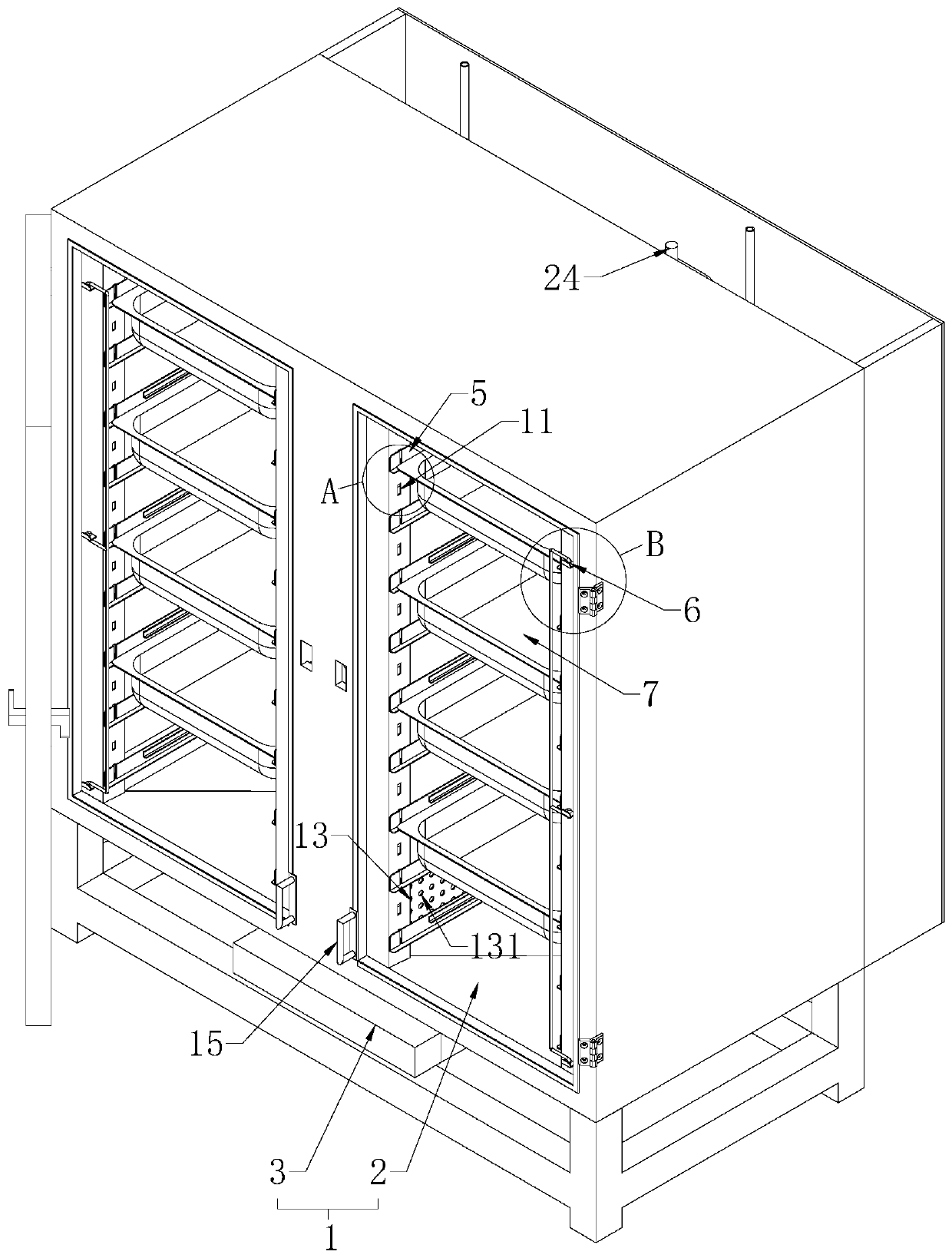

Parallel type steaming box

A technology of parallel connection and steam box, applied in the field of steam box, which can solve the problems of high equipment cost and achieve the effects of improving safety, saving heat energy, good practicability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

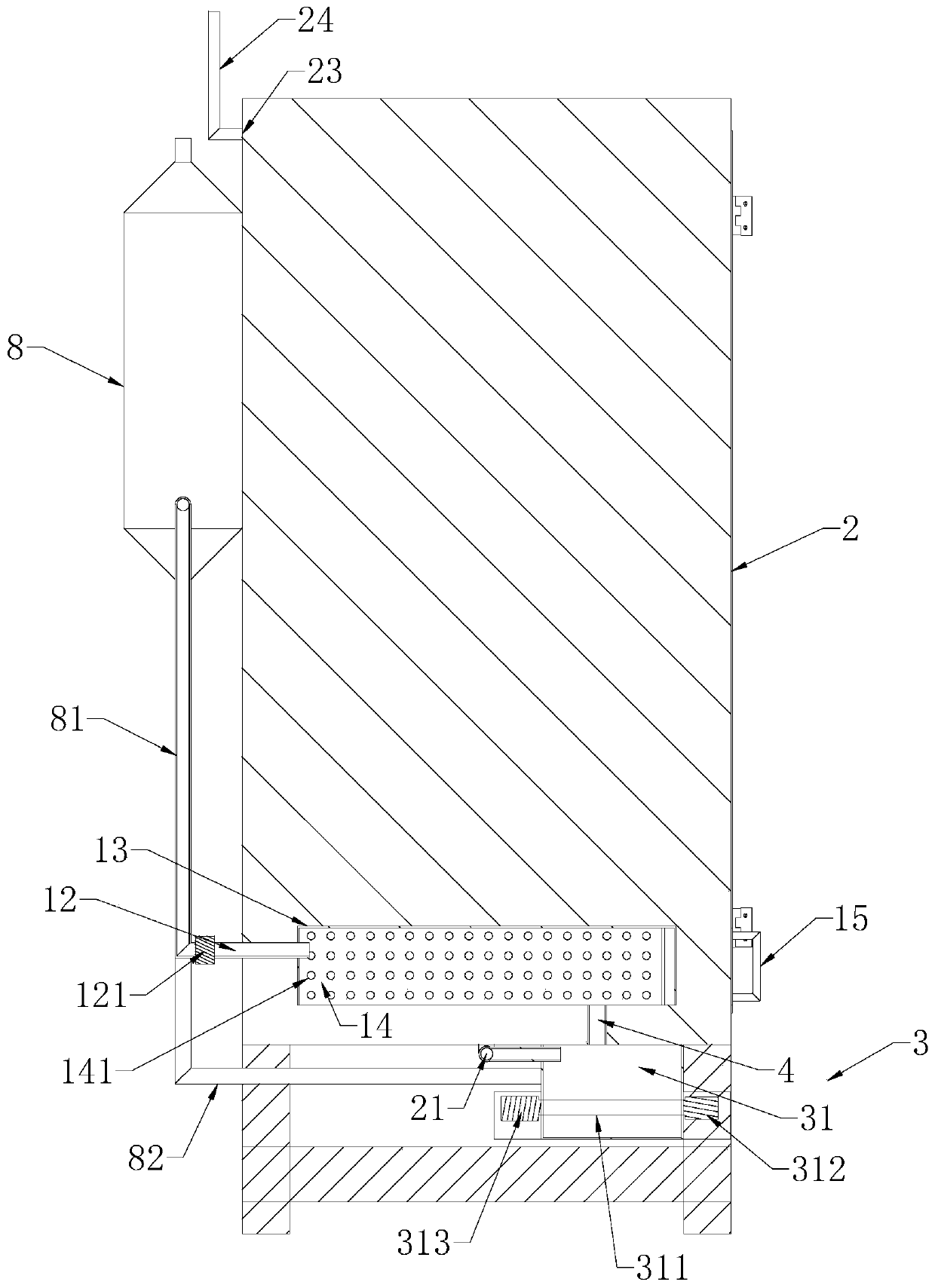

Method used

Image

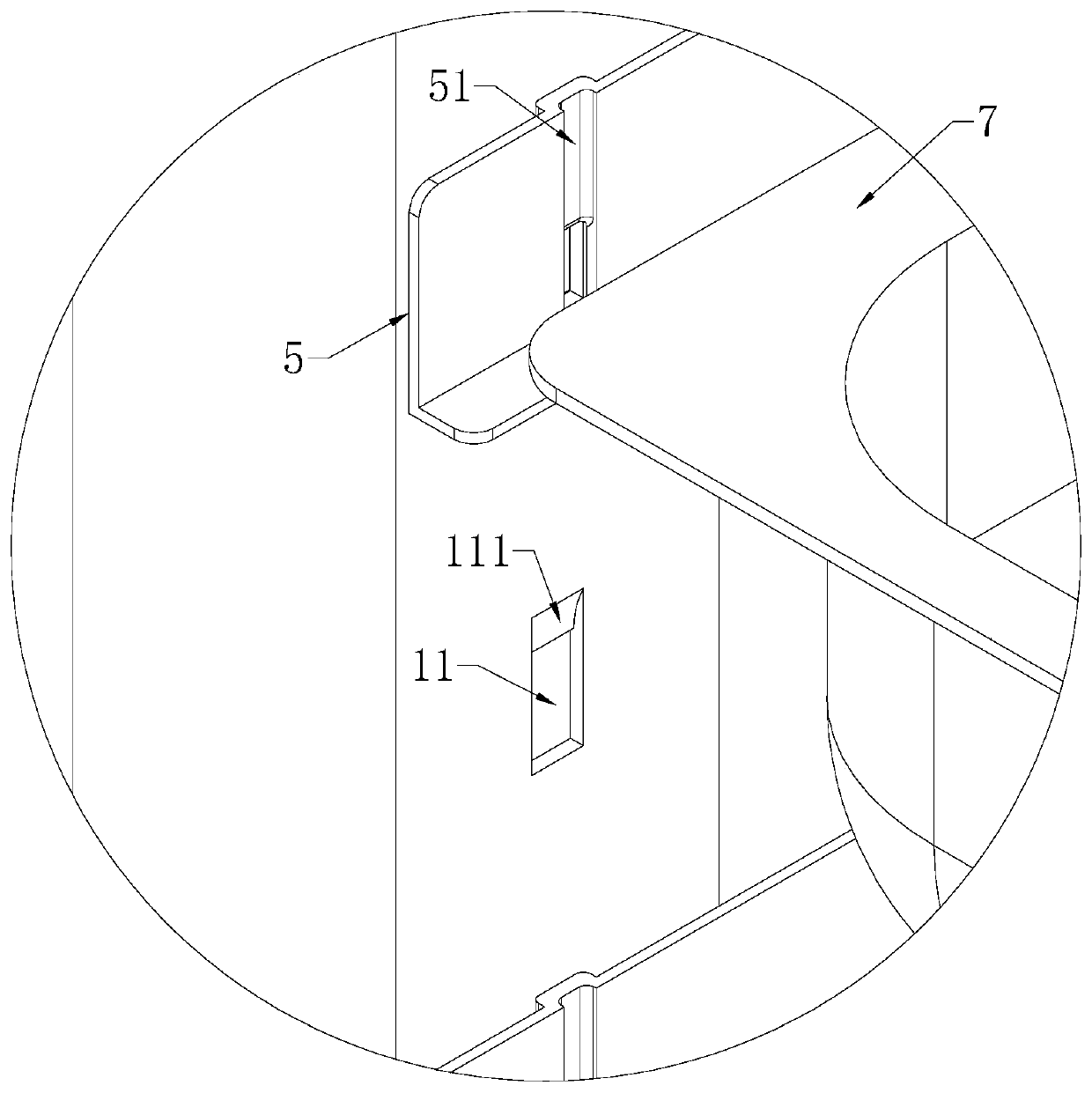

Examples

Embodiment 2

[0061] Such as Figure 9 As shown, a parallel steam box differs from Embodiment 1 in that the connection position of the air inlet of the pressure relief pipe 12 is different. In this embodiment, the air inlet of the pressure relief pipe 12 is connected to the side wall of the water tank 31 of the steam generating chamber 3, then when the pressure in the food steaming chamber 2 increases, the steam pressure in the water tank 31 will When the critical value is reached, the pressure value detector in the water tank 31 triggers the valve 121 to open, and the hot steam in the water tank 31 can enter into the cooling tower 8 through the pressure relief pipe 12 and condense into cooling water, which solves the problems of the water tank 31 and the steam pipeline. 4 and the fairing 13, the problem that the hot steam cannot be discharged smoothly due to the excessive internal pressure of the food steaming chamber 2, and at the same time solve the problem that the internal pressure of ...

Embodiment 3

[0065] to combine Figure 10 and Figure 11 As shown, a parallel steam box differs from Embodiment 1 in that the direction of movement of the sealing plate 14 is different. In this embodiment, the sealing plate 14 is vertically slidably disposed in the fairing 13 , and the sealing plate 14 is connected with a driving member 9 for driving its vertical movement; in this embodiment, the driving member 9 is configured as an air cylinder. When the driving member 9 vertically drives the sealing plate 14 and rises to the limit position, the air vent 141 of the fairing 13 is closed; open.

[0066] Below in conjunction with specific action this embodiment is further elaborated:

[0067] According to the actual needs, the user can choose the single-side supply mode or the two-way supply mode, that is, the sealing plate 14 is automatically driven to perform vertical lifting movement through the driving member 9. Adopting this kind of lifting movement mode is conducive to improving the...

Embodiment 4

[0069] to combine Figure 11 and Figure 12 As shown, a parallel steam box differs from the third embodiment in that the vertical sliding movement distance of the sealing plate 14 is different. In this embodiment, the air vent 141 is also opened on the sealing plate 14, then when the driving member 9 drives the sealing plate 14 to move vertically, and the air vent 141 of the sealing plate 14 is aligned with the air outlet 131 of the fairing 13. , hot steam can enter the food steaming chamber 2 through the fairing 13; and when the driving member 9 reversely drives the sealing plate 14 to move vertically, and the air holes 141 of the sealing plate 14 and the air outlet holes 131 of the fairing 13 are closed alternately At this time, the hot steam cannot enter the food steaming chamber 2, so as to realize the purpose of selecting the one-side supply mode or the two-way supply mode.

[0070] Below in conjunction with specific action this embodiment is further elaborated:

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com