Carding machine for improving the quality of cotton web of aramid nonwoven fabric and its application method

A technology for non-woven fabrics and carding machines, applied in the field of carding machines, can solve problems such as poor electrostatic removal effect and easy damage to product quality, and achieve the effects of damaging product quality, enhancing electrostatic removal effect, and improving humidification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

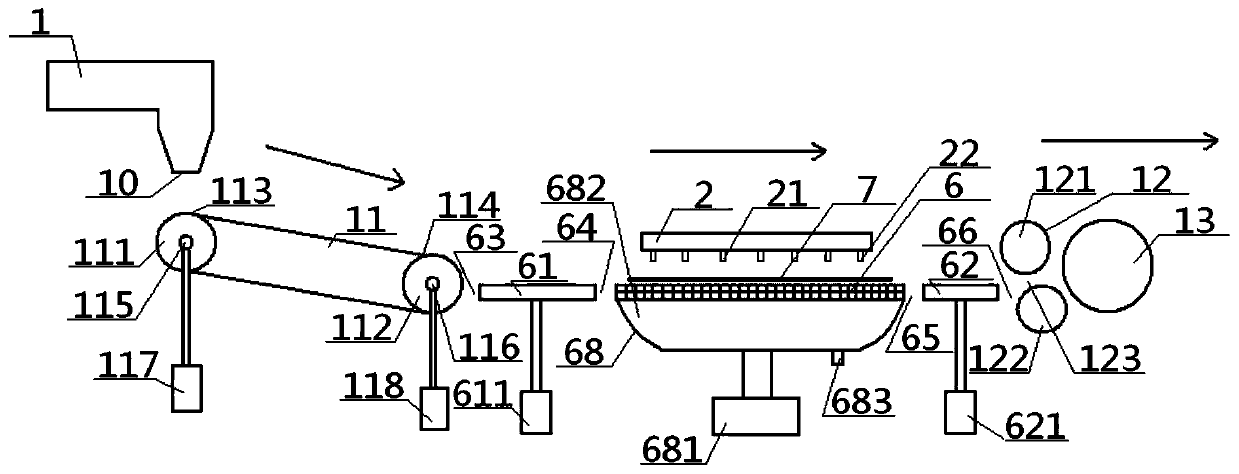

[0050] see Figure 1 to Figure 8 , a carding machine for improving the quality of aramid nonwoven cotton web, comprising a raw material box 1, a cotton feeding curtain 11, a feeding roller 12 and an opening roller 13, the front and rear ends of the cotton feeding curtain 11 are respectively provided with front Curtain roller 111 and rear curtain roller 112, described feeding roller 12 comprises upper roller 121, lower roller 122 and the roller channel 123 sandwiched between the two, the discharge opening 10 of described raw material box 1 and cotton feeding curtain 11 The feed end 113 of the carding machine is arranged up and down, and the discharge end 114 of the cotton curtain 11 communicates with the opening roller 13 through the roller channel 123; the carding machine also includes a front horizontal pallet 61, a middle horizontal pallet 6 and a rear horizontal pallet Supporting plate 62, a forward gap 63 is provided between the discharge end 114 of the cotton feeding curt...

Embodiment 2

[0053] Basic content is the same as embodiment 1, the difference is:

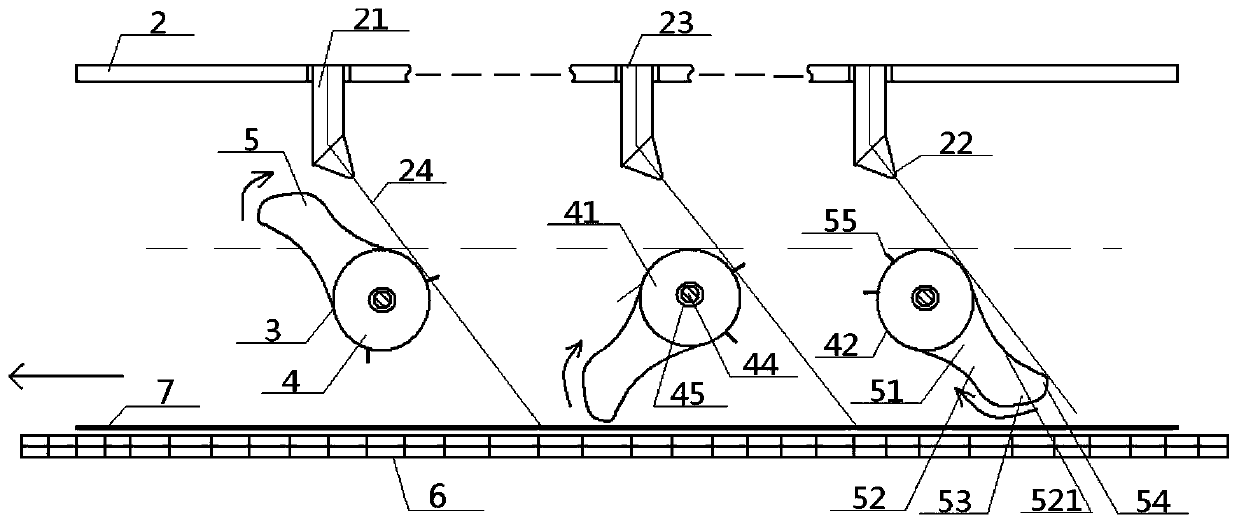

[0054] Structurally: the carding machine also includes a plurality of flow-regulating rotary spoons 3 arranged in sequence, the flow-regulating rotary spoons 3 and the air flow nozzles 21 are set up and down one by one, and the flow-regulating rotary spoons 3 are located between the air flow nozzles 21 and the middle horizontal support plate 6 The flow-adjusting rotating spoon 3 includes a fixed rotating cylinder 4 and a rotating concave spoon 5, and the fixed rotating cylinder 4 includes a column side wall 42 and a column top surface 41 connected to its two ends, a column bottom surface 43, and a column top surface 41, The same column shaft 44 runs through the middle of the column bottom surface 43. The rotary concave spoon 5 includes a connecting column part 51, a middle waist part 52 and an outer pressure part 53. The inner end of the connecting column part 51 and the column side circumference 42 Connect...

Embodiment 3

[0057] Basic content is the same as embodiment 1, the difference is:

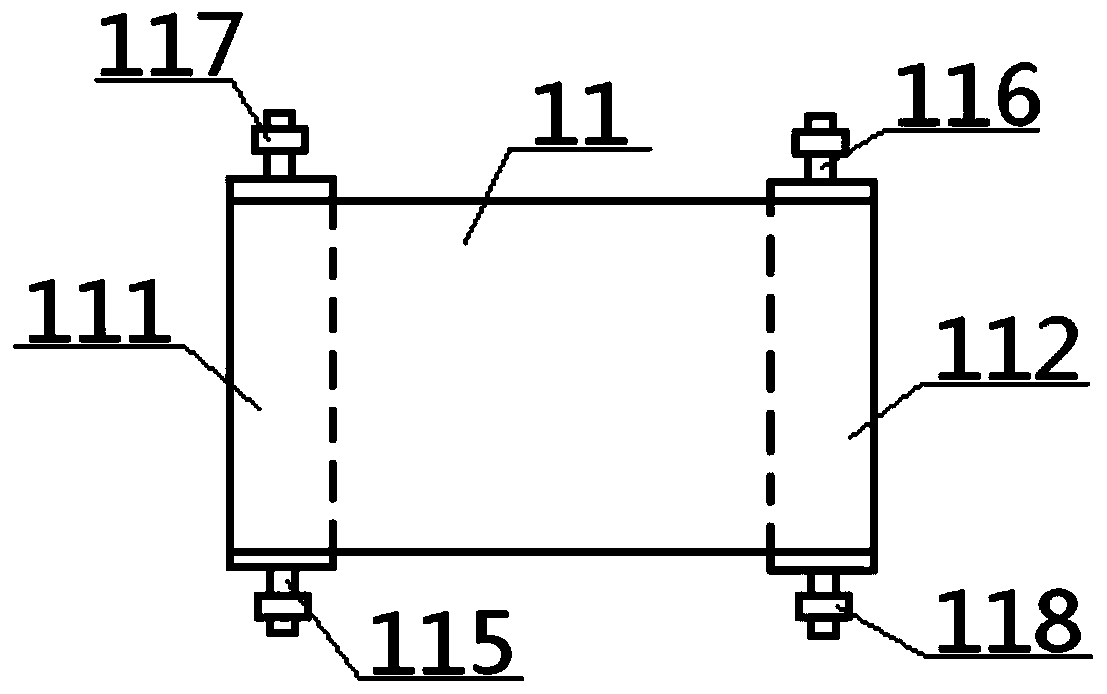

[0058] The bottom surface of the middle level supporting plate 6 is connected with the top of the water collection tube 68, and the bottom of the water collection tube 68 is connected with the output end of the cylinder motor 681; The bottom surface of the board 6 communicates with a water collecting chamber 682 , and the bottom surface of the water collecting cylinder 68 is provided with a drain hole 683 communicating with the water collecting chamber 682 . The middle part of described front curtain roller 111, rear curtain roller 112 is provided with front roller shaft 115, rear roller shaft 116 respectively, and the two ends of described front roller shaft 115 are respectively connected with the output end of a front roller motor 117, and described Both ends of the rear roller shaft 116 are respectively connected to the output end of a rear roller motor 118 . The bottom of the front horizontal supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com