Method for forming lithium ion battery and lithium ion battery

A lithium-ion battery and lithium salt technology, which is applied in the direction of secondary battery charging/discharging, secondary battery, secondary battery repair/maintenance, etc. Solvent decomposition potential is difficult to find, formation time and temperature are difficult to match, etc., to achieve the effect of reducing lithium ion consumption, precise and controllable composition, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

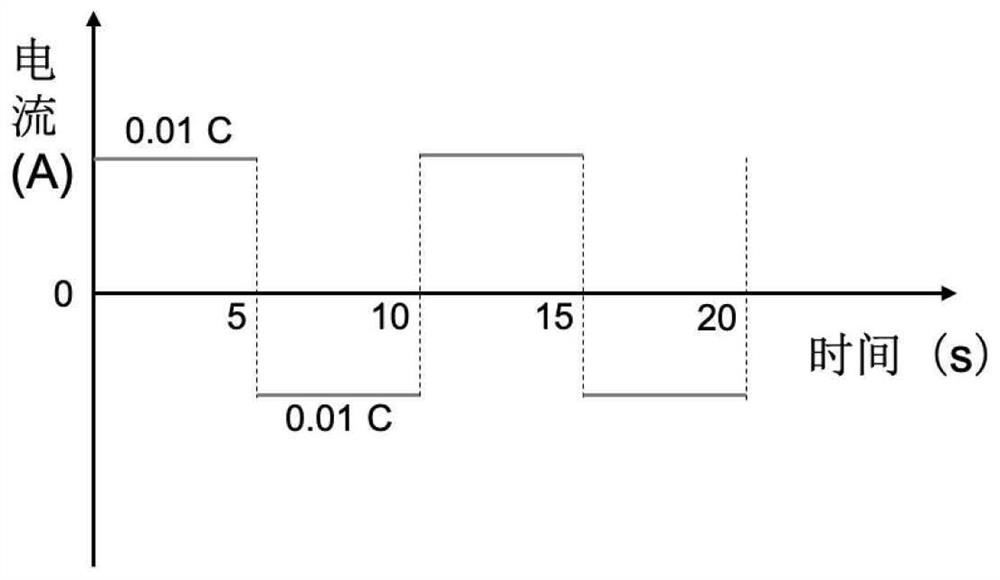

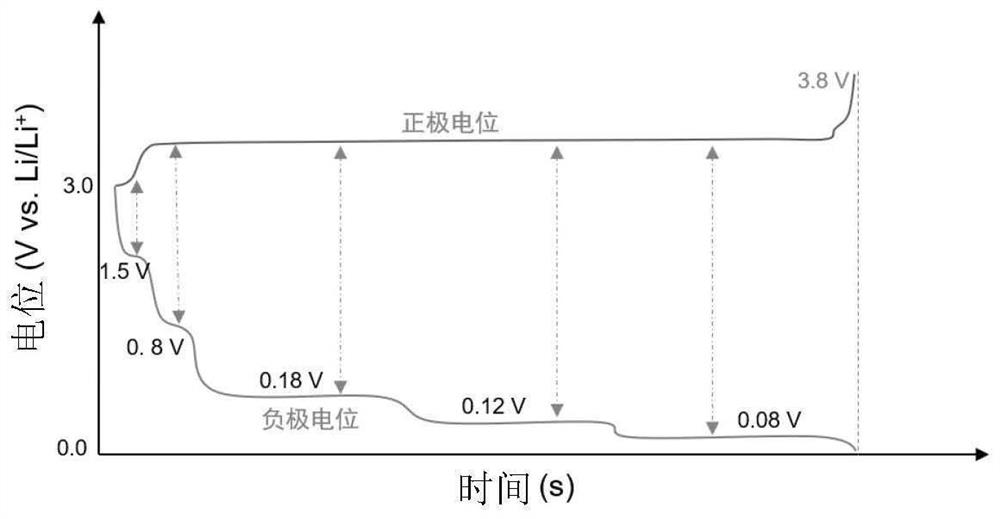

[0114] After the lithium-ion battery is filled and sealed: (1) stand at a high temperature of 40°C for 1.0h; (2) charge at a constant voltage of 1.2V at a low temperature of -10°C for 0.5h; (3) charge at a temperature of -10°C Charge at a low temperature with a pulse current of 0.01C for 0.1s, and the number of pulses is 2 times; (4) charge at a low temperature of -10°C with a constant voltage of 2.2V for 0.5h; (5) stand at a high temperature of 40°C for 1.0h ; (6) Exhaust the generated gas with a vacuum degree of 0.1MPa, and the exhaust time is 3s, and repackage the battery.

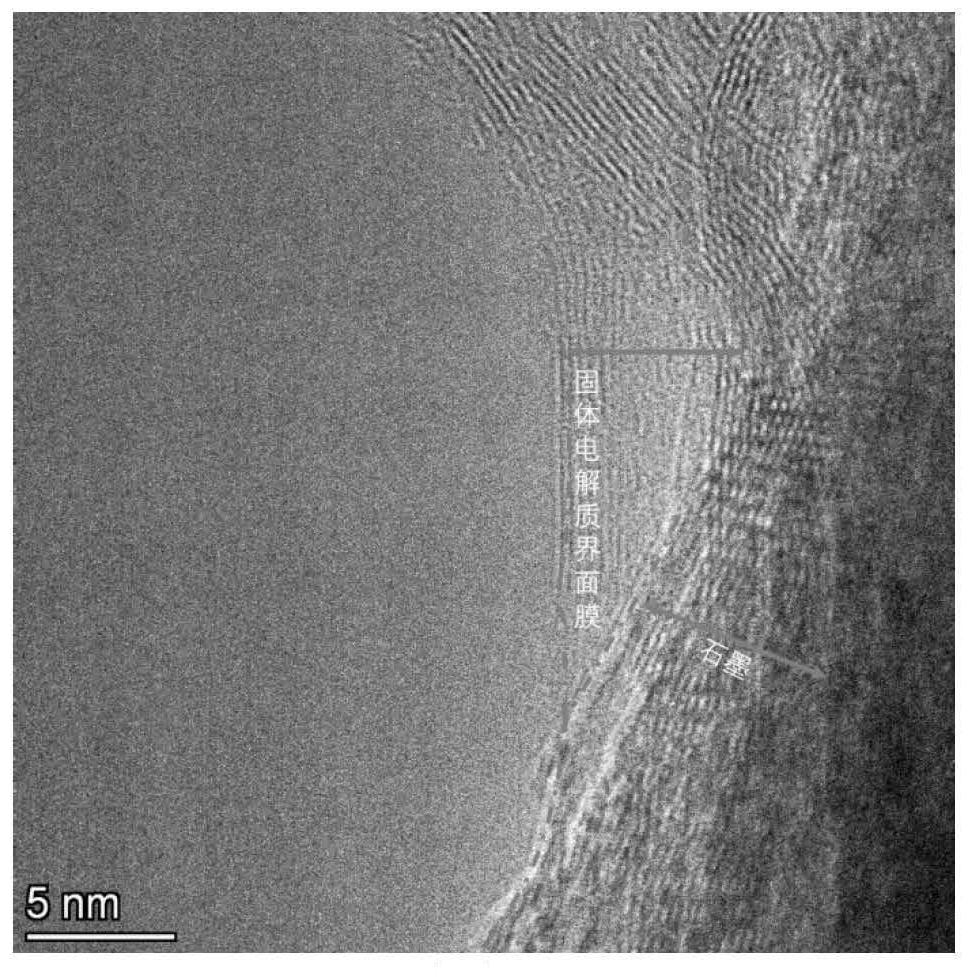

[0115] Among them, the lithium-ion battery is a full battery with a lithium iron phosphate positive electrode matched with a graphite negative electrode; the negative electrode solid electrolyte interface film obtained after formation presents an organic-inorganic interwoven structure.

Embodiment 2

[0117] After the lithium-ion battery is filled and sealed: (1) stand still at a high temperature of 55°C for 5.0h; (2) charge at a constant voltage of 1.8V at a low temperature of 0°C for 48h; (3) charge at a low temperature of 0°C with Charge with a pulse current of 0.1C for 10s, and the number of pulses is 10 times; (4) charge with a constant voltage of 3.0V at a low temperature of 0°C for 48h; (5) stand at a high temperature of 60°C for 5.0h; (6) charge with a constant voltage of 0.8 The vacuum degree of MPa exhausts the generated gas, and the exhaust time is 20s, and the battery is repackaged.

[0118] Among them, the lithium-ion battery is a full battery with a lithium iron phosphate positive electrode matched with a silicon-carbon negative electrode; the negative electrode solid electrolyte interface film obtained after formation presents an organic-inorganic interwoven structure.

Embodiment 3

[0120] After the lithium-ion battery is filled and sealed: (1) stand at a high temperature of 45°C for 2.5 hours; (2) charge at a constant voltage of 1.6V at a low temperature of -5°C for 2 hours; (3) charge at a low temperature of -5°C Charge for 5s with a pulse current of 0.05C, and the number of pulses is 4 times; (4) charge with a constant voltage of 2.6V at a low temperature of -5°C for 24h; (5) stand at a high temperature of 50°C for 24.0h; (6) ) Exhaust the generated gas with a vacuum of 0.3MPa, the exhaust time is 5s, and repackage the battery.

[0121] Among them, the lithium-ion battery is a full battery with a lithium iron phosphate positive electrode matched with a lithium-carbon negative electrode; the negative electrode solid electrolyte interface film obtained after formation presents an organic-inorganic layered structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com