Cut tobacco support strength detection method and detector

A technology of support strength and detection method, which is applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, instruments, etc., can solve the problems of difficulty in measuring the softness of shredded tobacco, small amount of short removal, and large amount of short removal. To achieve the effect of improving the quality of cigarette products, the influence of human factors is small, and the measurement accuracy is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

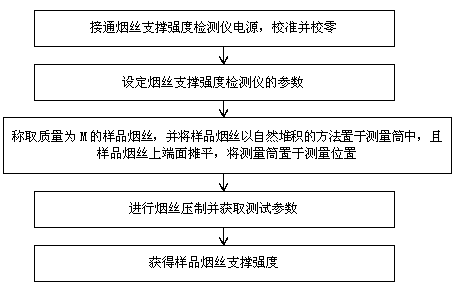

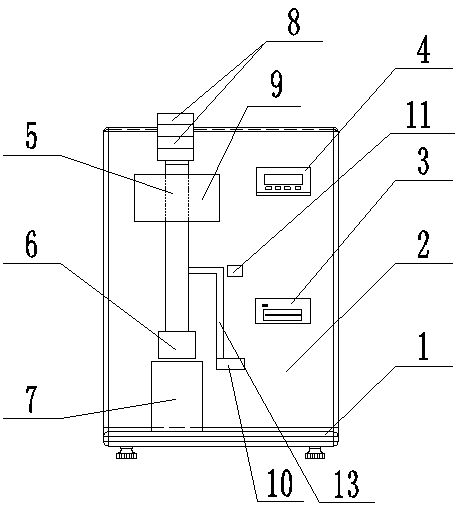

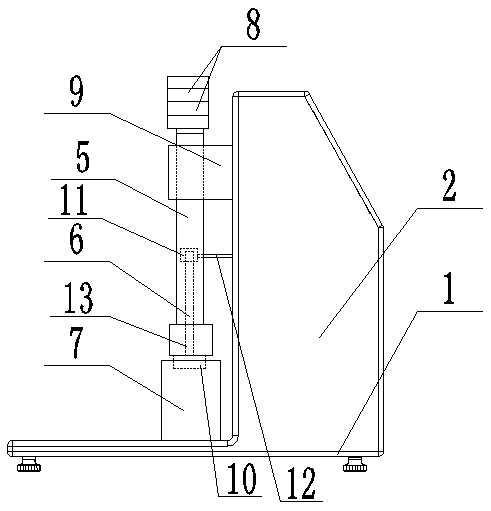

[0031] Such as figure 1 Shown: shredded tobacco supporting strength detection method of the present invention, comprises the following steps:

[0032] Step 1: Turn on the power of the shredded tobacco support strength detector, calibrate and zero;

[0033] Step 2: Set the parameters of the shredded tobacco support strength detector: set the flattening time of the shredded tobacco pressing mechanism as T 1 , the flattened pressure is F 1 , set the pressing time of the shredded tobacco pressing mechanism as T 2 , the applied pressure is F 2 ;

[0034] Step 3: Weigh the sample shredded tobacco with a mass of M, and place the sample shredded tobacco in the measuring cylinder 7 in a natural accumulation method, and flatten the upper end surface of the sample shredded tobacco, and place the measuring cylinder 7 at the measuring position;

[0035] Step 4: Carry out shredded tobacco pressing and obtain test parameters: the detector control system controls the shredded tobacco pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com