Measuring device for torque transmission between two shafts based on fiber grating and strain gauge technology

A fiber grating and measuring device technology, applied in measuring device, torque measurement, power measurement and other directions, can solve the problems of torsion bar deformation, poor versatility, torsion bar torsion break, etc., to improve the measurement accuracy and accuracy, and the structure is simple , the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

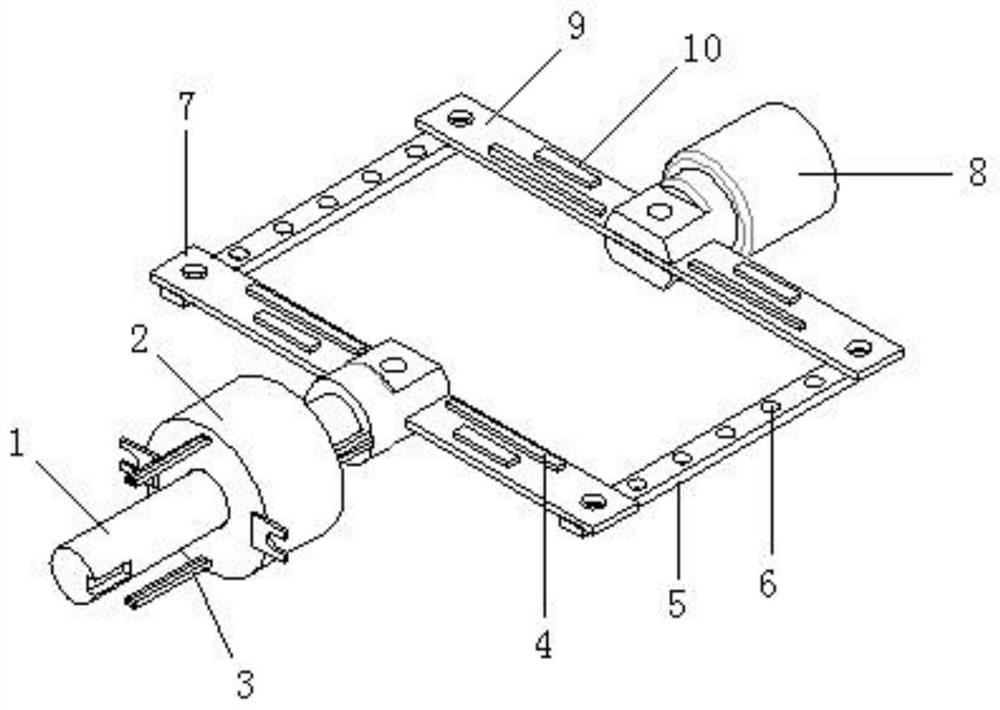

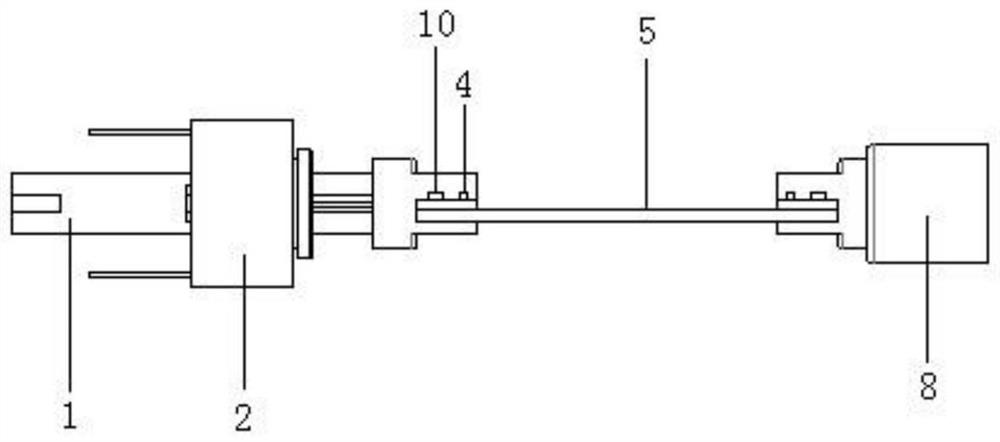

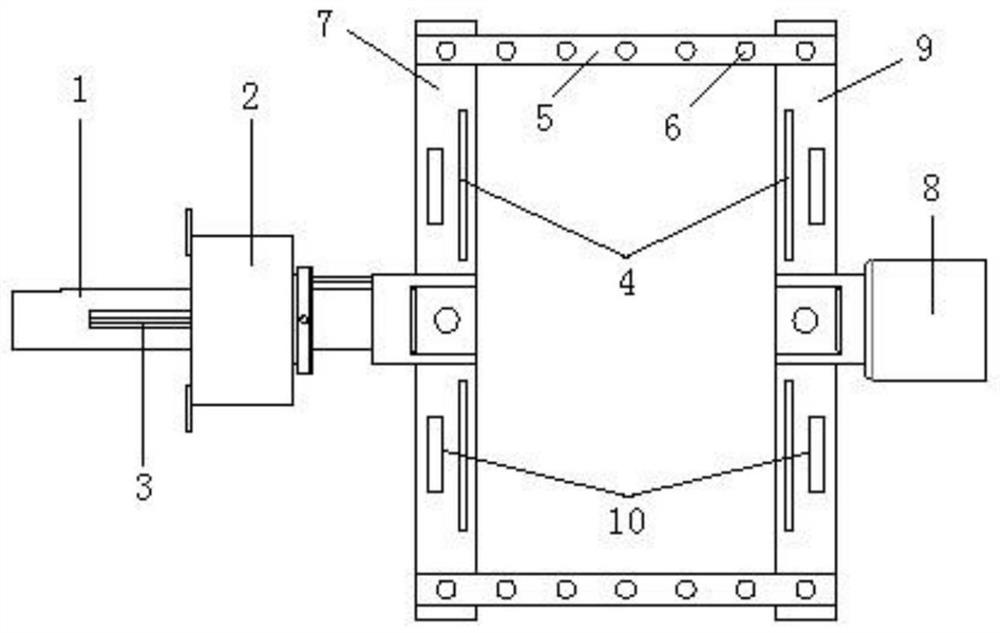

[0038] A two-axis torque transmission measurement device based on fiber Bragg grating and strain gauge technology, including two independent measurement modules of fiber Bragg grating and strain gauge, wherein: fiber Bragg gratings with different center wavelengths are glued to one side of the measuring device for common The four positions constitute the optical fiber grating measurement module, and the strain gauges are respectively glued to the four positions corresponding to the fiber grating on the other side of the measurement device to form the strain gauge measurement module. After calibration, the measurement device is assembled between the two axes that need to be measured. During the measurement process, two sets of independent signals of the fiber grating and the strain gauge are obtained. After signal processing and analysis, the magnitude of the torque transmitted between the two axes can be obtained.

[0039] like Figure 1-Figure 4 As shown, the first rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com