Tubular heater as well as preparation method and application thereof

A tube heater and atomizer technology, which is applied in the field of electronic cigarettes, can solve the problems of inability to heat and volatilize smoke substances, poor electronic cigarette experience effect, poor heat storage effect of heating tubes, etc., and achieves good heat storage effect and heating effect. Even and ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

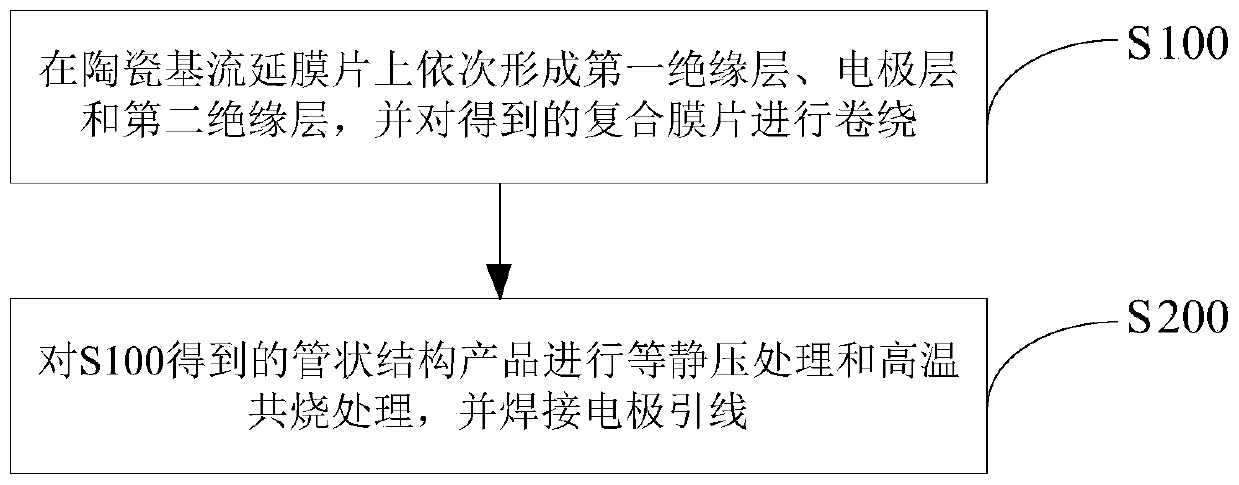

[0042] According to the first aspect of the present invention, the present invention provides a method for preparing a tubular heater. According to an embodiment of the present invention, refer to figure 1 , the method includes:

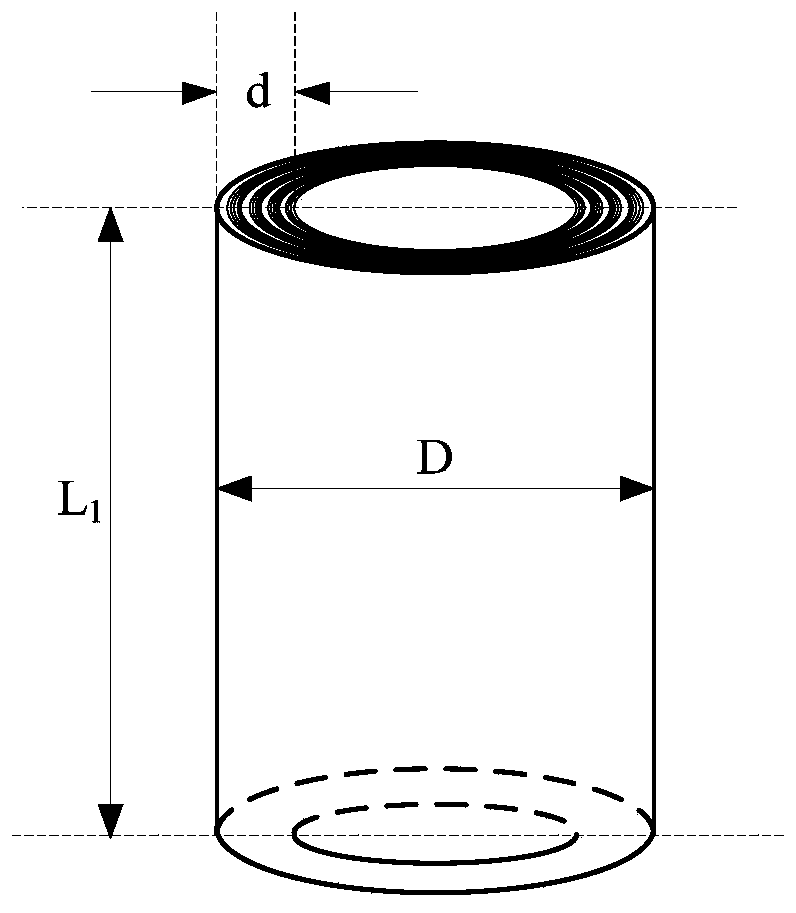

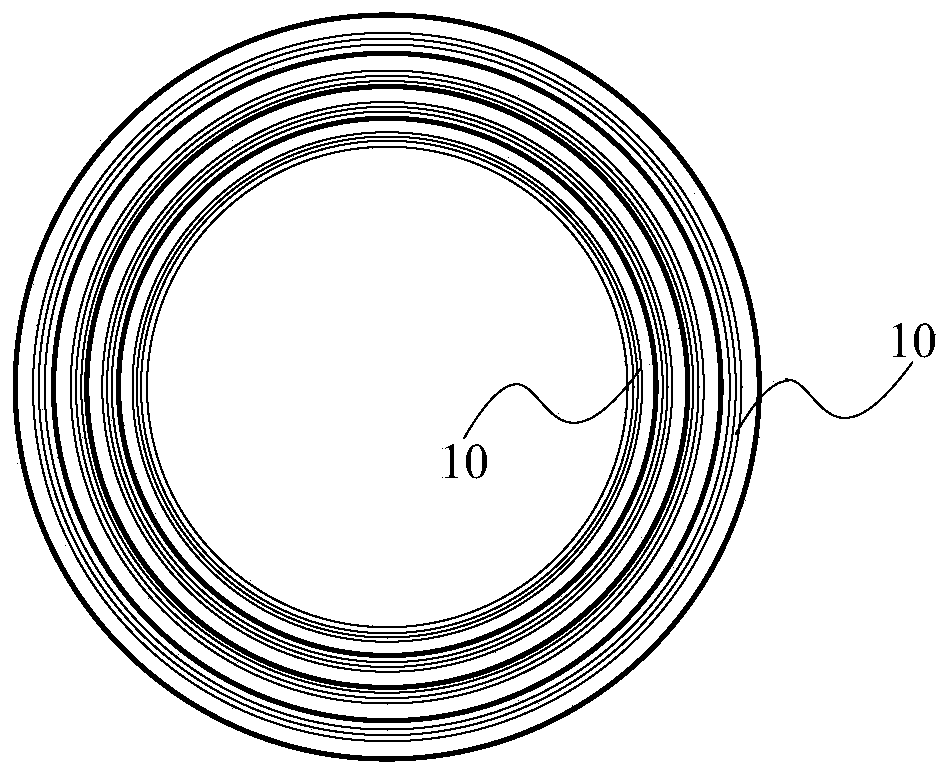

[0043] (1) providing a ceramic-based casting film; (2) forming a first insulating layer on at least a part of the surface of the casting film; (3) forming an electrode layer on at least a part of the surface of the first insulating layer; (4) Form a second insulating layer on at least a part of the surface of the electrode layer; (5) wind the composite diaphragm obtained in step (4) so as to form a tubular structure with a multilayer heater assembly, wherein the heater assembly is formed from From the outside to the inside, it includes a cast membrane support layer, a first insulating layer, an electrode layer and a second insulating layer; (6) performing isostatic pressing and high-temperature co-firing on the tubular structure product obtained i...

Embodiment 1

[0068] To prepare a tubular heater, the steps are as follows:

[0069](1) Select a cast film of 1.5YSZ (that is, zirconia with a yttrium oxide content of 1.5mol%) with a thickness of 0.03mm, and the cut size is: (L×W=61×13mm); (2) pass through a silk screen The way of printing is to print the aluminum oxide with a purity of 55wt% to the designated position of the casting film, the printing thickness is 5um, and it is dried at 75°C for 10min to form the first insulating layer; (3) on the first insulating layer Print Pt high-temperature resistance wire on the top, and the Pt heating wire is completely printed on the first insulating layer of alumina layer, with a printing thickness of 5um; dry at 75°C for 10 minutes to form an electrode layer; (4) The printing purity on the electrode layer is 55wt% Aluminum oxide, printed with a thickness of 5um, dried at 75°C for 10 minutes to form a second insulating layer, the second insulating layer overlaps with the first insulating layer, ...

Embodiment 2

[0072] To prepare a tubular heater, the steps are as follows:

[0073] (1) Select a cast film of 2YSZ (that is, zirconia with a yttrium oxide content of 2mol%) with a thickness of 0.05mm, and the cut size is: (L×W=91×38mm); (2) through screen printing method, the aluminum oxide with a purity of 75wt% is para-printed to the designated position of the cast film, the printing thickness is 10um, and it is dried at 75°C for 10min to form the first insulating layer; (3) Printing on the first insulating layer Pt high temperature resistance wire, Pt heating wire is completely printed on the alumina layer of the first insulating layer, the printing thickness is 7.5um, and it is dried at 75°C for 10min to form an electrode layer; (4) the electrode layer is printed with a purity of 75wt%. Alumina, the printing thickness is 10um, and it is dried at 75°C for 10 minutes to form a second insulating layer, the second insulating layer overlaps with the first insulating layer, and the first ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com