Analysis system and method for camera and projector calibration

An analysis system and projector technology, which is applied in the field of analysis systems, can solve problems such as image distortion, low model precision, and inconvenient calibration, and achieve the effect of high precision and model fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

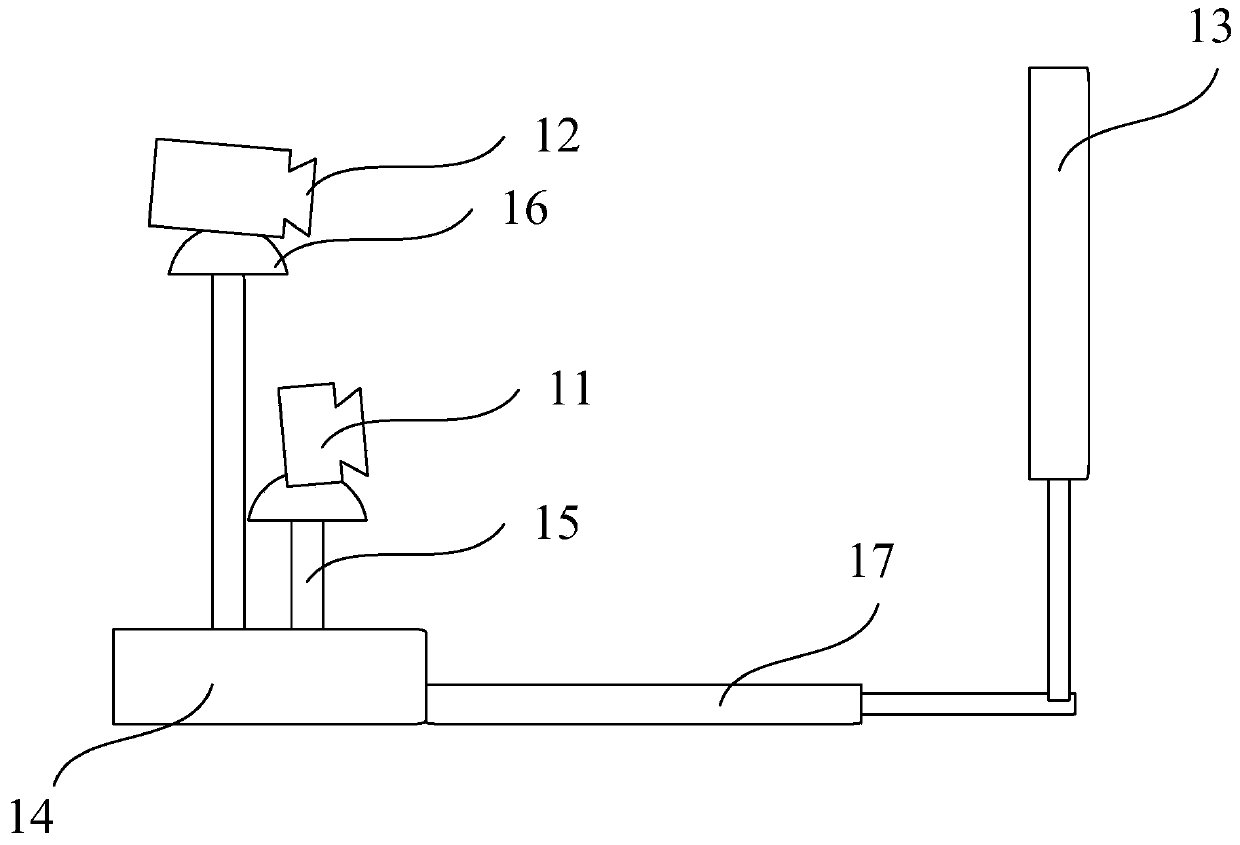

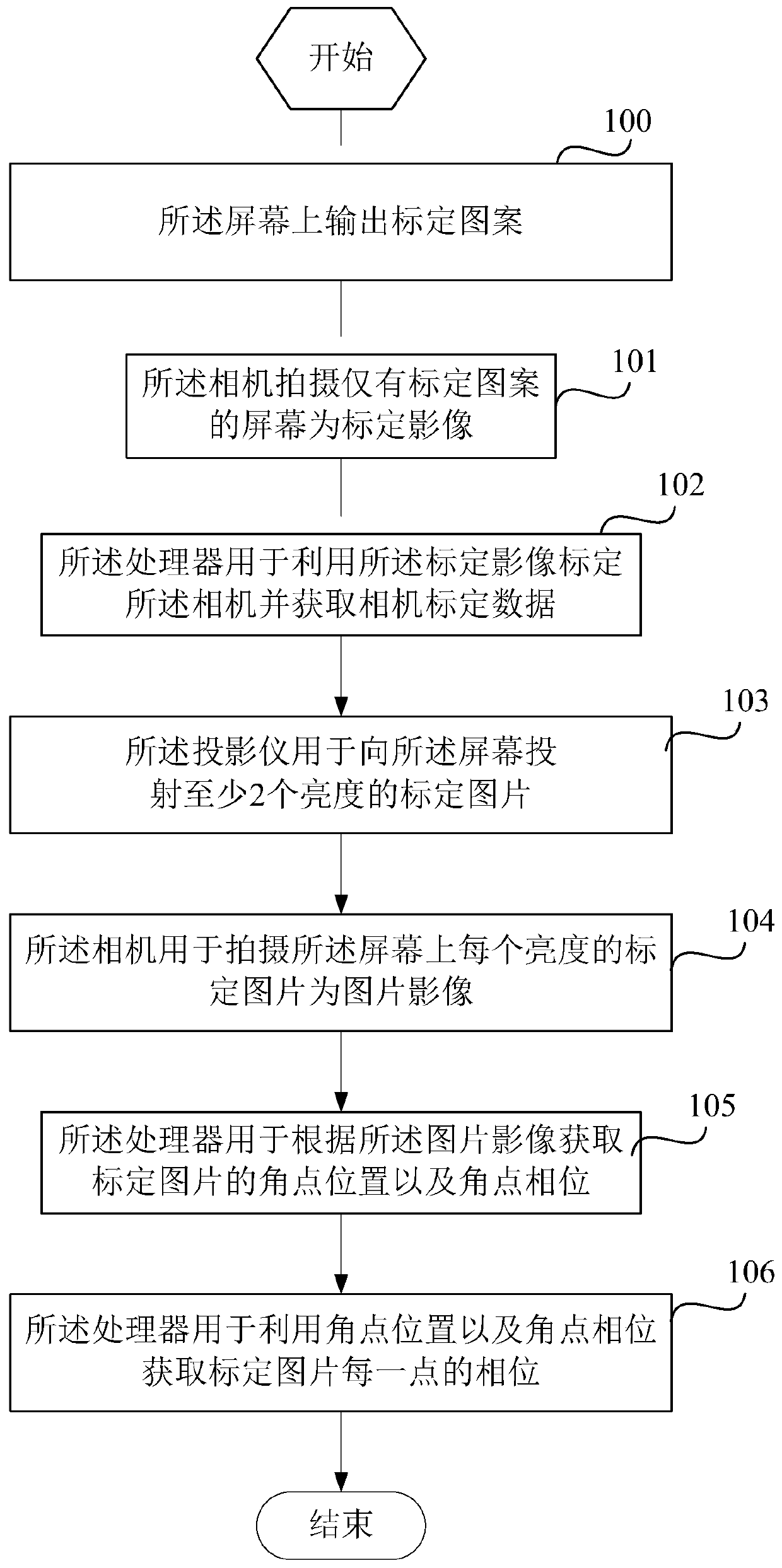

[0043] see figure 1 , the present embodiment provides an analysis system for calibrating cameras and projectors, the analysis system includes a camera 11, a projector 12, a screen 13 for projection, and a processor;

[0044] The processor is respectively connected to the camera and the projector, and the processor sends trigger signals to the camera and the projector respectively;

[0045] The camera includes a camera lens, the projector includes a projection lens, and the shooting direction of the camera lens and the projection direction of the projection lens are both aligned with the screen;

[0046] A calibration pattern is set on the screen;

[0047] The camera shoots a screen with only a calibration pattern as a calibration image;

[0048] The processor is configured to use the calibration image to calibrate the camera, and obtain camera calibration data;

[0049] The projector is used to project at least 2 brightness calibration pictures to the screen;

[0050] The ...

Embodiment 2

[0089] This embodiment is basically the same as Embodiment 1, the only difference is:

[0090] The screen includes a translucent whiteboard and a control chip. The calibration pattern is printed on the front of the translucent whiteboard, and several LED lights are arranged on the back of the translucent whiteboard. The lighting direction of the LED lights is aligned with the translucent whiteboard;

[0091] The control chip is used to control the brightness of the LED lamp;

[0092] The processor is further configured to send a trigger signal to the camera after sending a brightness adjustment signal to the control chip.

Embodiment 3

[0094] This embodiment is basically the same as Embodiment 1, the only difference is:

[0095] The screen is a liquid crystal screen, and the liquid crystal screen displays a preset pattern, the shape of the preset pattern is the same as that of the calibration pattern, and the color of the preset pattern is variable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com