Waterproof composite roof supported by steel structure and decorated by honeycomb aluminum plates and construction method of waterproof composite roof

A technology of honeycomb aluminum panels and composite roofs, which is applied to roof cladding, building roofs, and roof insulation materials. The effect of stability and strong wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

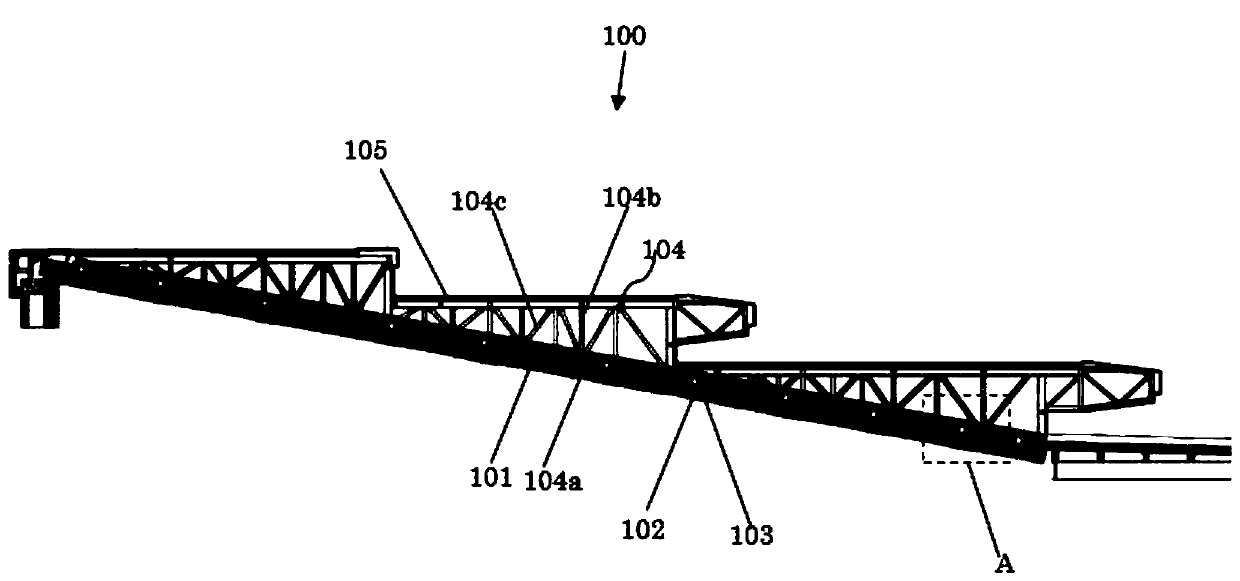

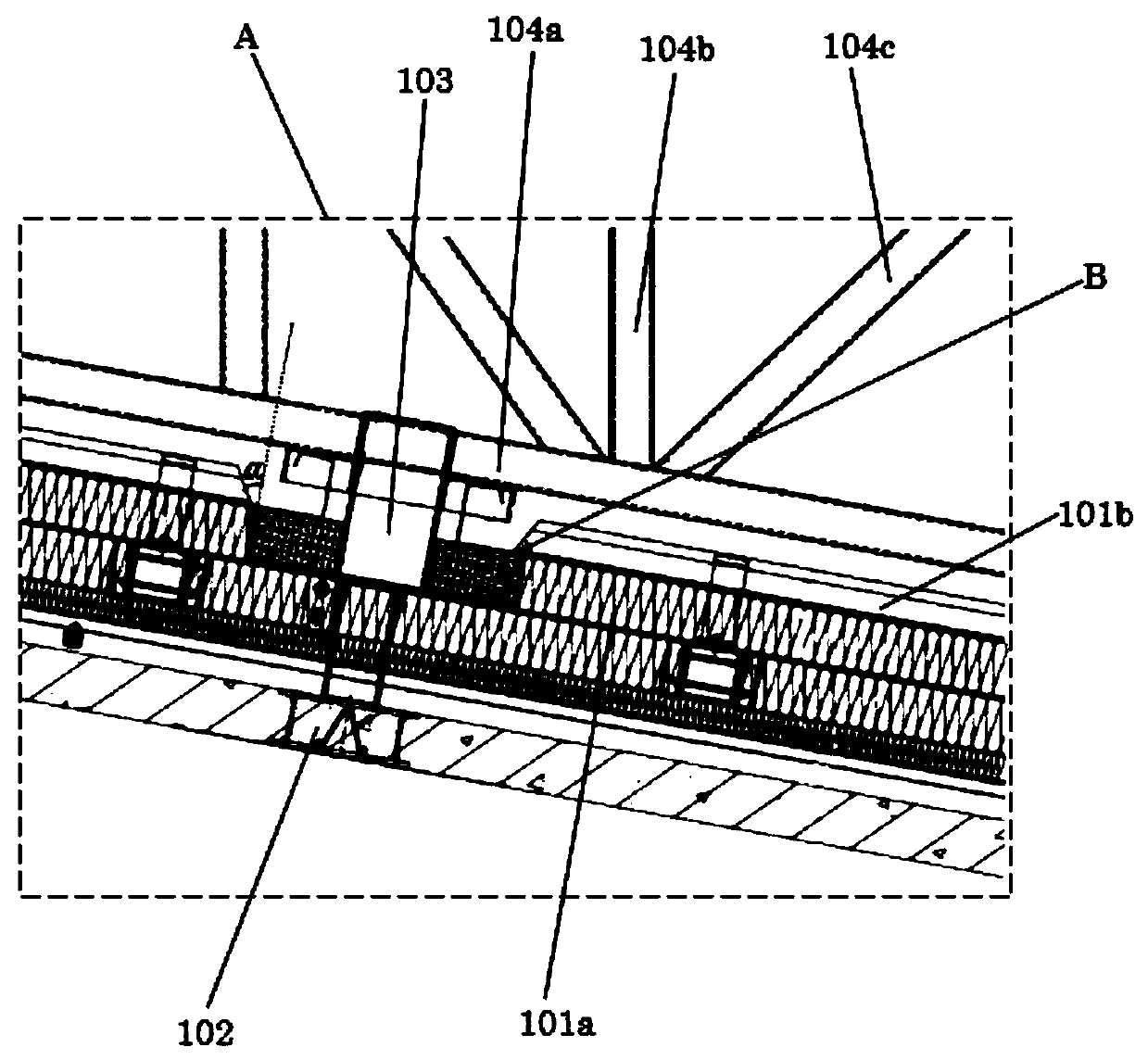

[0022] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following embodiments will specifically describe the waterproof composite roof of the present invention with steel frame support and honeycomb aluminum panel decoration and construction methods in conjunction with the accompanying drawings.

[0023] A construction method of waterproof composite roof with steel structure support and honeycomb aluminum plate decoration includes the following steps:

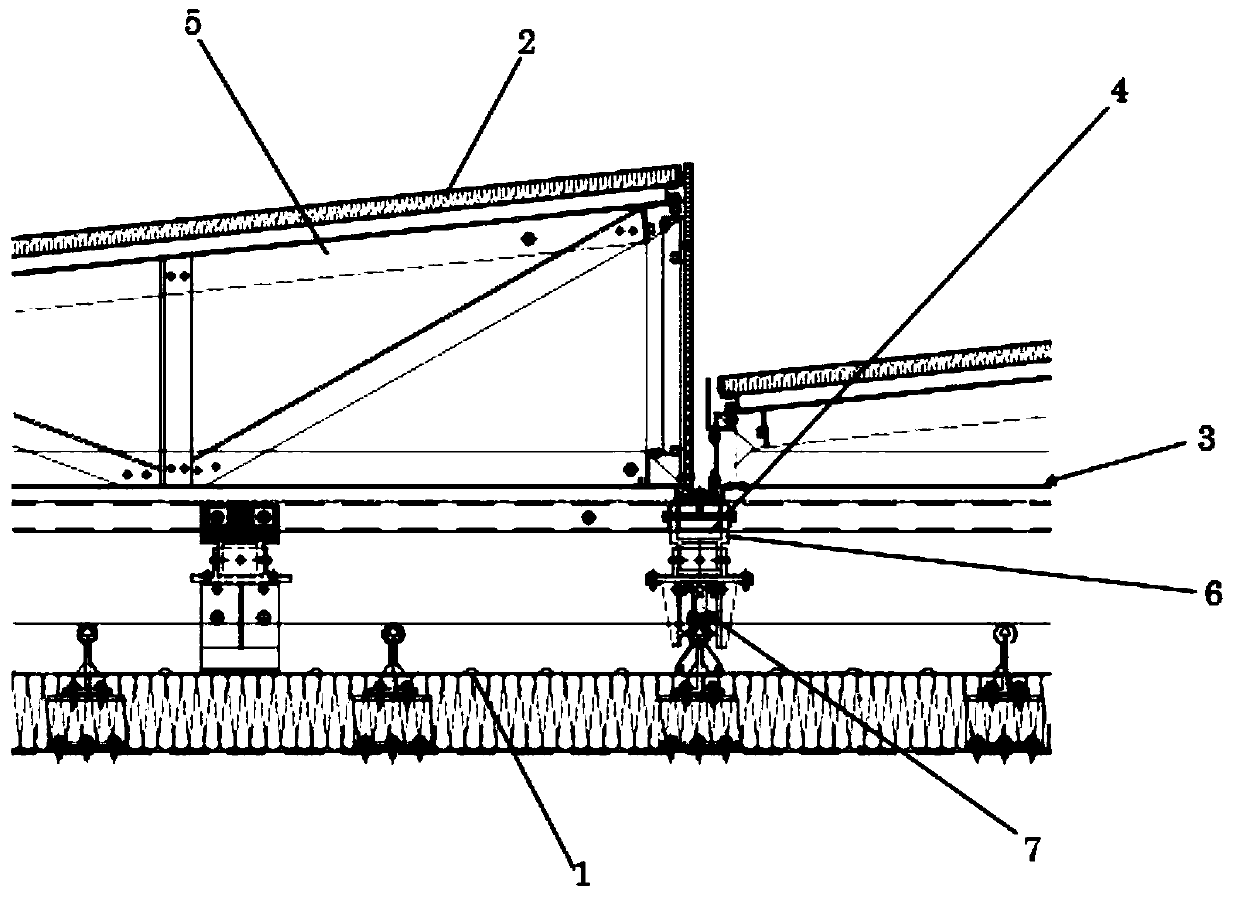

[0024] Step 1: Vertical seam waterproof metal roof opening

[0025] Multiple openings are opened on the already laid upright seam waterproof metal roof. The opening positions correspond to multiple embedded parts. The openings are 500×500 square openings. The surface of the openings is smooth and free of jaggedness and deformation. The position of the rib of the hole is cut to form an inclination angle of 10°~15° outward (such as image 3 As shown in α), t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com