Polytetrafluoroethylene bubble point film, and preparation method thereof

A polytetrafluoroethylene and bubble point technology, which is applied in the field of polytetrafluoroethylene bubble point film and its preparation, can solve the problem that the sterilization effect cannot be satisfied, and achieves excellent sterilization performance, good pore size stability, and is not easy to shrink and deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

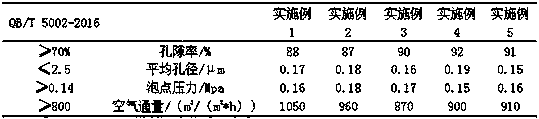

Examples

Embodiment 1

[0031] A preparation method of polytetrafluoroethylene, comprising the following steps: mixing, curing, embryo pressing, pressing, calendering and biaxial stretching, and further comprising a heat setting step after biaxial stretching, and the heat setting temperature is 320° C., The time of heat setting is 30s, and the cooling rate of heat setting is 20°C / min; wherein, the mixing process is: adding polytetrafluoroethylene resin a and polytetrafluoroethylene resin b into the double cone mixer, First rotate clockwise for 10 minutes, then counterclockwise for 10 minutes, and the mixing temperature is 10 °C; the biaxial stretching process is: firstly, longitudinal stretching with a stretching ratio of 3 times is performed, and then transverse stretching with a stretching ratio of 5 times is carried out. ; Aging temperature of 60 ℃.

[0032] Use raw material 1 to mix.

Embodiment 2

[0034] A preparation method of polytetrafluoroethylene, comprising the following steps: mixing, curing, embryo pressing, pressing, calendering and biaxial stretching, and further comprising a heat setting step after the biaxial stretching, and the temperature of the heat setting is 340 DEG C, The time of heat setting is 60s, and the cooling rate of heat setting is 70°C / min; wherein, the mixing process is: adding polytetrafluoroethylene resin a and polytetrafluoroethylene resin b into the double cone mixer, Rotate clockwise for 30 minutes first, stand still for 5 minutes, then rotate counterclockwise for 30 minutes, and the mixing temperature is 20 °C; the biaxial stretching process is: firstly, longitudinal stretching with a stretching ratio of 10 times is carried out, and then a stretching ratio of 12 times is carried out. Transverse stretching; aging temperature is 90 ℃.

[0035] Use raw material 2 to mix.

Embodiment 3

[0037] A preparation method of polytetrafluoroethylene, comprising the following steps: mixing, curing, embryo pressing, pressing, calendering and biaxial stretching, and further comprising a heat setting step after biaxial stretching, and the temperature of the heat setting is 330 DEG C, The time of heat setting is 50s, and the cooling rate of heat setting is 50°C / min; wherein, the mixing process is: adding polytetrafluoroethylene resin a and polytetrafluoroethylene resin b into the double cone mixer, Rotate clockwise for 20 minutes first, stand still for 3 minutes and then rotate counterclockwise for 20 minutes, and the mixing temperature is 15 °C; the biaxial stretching process is: firstly, longitudinal stretching with a stretching ratio of 5 times is carried out, and then a stretching ratio of 8 times is carried out. Transverse stretching; aging temperature is 80 ℃.

[0038] Use raw material 3 to mix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com