Polarization and band gap adjustable ferroelectric photovoltaic film and preparation method thereof

A ferroelectric photovoltaic and ferroelectric technology, applied in the direction of photovoltaic power generation, sustainable manufacturing/processing, circuits, etc., can solve the problems of low operating absorption coefficient, large optical band gap, obstruction, etc., and achieve low cost, high uniform quality, The effect of simple film making equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

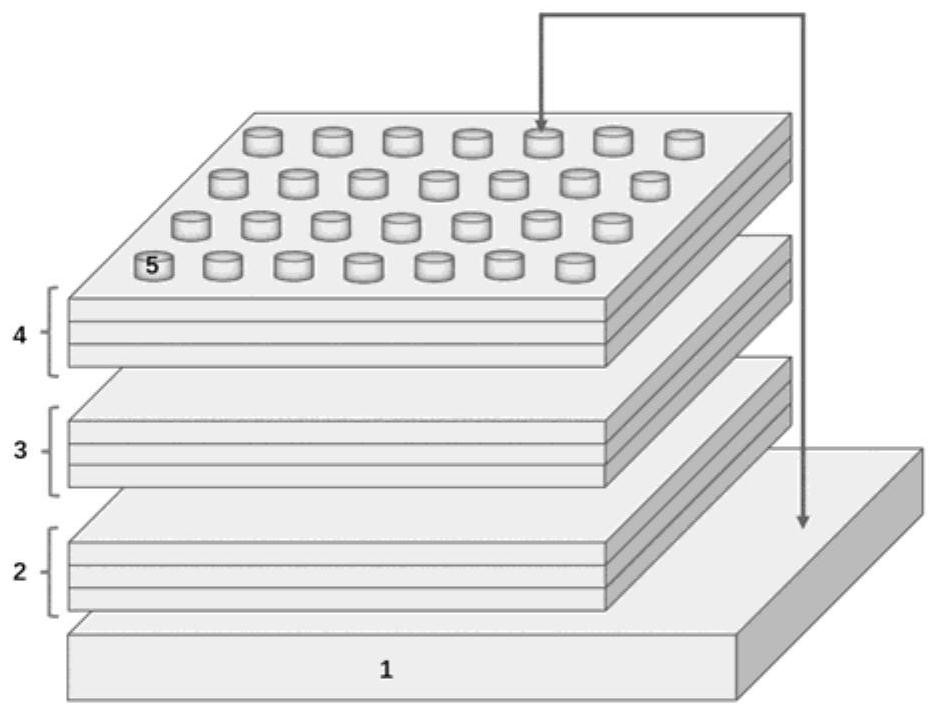

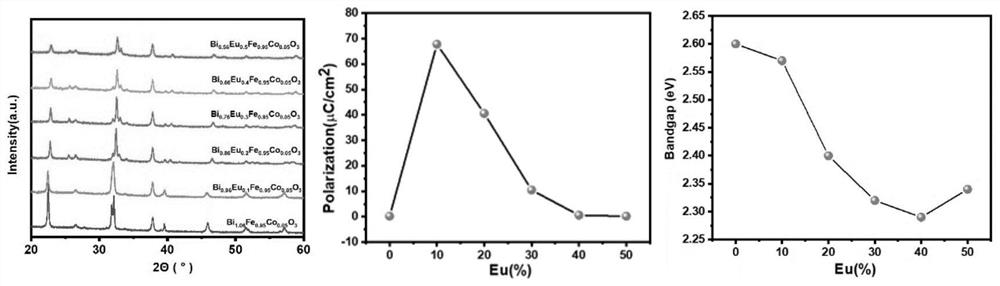

[0071] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O) was added 4.8 mL ethylene glycol methyl ether (EGME). Then add cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) and ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O). Formulated as Bi 1.06 Fe 0.95 co 0.05 o 3 、 Bi 0.96 Eu 0.1 Fe 0.95 co 0.05 o 3 、 Bi 0.86 Eu 0.2 Fe 0.95 co 0.05 o 3 、 Bi 0.76 Eu 0.3 Fe 0.95 co 0.05 o 3 、 Bi 0.66 Eu 0.4 Fe 0.95 co 0.05 o 3 and Bi 0.56 Eu 0.5 Fe 0.95 co 0.05 o 3 And the precursor solution with a molar concentration of 0.2M was 5 mL. Spin-coat the film on the FTO substrate, use a pipette gun to absorb an appropriate amount of precursor solution and add it drop by drop on the substrate to fully cover the surface of the substrate, first use 500rpm slow spin coating for 15s, and then use 4000rpm fast spin coating for 20s; Pyrolysis on a heating plate at 350°C for 10 minutes, air-cooled to room tempera...

Embodiment 2

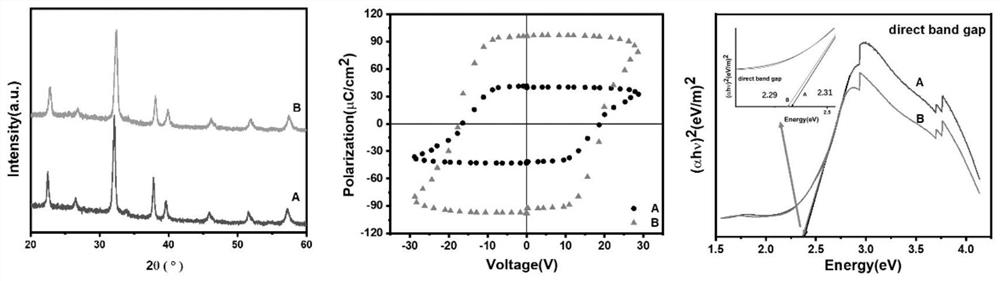

[0074] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O) was added 4.8 mL ethylene glycol methyl ether (EGME). Then add cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) and ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O). Formulated as Bi 0.96 Eu 0.1 Fe 0.95 co 0.05 o 3 and Bi 0.86 Eu 0.2 Fe 0.95 co 0.05 o 3 And the precursor solution with a molar concentration of 0.2M was 5 mL. Spin-coat the thin film on the FTO substrate, first use a pipette gun to absorb an appropriate amount of Bi 0.96 Eu 0.1 Fe 0.95 co 0.05 o 3 Add dropwise on the substrate to fully cover the surface of the substrate, use 500rpm slow spin coating for 15s and then 4000rpm fast spin coating for 20s; move the substrate to a heating plate at 350°C for 10min, air cool to room temperature, and repeat 3 layers; Then move it into the annealing furnace to raise the temperature rapidly, and anneal at 650°C for 30 minutes; cool it to ...

Embodiment 3

[0079] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O) was added 4.8 mL ethylene glycol methyl ether (EGME). Then add cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) and ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O). Formulated as Bi 0.96 Eu 0.1 Fe 0.95 co 0.05 o 3 and Bi 0.86 Eu 0.2 Fe 0.95 co 0.05 o 3 And the precursor solution with a molar concentration of 0.2M was 5 mL. Spin-coat the thin film on the FTO substrate, first use a pipette gun to absorb an appropriate amount of Bi 0.96 Eu 0.1 Fe 0.95 co 0.05 o 3 Add dropwise on the substrate to fully cover the surface of the substrate, use 500rpm slow spin coating for 15s and then 4000rpm fast spin coating for 20s; move the substrate to a heating plate at 350°C for 10 minutes; air cool to room temperature, repeat 3 layers Move it into an annealing furnace to rapidly raise the temperature, and anneal at 650°C for 30 minutes; cool in air to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com