Chopping-threshing combined longitudinal axial flow threshing separating device

A technology of threshing separation and longitudinal axial flow, which is applied in the direction of threshing equipment, cutters, agricultural machinery and implements, etc., can solve the problems of insufficient grasping ability of longitudinal axial flow threshing separation device, and achieve reduction of entrainment loss rate, accelerated separation, The effect of reducing tangling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

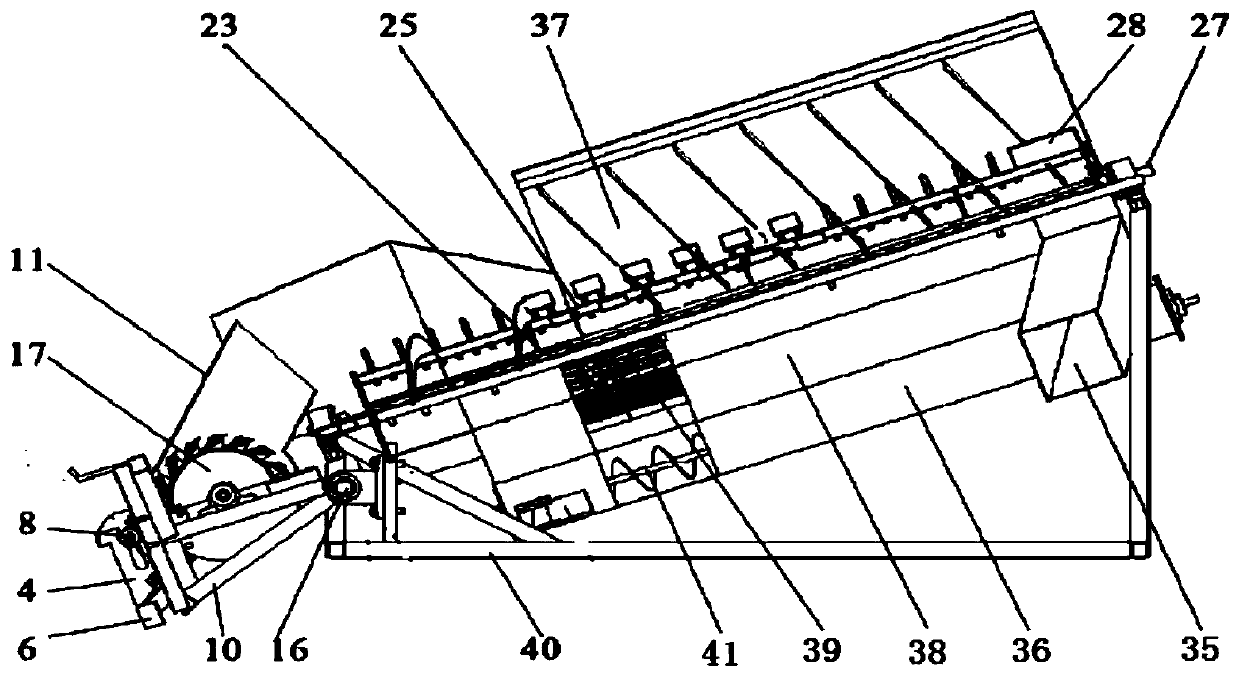

[0029] Such as figure 1 The cut-off combined longitudinal axial flow threshing and separating device includes a chopping device and a longitudinal axial flow threshing and separating device. The device is connected with the longitudinal axial flow threshing and separation device arranged obliquely vertically through the rotating shaft 16, and the chopping device can rotate around the rotating shaft 16 after being connected to the header.

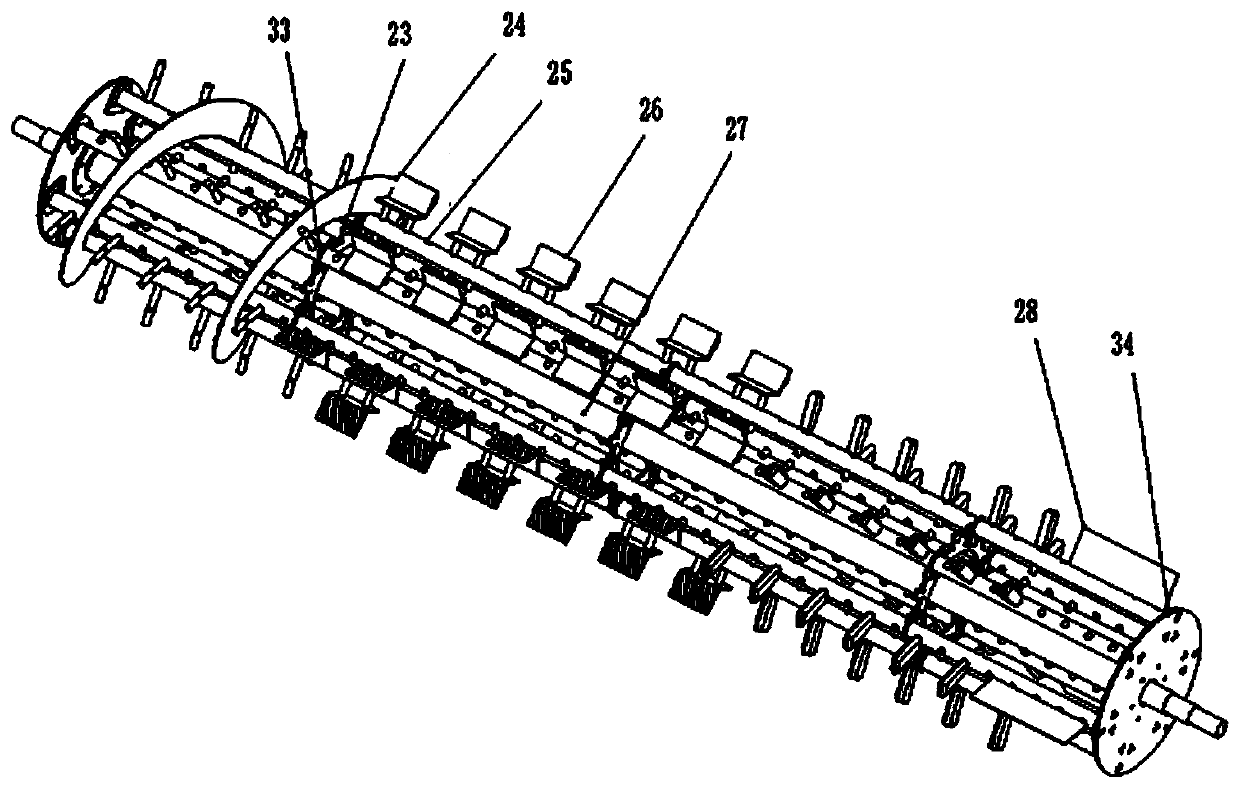

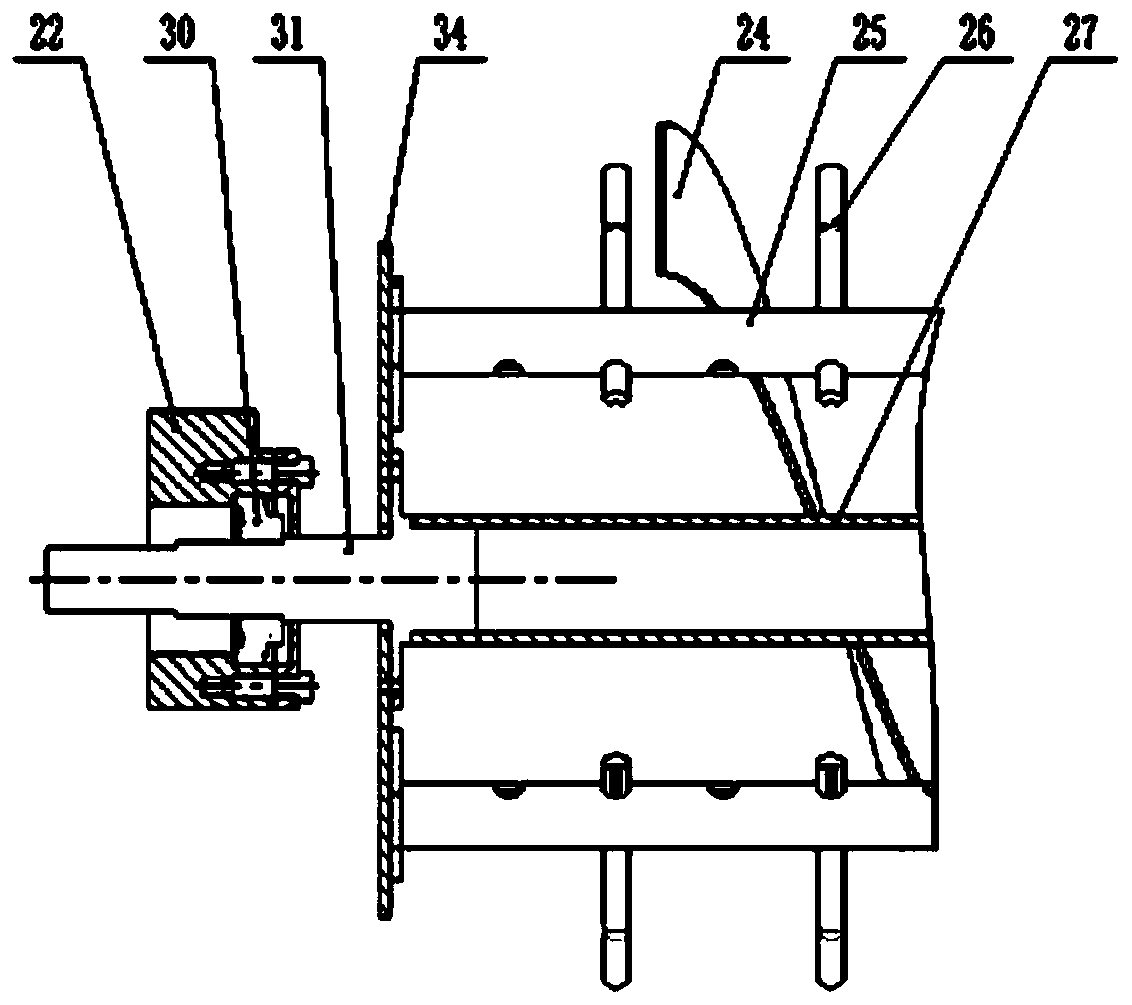

[0030] to combine figure 2 As shown, the longitudinal axial flow threshing separation device includes a threshing drum support 40, a threshing drum lower casing 38, a guide top cover 37, a longitudinal axial flow threshing drum with a drum shaft 27, and is installed on the longitudinal axial flow threshing drum in sequence along the axial direction. Concave plate screen cloth 39 below and deliver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com