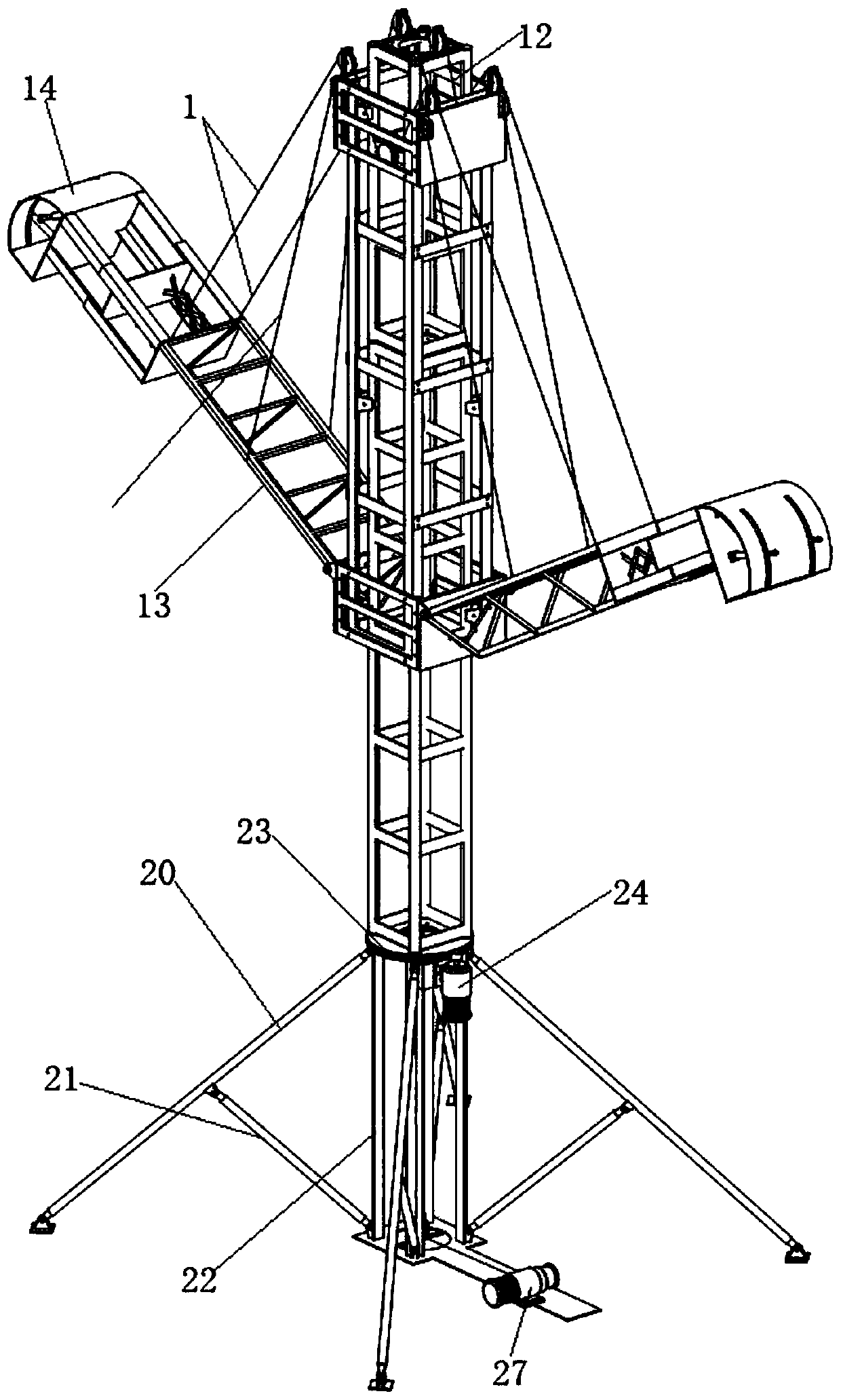

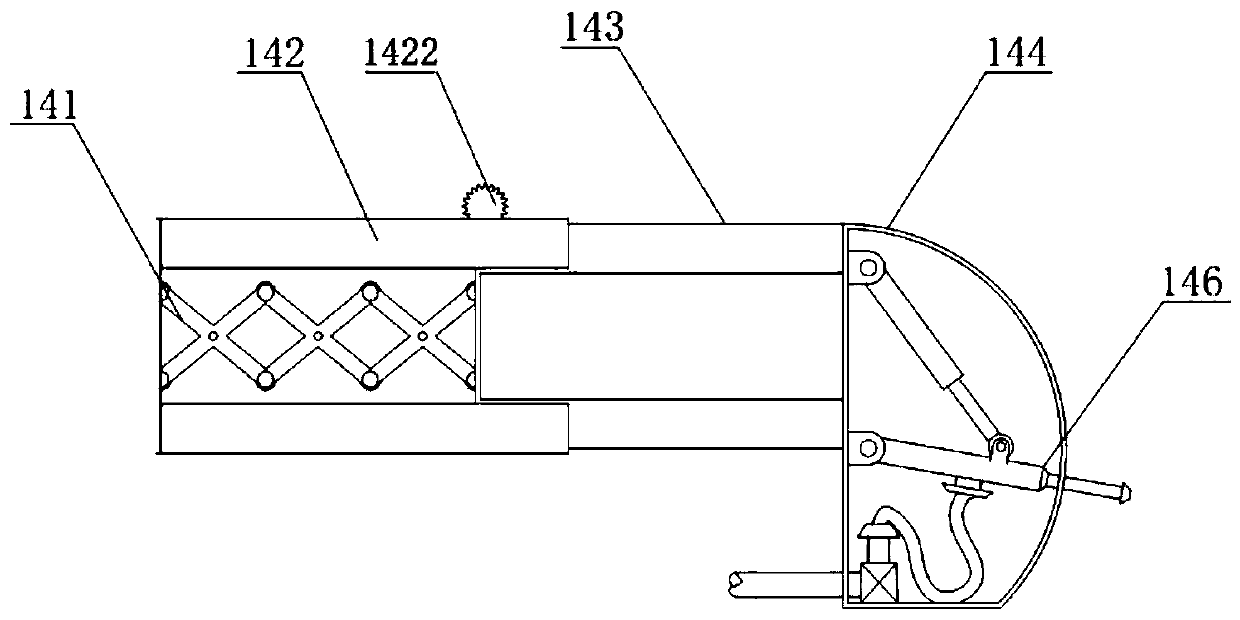

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 with Figure 5 As shown, an unmanned automatic derusting and spraying device for the inner wall of the storage tank of the present invention is arranged in the storage tank, and it includes a fixed base 22 and a column 8. A drive assembly, the drive assembly includes a turntable bearing 23 located between the fixed base 22 and the column 8, the inner ring of the turntable bearing 23 is fixedly connected to the fixed base 22, the outer ring is connected to the column 8, and the outer ring is evenly distributed with teeth , is connected with drive motor 24 by gear. The column 8 is provided with a lifting outer frame 10, the lifting outer frame 10 is connected to a driving mechanism, and the driving mechanism is used to drive the lifting outer frame 10 to move up and down along the column 8. Specifically, the driving mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com