An integrated equipment for the production of flame-retardant cloth

A technology of flame-retardant cloth and equipment, which is applied in the field of flame-retardant cloth production integrated equipment, can solve the problems of low ammonia utilization rate, ammonia gas endangering workers' health, and large floor area, so as to improve utilization rate and reduce land occupation The effect of reducing the area and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

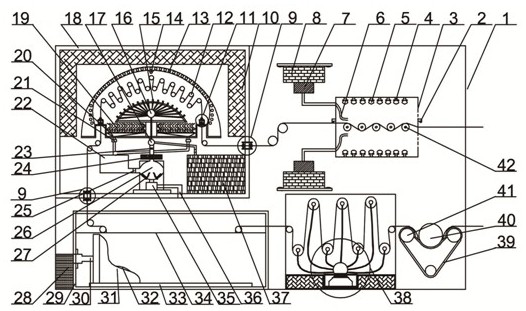

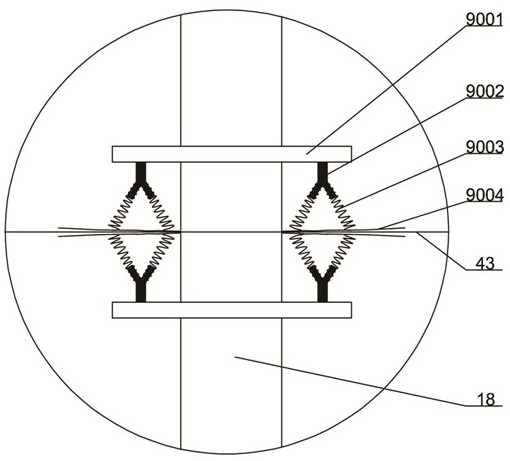

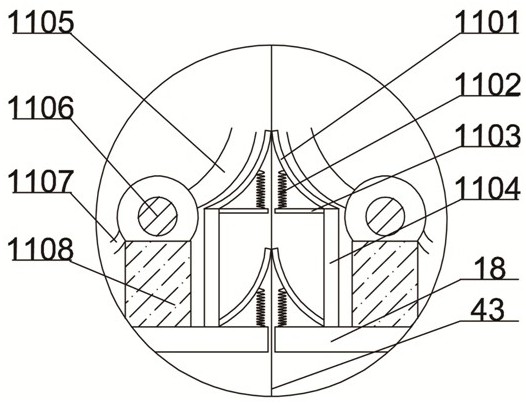

[0022] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: an integrated equipment for the production of flame-retardant cloth, including a preheating device, an ammonia fumigation device, an oxidation device, a drying device and a pre-shrinking device. On the lower side of the inner top plate of the body 1, the preheating device is provided with a preheating box 3, and a temperature and humidity meter 2 is installed in the middle of the left and right side panels of the preheating box 3, and an elbow 6 is provided on the left side panel of the preheating box 3, and the preheating box 3 There is a vent on the right side panel, the preheating box 3 is provided with a base 4 on the top and bottom plate, the base 4 is fixed with a heating lamp 5, the elbow 6 is connected to the first heating box 7, and the first heating box 7 is fixedly connected to the fan 8 , the flame-retardant cloth passes through the middle of the side panel of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com