A method and system for measuring air exchange capacity

A technology of air exchange and measurement method, which is applied in the field of nuclear safety and civil safety, and can solve the problems of not being able to meet the concentration balance of the constant injection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

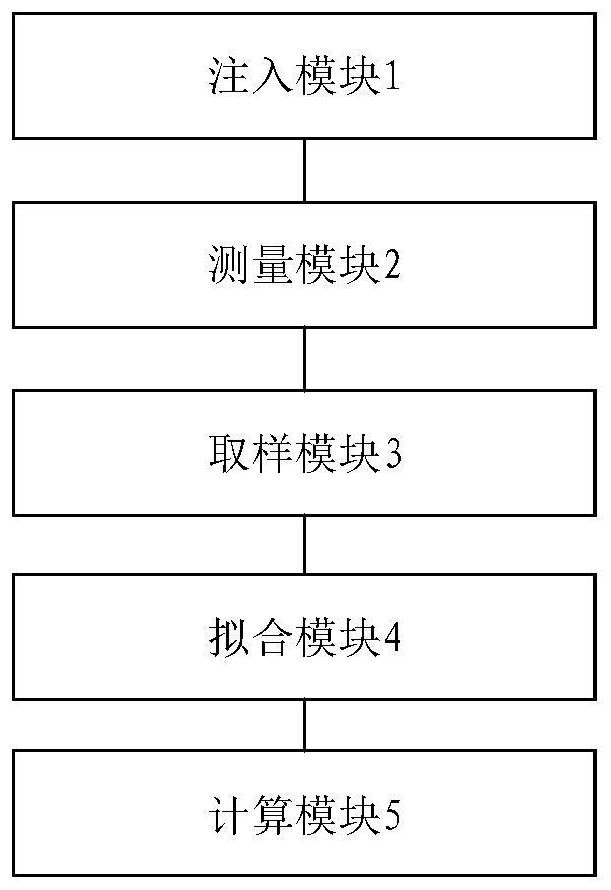

[0048] A method for measuring the air exchange rate provided by the present invention will be described in detail below.

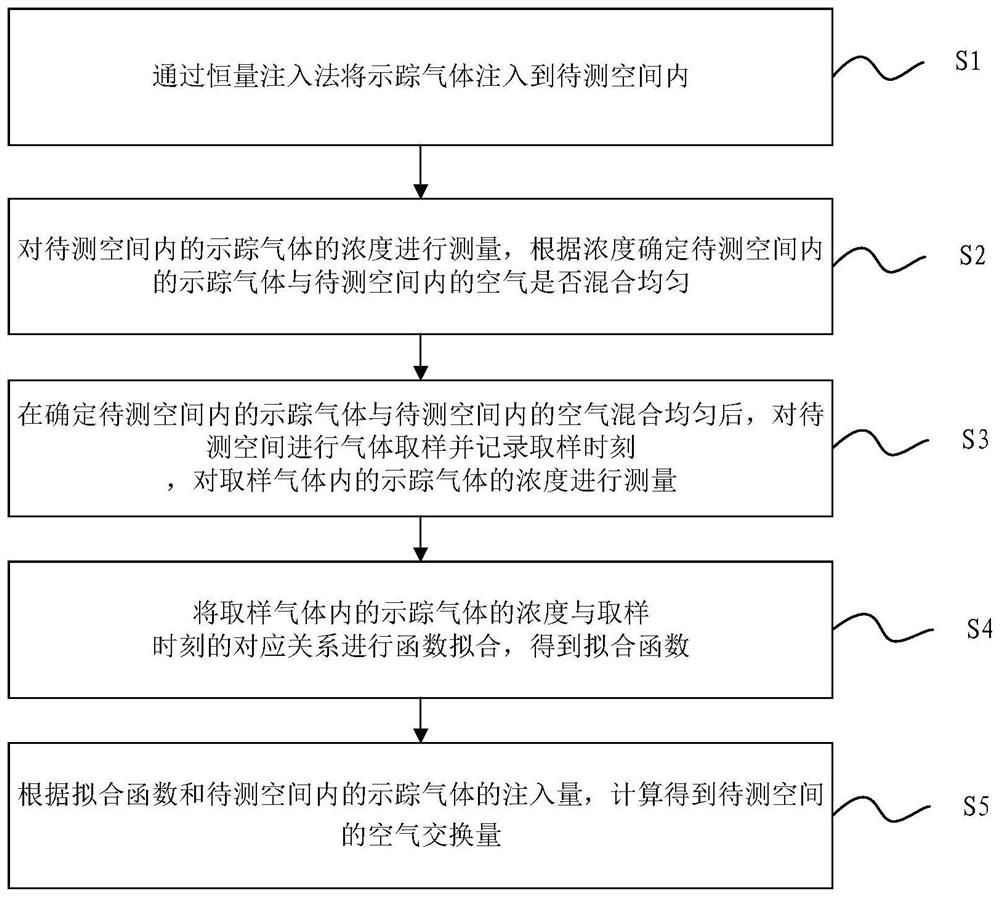

[0049] Such as figure 1 As shown, a measurement method of air exchange capacity, including:

[0050] S1. Inject the tracer gas into the space to be measured by the constant injection method;

[0051] S2. Measure the concentration of the tracer gas in the space to be measured, and determine whether the tracer gas in the space to be measured is mixed with the air in the space to be measured according to the concentration;

[0052] S3. After determining that the tracer gas in the space to be measured is uniformly mixed with the air in the space to be measured, perform gas sampling in the space to be measured and record the sampling time, and measure the concentration of the tracer gas in the sampled gas;

[0053] S4. Perform function fitting on the corresponding relationship between the concentration of the tracer gas in the sampling gas and the sampling ti...

Embodiment 2

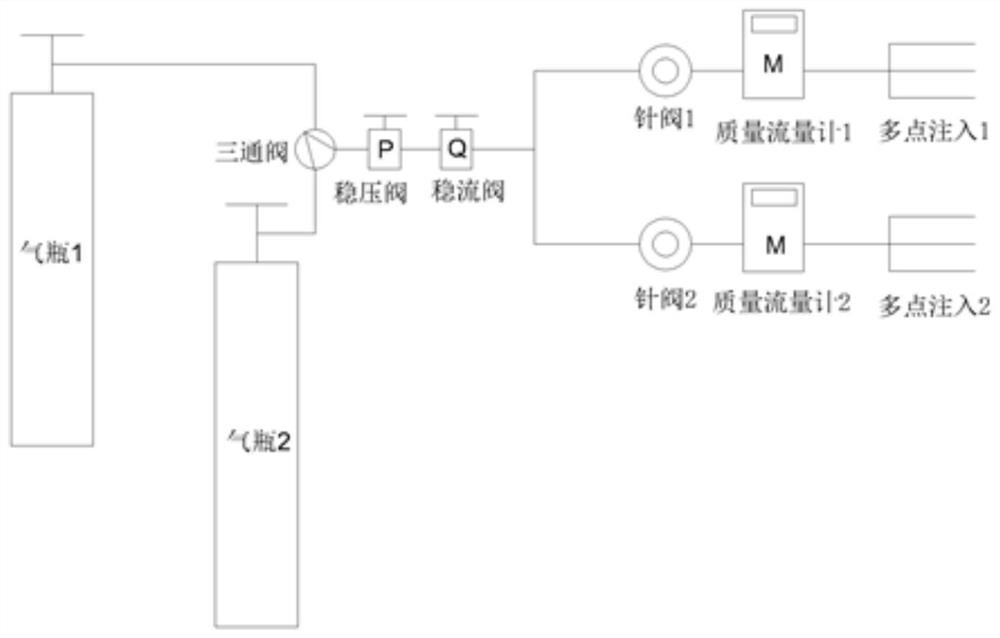

[0060] In step S1 of the first embodiment, the tracer gas can be injected into the air inlet pipe connected to the space to be measured through the tracer gas constant injection device. The specific structure of the tracer gas constant injection device is as follows.

[0061] Such as figure 2 As shown, the tracer gas constant injection device includes: two gas cylinders (gas cylinder 1, gas cylinder 2), three-way valve, pressure stabilizing valve, steady flow valve, two needle valves (needle valve 1, needle valve 2) , two mass flow meters (mass flow meter 1, mass flow meter 2) and two multi-point injection devices (multi-point injection 1, multi-point injection 2), in which the two gas cylinders are respectively connected to the two ports of the three-way valve The outlet of the three-way valve is connected to the inlet of the pressure stabilizing valve, the outlet of the pressure stabilizing valve is connected to the inlet of the stabilizing valve, the outlet of the stabili...

Embodiment 3

[0068] After step S5 of Embodiment 1, it also includes:

[0069] S6. Measure the fresh air volume in the space to be measured through the multi-point injection device and the multi-point sampling device to obtain the filtered fresh air volume;

[0070] S7. Subtract the filtered fresh air volume from the calculated air exchange volume of the space to be measured to obtain the volume of unfiltered air in the space to be measured.

[0071] Subtract the filtered fresh air volume from the calculated air exchange volume of the space to be tested to obtain the unfiltered air volume in the main control room of the nuclear power plant, which is the unfiltered air volume entering the main control room of the nuclear power plant. It contains radioactivity under accident conditions that have not been filtered and adsorbed by high-efficiency filters and iodine adsorbers, which is a key parameter related to the radiation safety of the personnel in the main control room.

[0072] The invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com