Lead screw and cooling system thereof

A technology of cooling system and screw rod, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. It can solve the problems of increasing the reverse gap and affecting the accuracy of the screw, so as to increase the contact area, Increased heat exchange efficiency and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through specific embodiments.

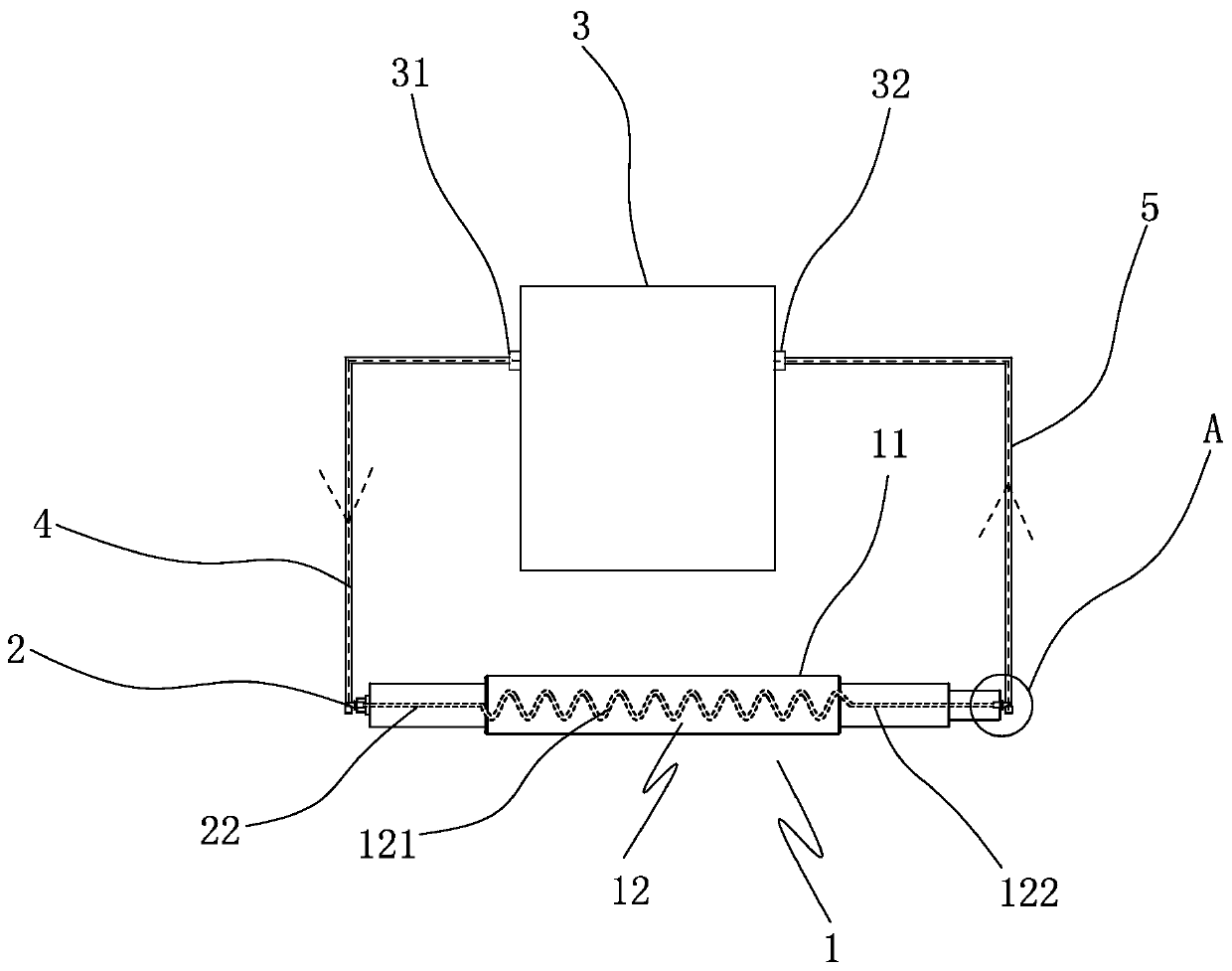

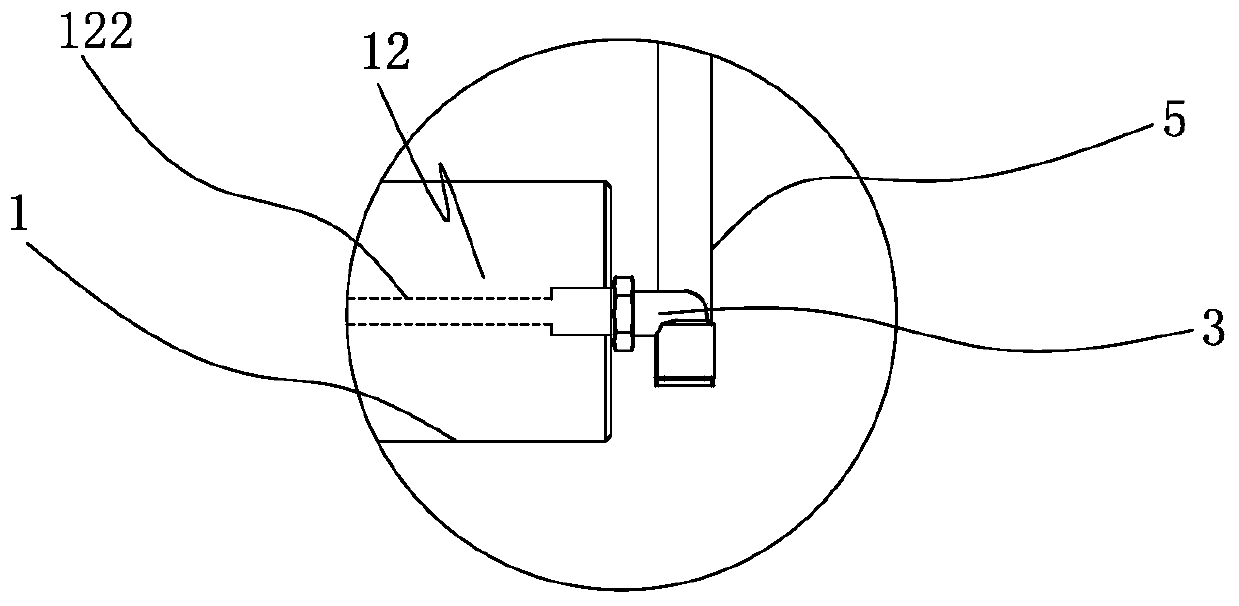

[0019] refer to Figure 1 to Figure 2 As shown, a cooling system for a screw rod includes a screw rod 1 , a cooling device 3 , a rotary joint 2 , an output pipeline 4 and an input pipeline 5 .

[0020] The screw rod 1 includes a screw rod body 11 and a spiral cooling tube 12 .

[0021] The spiral cooling pipe 12 is set in the screw body 11 by casting. Specifically, the spiral cooling pipe 12 is made of high-temperature-resistant copper tube. When the screw rod 1 is cast, the high-temperature-resistant spiral cooling pipe 12 is put into the mold, and then Pour molten steel to form a semi-finished product, and then process threads on the outer wall of the semi-finished product to form a screw 1. The spiral cooling tube 12 and the screw body 11 are cast in one casting process. The preparation process is simple, and the spiral cooling tube 12 will not be damaged by wire The high-speed ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com