Vibration damper and arrangement in fiber web machine

A fiber web machine and shock absorber technology, which is applied to shock absorbers, friction shock absorbers, shock absorbers, etc. The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

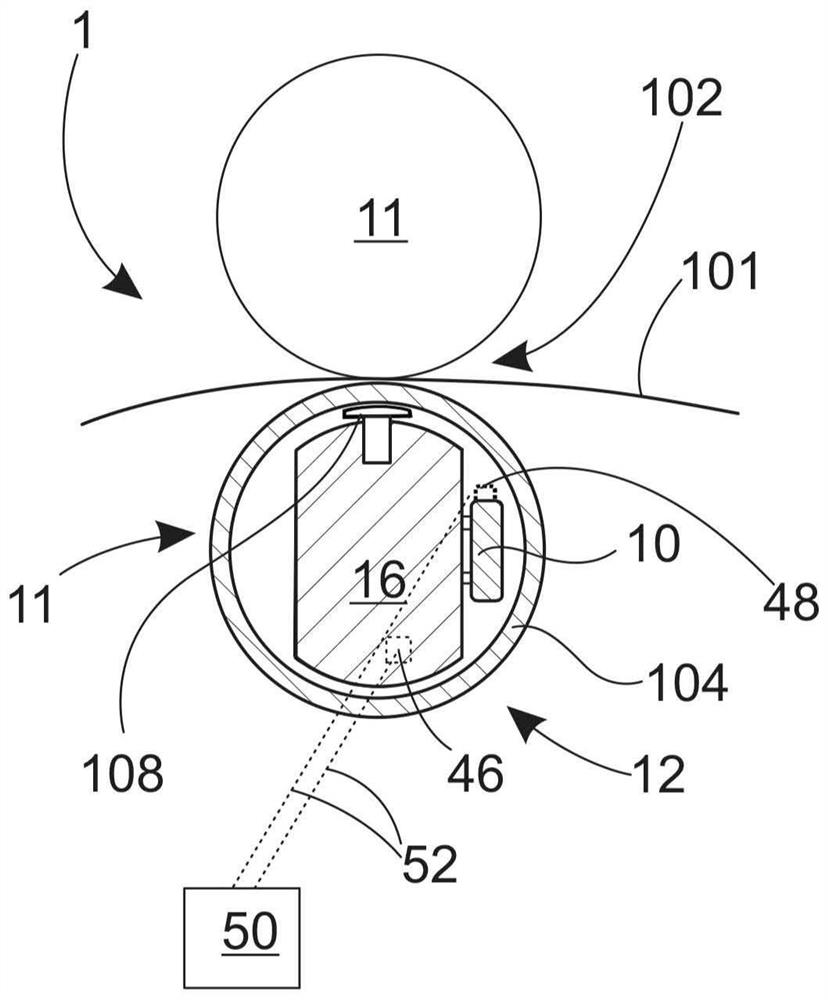

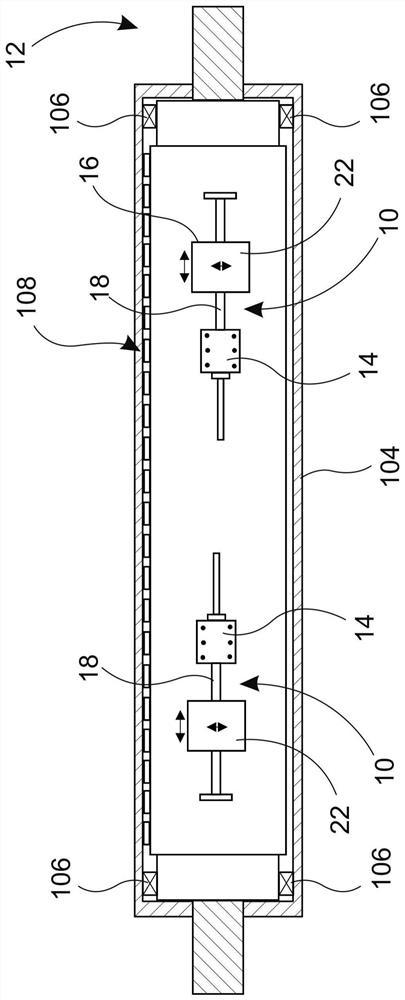

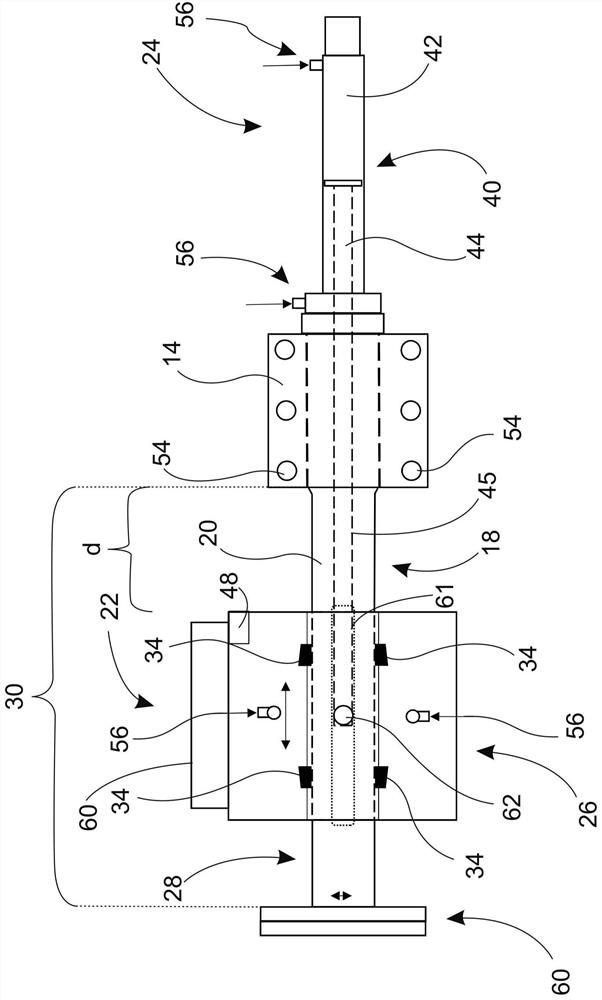

[0042]Figure 1 - Figure 6A first preferred embodiment of the arrangement and damper according to the present invention is shown. The second possible implementation is explained in the final explanation of the specification.

[0043]According to the arrangement 1 of the present invention, it is advantageously adapted to the fiber web machine, in which the compression zone 102 formed by the two roller 11 is preferably a press-press according to the pressing portion of the press or the most preferred. It is the pressure zone of the concurrent machine. The control of the vibration of the roller to form the pressure zone is particularly important, since there is no modified device phase for the non-uniform fiber web after the concurrent machine. Further, the deflection compensation roller on the capping machine is coated with a soft cover for optimizing the surface characteristics of the paper, where the deflection compensation roller is particularly sensitive to the vibration due to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com