Fabrication method of high-temperature superconduction ReBCO cable structure applied to CICC

A manufacturing method and high-temperature superconducting technology, applied in the field of cable manufacturing, can solve the problems of performance degradation, reducing the current density of CICC conductor engineering, and difficulty in the design and development of CICC superconducting cables, and achieve high current-carrying density and flexible bending characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

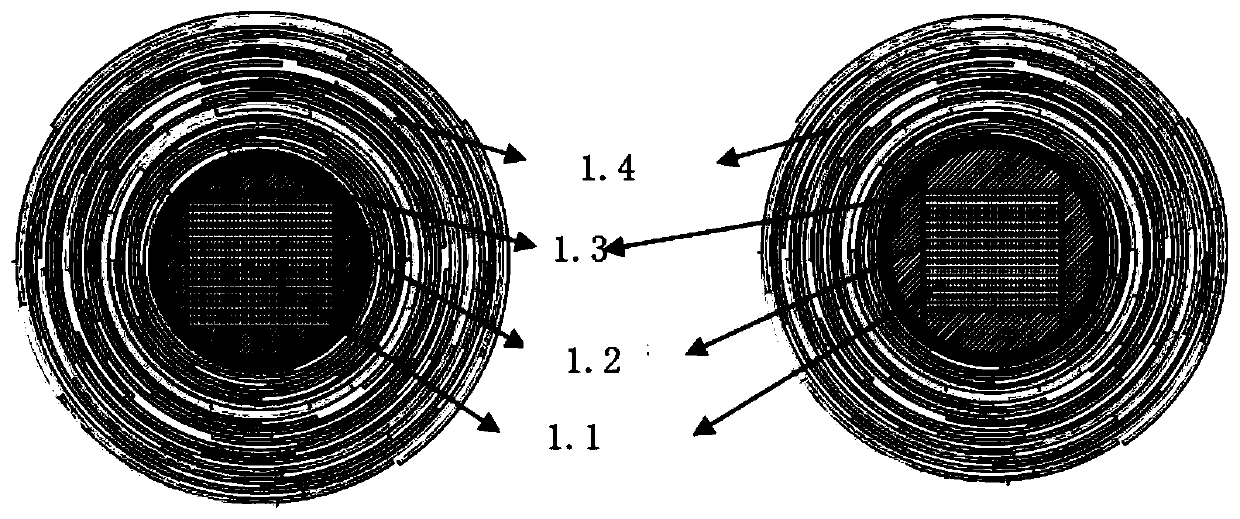

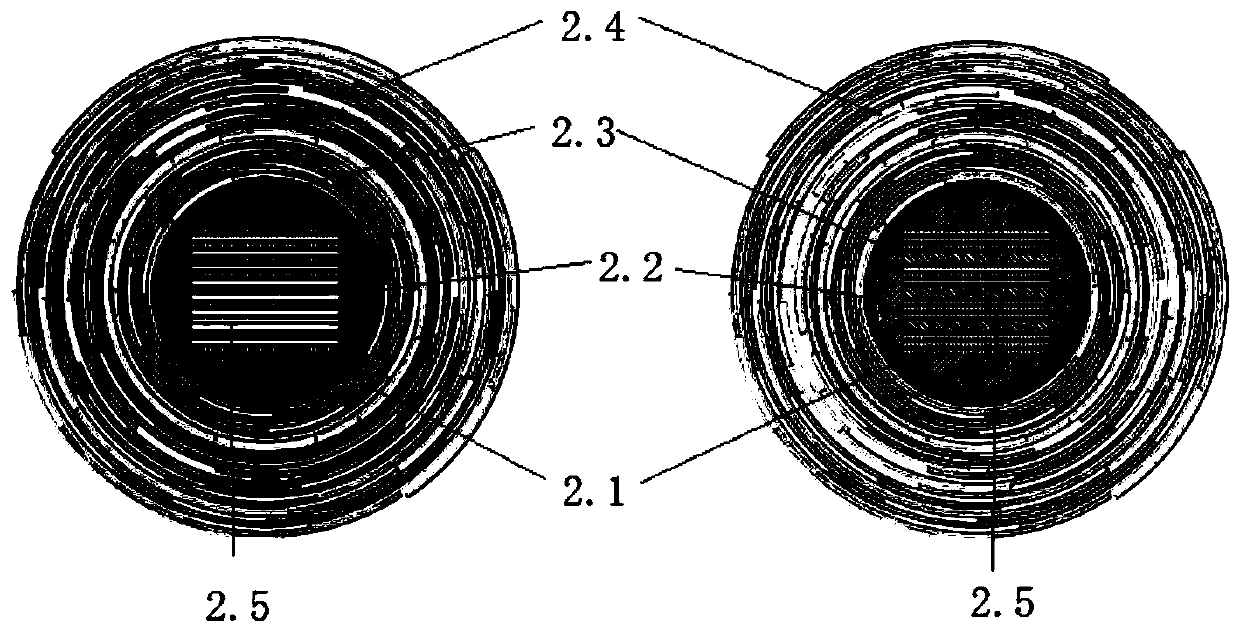

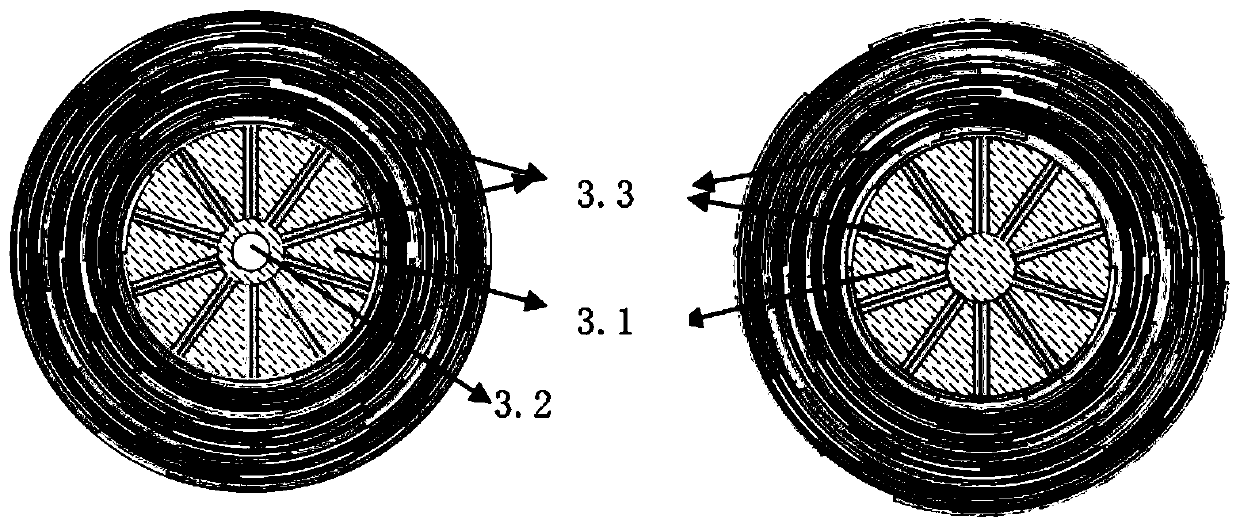

[0038] Such as Figure 1a As shown, a high-temperature superconducting ReBCO cable structure manufacturing method applied to CICC includes the following steps:

[0039](1) ReBCO superconducting tape 1.1 with a width of 1-6mm and a thickness of 0.05-0.1mm is used to superimpose a square structure;

[0040] (2) Fill the four sides of the square structure with arc-shaped filling strips 1.2 made of Cu / Al strips, making its periphery a circular structure, where the material and size of the arc-shaped filling strips can be determined according to the final cable space size and mechanical strength request to choose

[0041] (3) A single-layer or multi-layer Cu / Al wrapping tape 3 is spirally wound on the outside of the circular structure formed by the filling arc-shaped filling tape 1.2 to form a core body, and the outer diameter of the core body is between 1-20 mm;

[0042] (4) According to the current-carrying performance requirements, the ReBCO superconducting tape 1.4 is spirally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com