Preparation method of SiO2 micro-nanosphere and micro-reaction system

A micro-nanosphere and microreaction technology, applied in nanotechnology, silicon dioxide, silicon oxide, etc., can solve the problems of low mass transfer mixing and dispersion strength, limiting the application of microreactors, and uneven microsphere particles, etc. Stable product performance, high processing cost and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

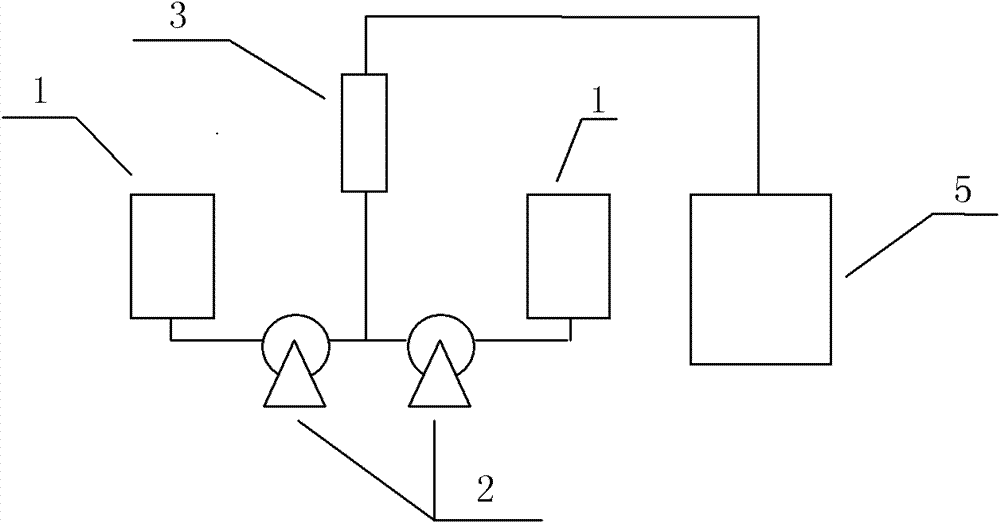

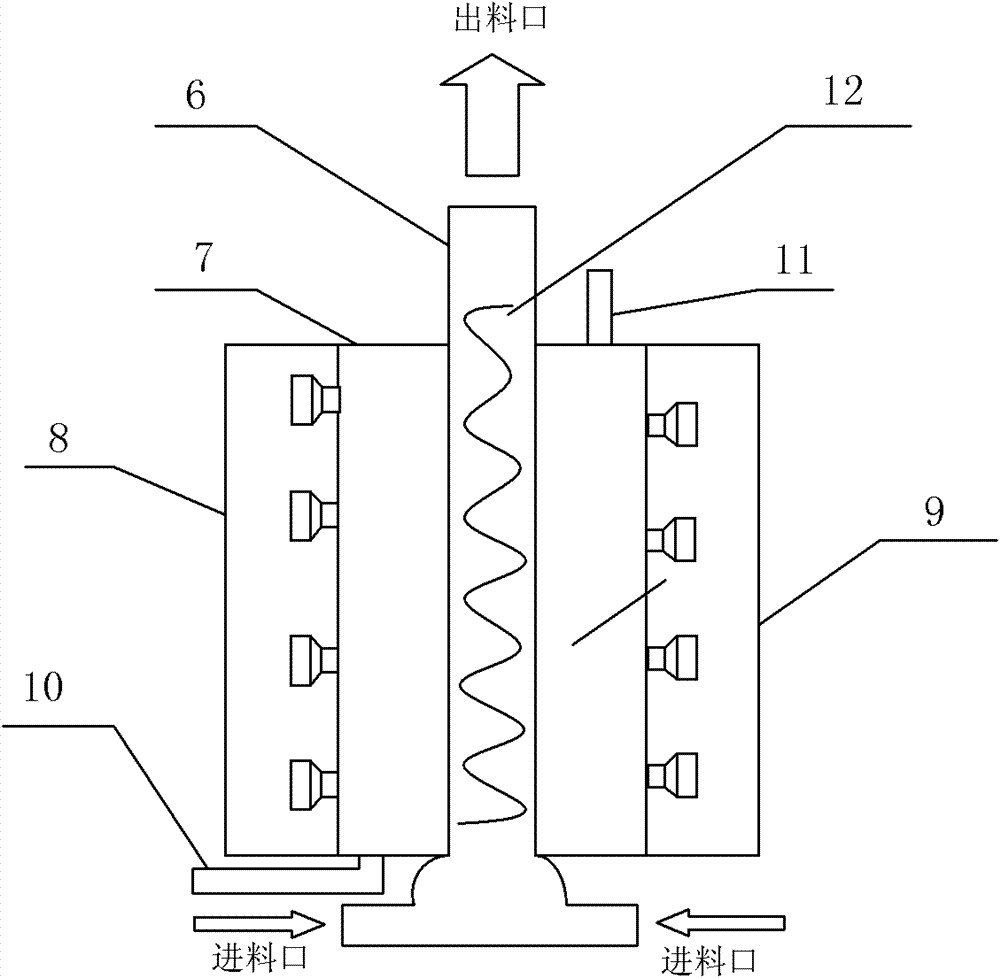

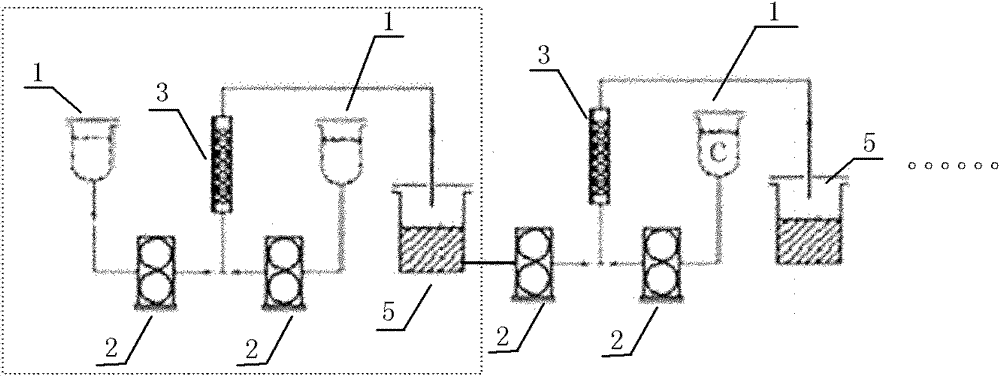

[0032]This example provides a kind of micro reaction system, comprises a unit reaction device, and described unit reaction device is made up of feeding device, strengthened micro reaction device 3 and storage tank 5, and described feeding device is made up of liquid tank 1 and constant flow The pump 2 is connected to form, and the enhanced micro-reaction device 3 includes a micro-reactor 6 and an ultrasonic generator 9 staggered outside the reactor 6; The feed tank 5 is connected to the discharge port of the enhanced micro-reaction device 3 through a connecting pipe. Further, the enhanced micro-reaction device 3 also includes an ultrasonic groove, the ultrasonic groove surrounds the outside of the micro-reactor 6, and the ultrasonic generator 9 is installed in the ultrasonic groove. The ultrasonic tank is composed of an inner tank 7 and an outer tank 8 connected together. The ultrasonic generators 9 are evenly staggered and installed in the outer tank 8; the entire microreacto...

Embodiment 2

[0038] The two reaction unit devices described in Embodiment 1 are combined into a micro-reaction system according to the series connection. In the two liquid tanks of the first reaction unit device, an absolute ethanol solution with a molar concentration of tetraethyl orthosilicate of 0.8 mol / L, and a water molar concentration of 8 mol / L and an ammonia molar concentration of 1.6 mol / L are respectively arranged. mixed solution of absolute ethanol. Similarly, an absolute ethanol solution having a molar concentration of ethyl orthosilicate of 0.4 mol / L was configured in the liquid tank of the second reaction unit device. Then pass 30°C circulating water into the enhanced micro-reaction device of the first reaction unit device, and turn on and adjust the ultrasonic frequency to 25KHz, and the ultrasonic power to 200W, then turn on the two constant flow pumps of the first reaction unit device, and Control the flow rate of the two solutions to be 1.2L / min. After the reaction was ...

Embodiment 3

[0040] The four reaction unit devices described in Embodiment 1 are combined into a micro-reaction system according to the series connection. In the two liquid tanks of the first reaction unit device, configure an anhydrous ethanol solution with a molar concentration of tetraethyl orthosilicate of 1.0 mol / L, and an ethanol solution with a molar concentration of water of 11 mol / L and a molar concentration of ammonia of 2.1 mol / L. Anhydrous ethanol mixed solution. Similarly, in the liquid tank of the second reaction unit device, the molar concentration of ethyl orthosilicate is an absolute ethanol solution of 0.3mol / L, and the molar concentration of ethyl orthosilicate is configured in the liquid tank of the third reaction unit device. It is 0.45mol / L dehydrated ethanol solution, and the dehydrated ethanol solution whose molar concentration of ethyl tetrasilicate is 0.6mol / L is arranged in the liquid tank of the fourth reaction unit device. Then pass 35°C circulating water into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com