A method for synthesizing intrinsic magnetic topological insulators

A topological insulator and magnetic technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as difficult, tedious and complicated growth process, slow growth process, etc., to achieve accurate and controllable layer number, thin film single Good crystallinity, precise and controllable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method for the synthesis intrinsic magnetic topological insulator of the present embodiment comprises the following steps: S1. substrate is placed in MBE vacuum chamber to remove water vapor and organic matter; S2. substrate, Mn evaporation source, Bi evaporation source, Te evaporation source Preheating to the target temperature; S3. Growing crystals on the substrate by molecular beam epitaxy co-deposition technology.

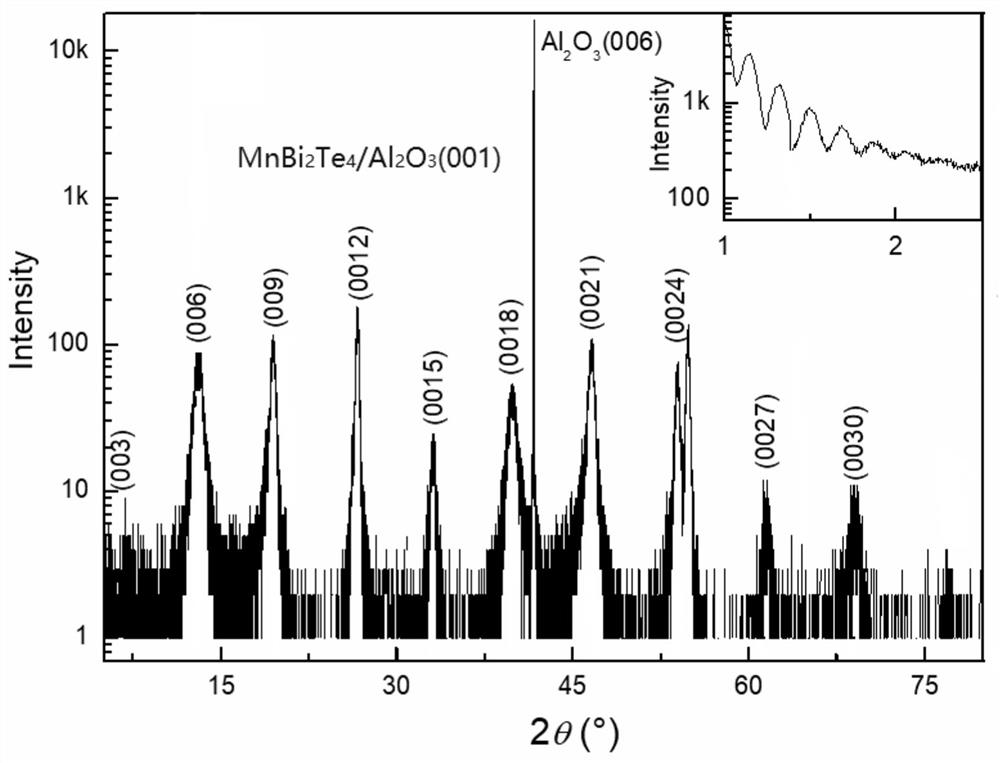

[0036] In this embodiment, the preferred substrate is Al 2 o 3 substrate; step S1 specifically includes: Al 2 o 3 The substrate is placed in the MBE vacuum chamber whose air pressure is lower than the first preset air pressure, heated to the first preset temperature range, and degassed until the air pressure in the MBE vacuum chamber returns to be lower than the first preset air pressure; the first The preset air pressure is 2.0×10 -10 mBar; the first preset temperature range is 600°C-800°C.

[0037] In this embodiment, further preferably, step ...

Embodiment 2

[0044] The method for the synthesis intrinsic magnetic topological insulator of the present embodiment comprises the following steps: S1. substrate is placed in MBE vacuum chamber to remove water vapor and organic matter; S2. substrate, Mn evaporation source, Bi evaporation source, Te evaporation source Preheating to the target temperature; S3. Growing crystals on the substrate by molecular beam epitaxy co-deposition technology.

[0045] In this embodiment, the preferred substrate is a Si substrate; step S1 specifically includes: S1.1 placing the Si substrate in an MBE vacuum chamber whose air pressure is lower than the second preset air pressure, and directly heating to the sixth preset temperature range , and degas until the air pressure in the MBE vacuum chamber returns to be lower than the second preset air pressure; the second preset air pressure is 2.0×10 -10 mBar; the sixth preset temperature range is 450°C-600°C; S1.2 Heat the Si substrate to the preset seventh tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com