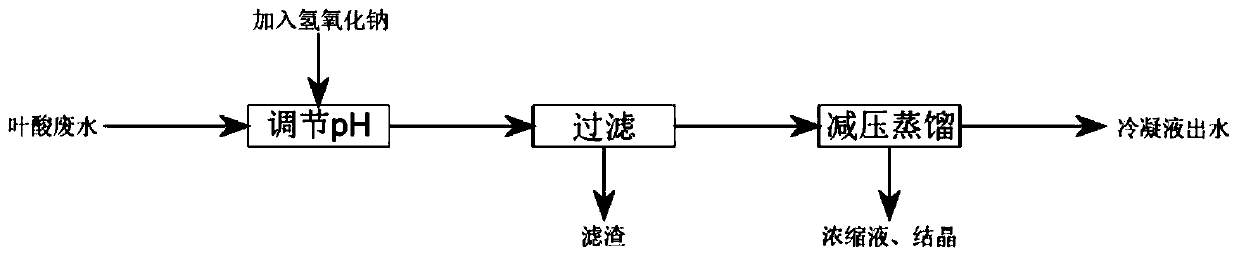

Method for treating folic acid wastewater

A treatment method and technology for wastewater, applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problems of complex operation, high energy consumption and high cost, and achieve a simple operation method, low cost and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, take 200ml of folic acid wastewater, the pH of folic acid wastewater is 0.5, the COD value is 2000mg / L, the ammonia nitrogen value is 210mg / L, and the total dissolved solids is 25000mg / L; add sodium hydroxide, adjust the pH to 4.3, and obtain the solution; then, pour the solution to be treated into the filter tank, and filter it with a filter membrane of 0.45 μm; after the filtration is completed, obtain the filtrate; then pour the filtrate into the rotary evaporator to ensure that the pressure is controlled at 0.04Mpa and the temperature is 80 °C, the concentration rate is 50%, and after the distillation is completed, a condensate is obtained, that is, effluent is obtained.

[0029] Measure the content of COD, ammoniacal nitrogen and TDS in the effluent of Example 1, wherein the removal rate of COD is 97.9%, the extraction rate of ammoniacal nitrogen is 93.9%, and the removal rate of TDS is greater than 99%.

Embodiment 2

[0031] First, take 100ml of folic acid wastewater, the pH of folic acid wastewater is 1.1, the COD value is 9500mg / L, the ammonia nitrogen value is 330mg / L, and the total dissolved solids is 42000mg / L; add sodium hydroxide, adjust the pH to 4.2, and obtain the solution; then, pour the solution to be treated into the filter tank, and filter it with a 0.22 μm filter membrane; after the filtration is completed, obtain the filtrate; then pour the filtrate into a rotary evaporator to ensure that the pressure is controlled at 0.06Mpa and the temperature is 90 °C, the concentration rate is 60%, and after the distillation is completed, a condensate is obtained, that is, effluent is obtained.

[0032] Measure the content of COD, ammoniacal nitrogen and TDS in the effluent of Example 2, wherein the removal rate of COD is 99.4%, the extraction rate of ammoniacal nitrogen is 95.7%, and the removal rate of TDS is greater than 99%.

Embodiment 3

[0034] First, take 500ml of folic acid wastewater, the pH of folic acid wastewater is 2.3, the COD value is 30000mg / L, the ammonia nitrogen value is 600mg / L, and the total dissolved solids is 60000mg / L; add sodium hydroxide, adjust the pH to 4.0, and obtain solution; then, pour the solution to be treated into the filter tank, and filter it with a filter membrane of 0.45 μm; after the filtration is finished, obtain the filtrate; then pass the filtrate into the MVR reactor to ensure that the pressure is controlled at 0.05Mpa and the temperature is 85 °C, the concentration rate is 50%, and after the distillation is completed, a condensate is obtained, that is, effluent is obtained.

[0035] Measure the content of COD, ammoniacal nitrogen and TDS in the effluent of Example 3, wherein the removal rate of COD is 99.8%, the extraction rate of ammoniacal nitrogen is 98.5%, and the removal rate of TDS is greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com