Wind energy recycling system for livestock and poultry house

A recovery system and technology for livestock and poultry houses, applied in the field of wind energy recovery systems for livestock and poultry houses, can solve problems such as insufficient wind energy recovery and utilization efficiency, insufficient installation and operation flexibility, and unsatisfactory wind effects, so as to promote industrial structure adjustment, The scale of the project is easy to adjust, and the effect of promoting the application of clean energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

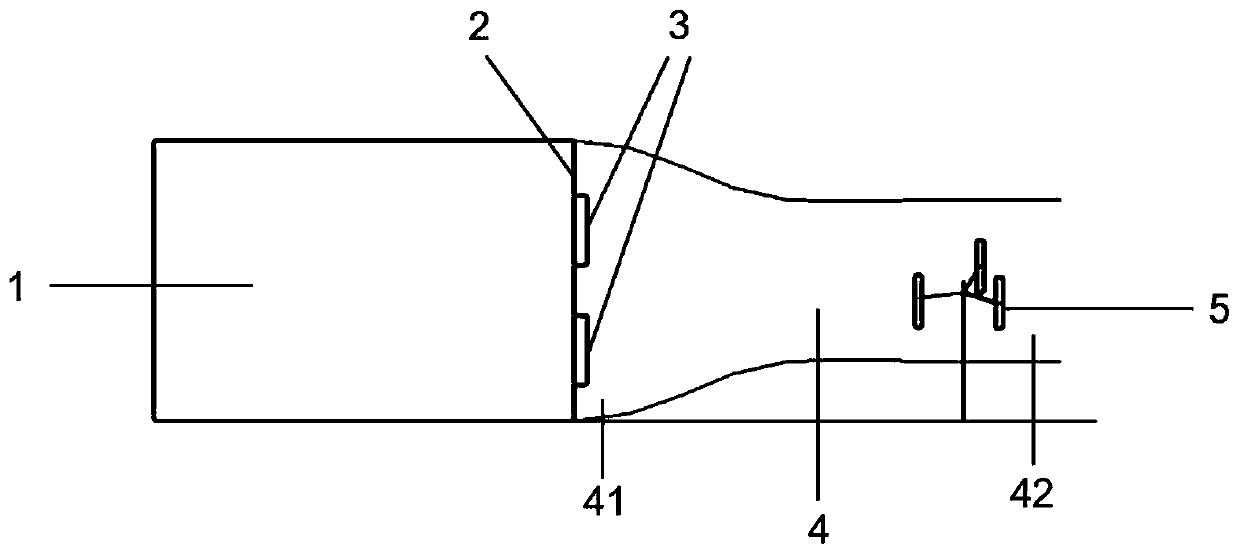

Embodiment 1

[0090] The number and distribution of the ventilating fans on the gable at the rear end of the poultry house and the initial exhaust wind speed of the ventilating fans are the same as in Comparative Example 1. The difference is that in Embodiment 1, the air flow guiding device of the present disclosure is added on the gable at the rear end of the poultry house. The device is surrounded by wall panels, and its large mouth end surrounds 10 ventilation fans on the gable at the rear end of the poultry house. The length of the longitudinal axis of the airflow guide device is 12 meters, and the ratio of the cross-sectional area of the large mouth end to the small mouth end is 1:0.5. After being guided by the airflow guide device, the airflow velocity at the small mouth end rises to about 10m / s. 5 vertical-axis wind-driven generators (the same model as in Comparative Example 1) are arranged side by side in the small mouth end of the airflow guiding device, about 10 meters away from ...

Embodiment 2

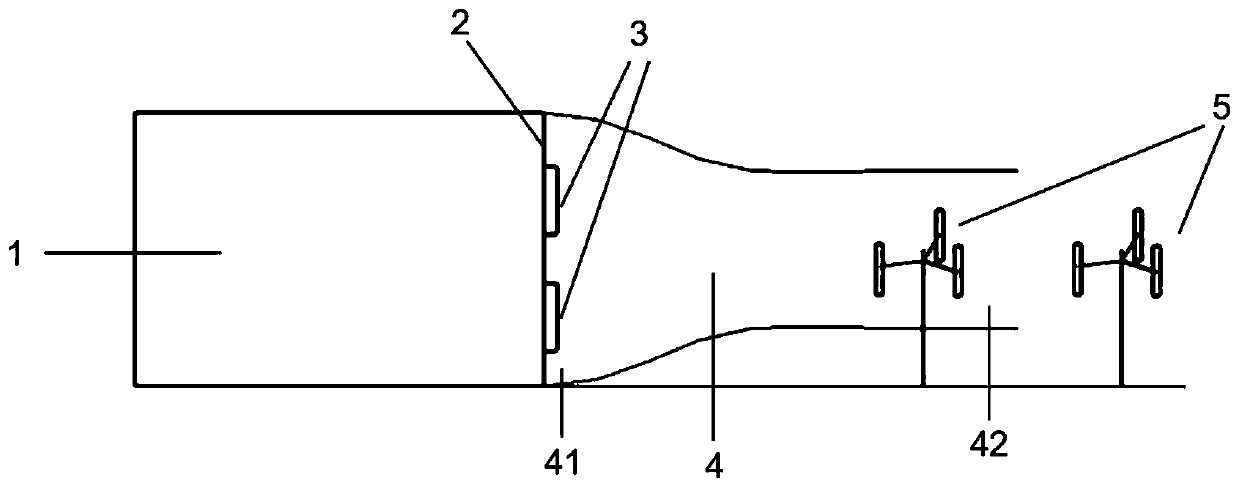

[0105] In a large-scale farm B, 10 ventilation fans are installed on the gable at the back end of the poultry house, and the average exhaust wind speed of each ventilation fan is about 5m / s. The airflow guiding device of the present disclosure is added on the gable at the rear end of the poultry house, and the large mouth end of the airflow guiding device surrounds 10 ventilation fans on the gable at the rear end of the poultry house. The length of the longitudinal axis of the airflow guiding device is 12 meters, and the ratio of the cross-sectional area of the large mouth end to the small mouth end is 1:0.5. After being guided by the airflow guiding device, the flow velocity of the airflow at the small mouth end increases to about 10m / s.

[0106] Set two vertical-axis wind turbines A at the small mouth end of the airflow guiding device 5 、A 6 (A 5 、A 6 The model of A in Comparative Example 2-1 0 same). A 5 、A 6 placed in parallel at the small port end of the air gui...

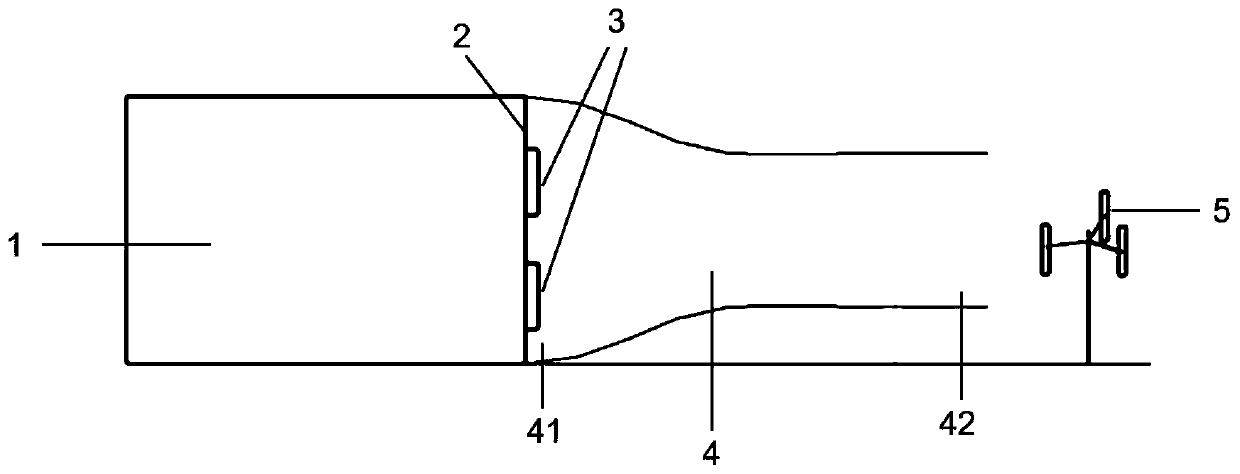

Embodiment 3

[0113] In Embodiment 3, the layout of the poultry house ventilation fan, the exhaust wind speed of the ventilation fan, and the parameters of the airflow guiding device are the same as in Embodiment 2, but three vertical axis wind-driven generators A are set in Embodiment 3 10 、A 11 、A 12 (Models are all the same as A in Comparative Example 2-1 0 same). Among them, A 10 、A 11 The arrangement is the same as that of A in Example 2 5 、A 6 the same, A 12 then in A 10 、A 11 The leeward position of A 12 in A 10 、A 11 on the perpendicular bisector of A 12 The wind wheel center and A 10 、A 11 The distance between the midpoints of the lines between the centers of the wind wheels is 3 meters.

[0114] After calculation, A 10 The power generation efficiency is about 25%, A 11 The power generation efficiency is about 25%, A 12 The power generation efficiency is about 20%. A 10 、A 11 、A 12 The total generating power of the composed wind power generating set is about 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Generating power | aaaaa | aaaaa |

| Generating power | aaaaa | aaaaa |

| Generating power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com