A multi-stage fine crushing type construction waste crusher

A construction waste and fine crushing technology, applied in grain processing and other directions, can solve the problems of low crushing efficiency, not easy to crush, hard construction waste, etc., and achieve good crushing effect, energy saving and economical improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

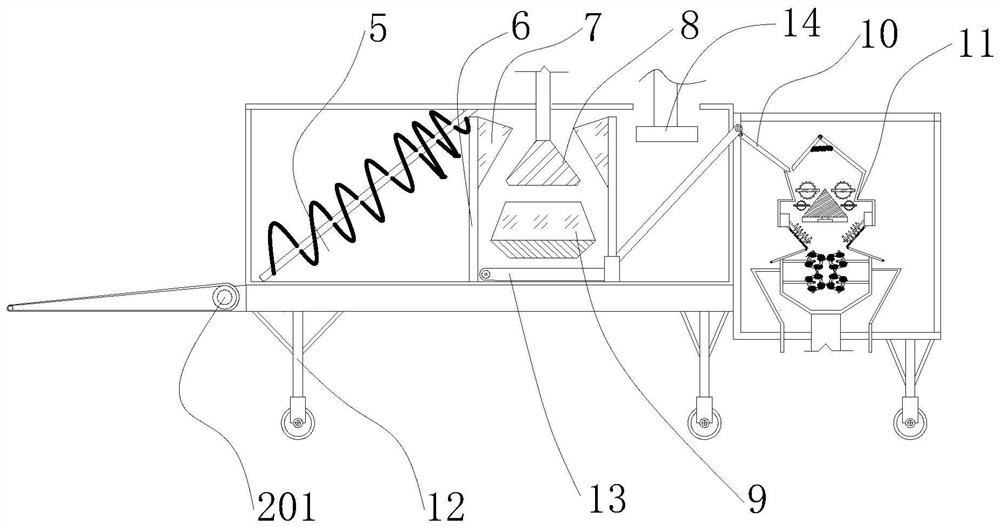

[0035] as attached figure 1 to attach Figure 7 Shown:

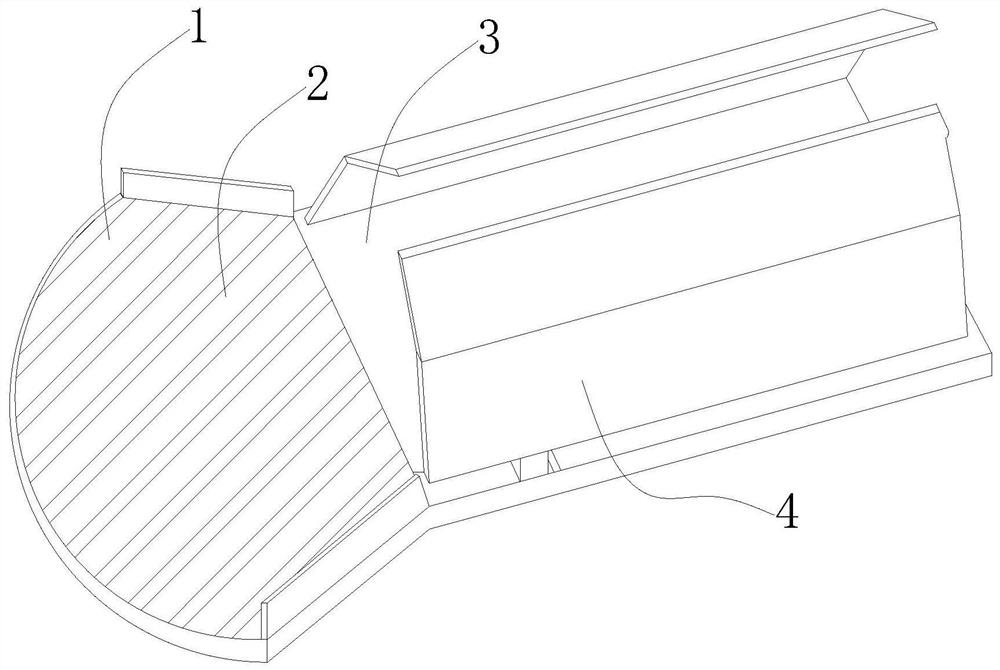

[0036] The present invention provides a multi-stage fine crushing construction waste crusher, which includes a feeding mechanism, a primary crushing mechanism, a fine crushing mechanism and a force-reducing and shock-absorbing baffle 4. The feeding mechanism includes a collecting and expanding shovel 1 and a conveyor chain belt 2, The conveyor chain belt 2 is embedded on the surface of the collecting and expanding shovel 1, and the drive motor 201 is movably connected to the conveyor chain belt 2;

[0037] The primary crushing mechanism includes a crushing chamber 3, a primary crushing chamber 6, a hammer 8 and a magnetic iron absorber 14. There is an opening above the crushing chamber 3, and both the hammer 8 and the magnetic iron absorber 14 run through the crushing chamber 3. The upper opening extends to the interior of the crushing chamber 3, and counter-attack blocks 7 are fixedly connected to both sides above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com