Electrode water jacket for electric smelting furnace and installation method of electrode water jacket

An installation method and technology of electric melting furnace, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of loss of refractory protection, bubbling phenomenon, water jacket head damage, etc., to prolong the service life and prolong the furnace. life, the effect of reducing unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

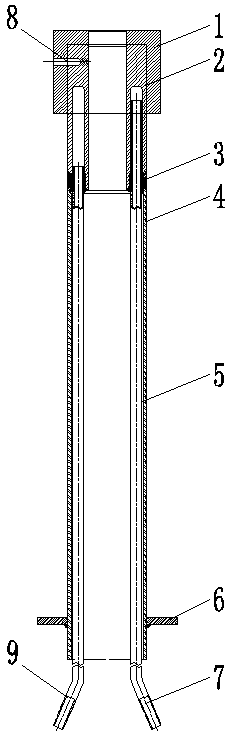

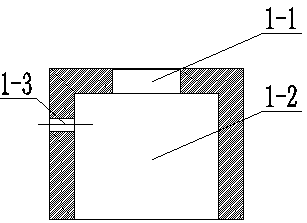

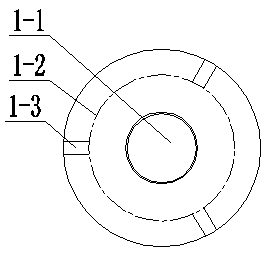

[0046] What is more important in the present invention is the protection of the water jacket protective cover 1 to prevent oxidation. The method adopted includes the following steps: sprinkle 3-5mm thick glass powder in the stepped hole of the electrode brick 10, and put the water jacket protective cover 1 on when the installation is completed. Apply a layer of terpineol evenly on the outside, and then paste the glass powder evenly on the outer wall of the water jacket protective cover 1, and then wrap it evenly with glass cloth from bottom to top. As the temperature rises, the glass powder and glass cloth It will melt and wrap on the surface of the water jacket protective cover 1 to prevent oxidation. The water jacket protective cover 1 and the assembled water jacket are lowered to the corresponding positions of the stepped holes, and then the gap between the water jacket protective cover 1 and the electrode brick is filled with glass powder ; After installing the electrode, f...

Embodiment 2

[0048] More important in the present invention is the protection of the water jacket protective cover 1 to prevent oxidation. Another method adopted includes the following steps: the outer surface of the water jacket protective cover 1 is provided with a high-temperature resistant ceramic insulating coating layer to prevent the water jacket protective cover from 1 oxidation purpose, then repeat the steps of the method of Example 1.

[0049] In the above two embodiments, according to the temperature range of the molten glass, the water jacket protective cover 1 selects molybdenum, a metal material that can withstand the scouring of the molten glass and withstand higher temperatures. Molybdenum can withstand a high temperature of 2610 degrees. It can operate at a safe temperature in the molten glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com