Side Spray Cooling Mechanism and Cooling Method of Hot Forging Die Frame

A cooling mechanism and hot forging die technology, applied in heating/cooling equipment, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problems of workshop working environment pollution, untimely cooling, surge, etc., and achieve optimized cooling effect , The cooling process is stable, and the effect of simplifying the cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

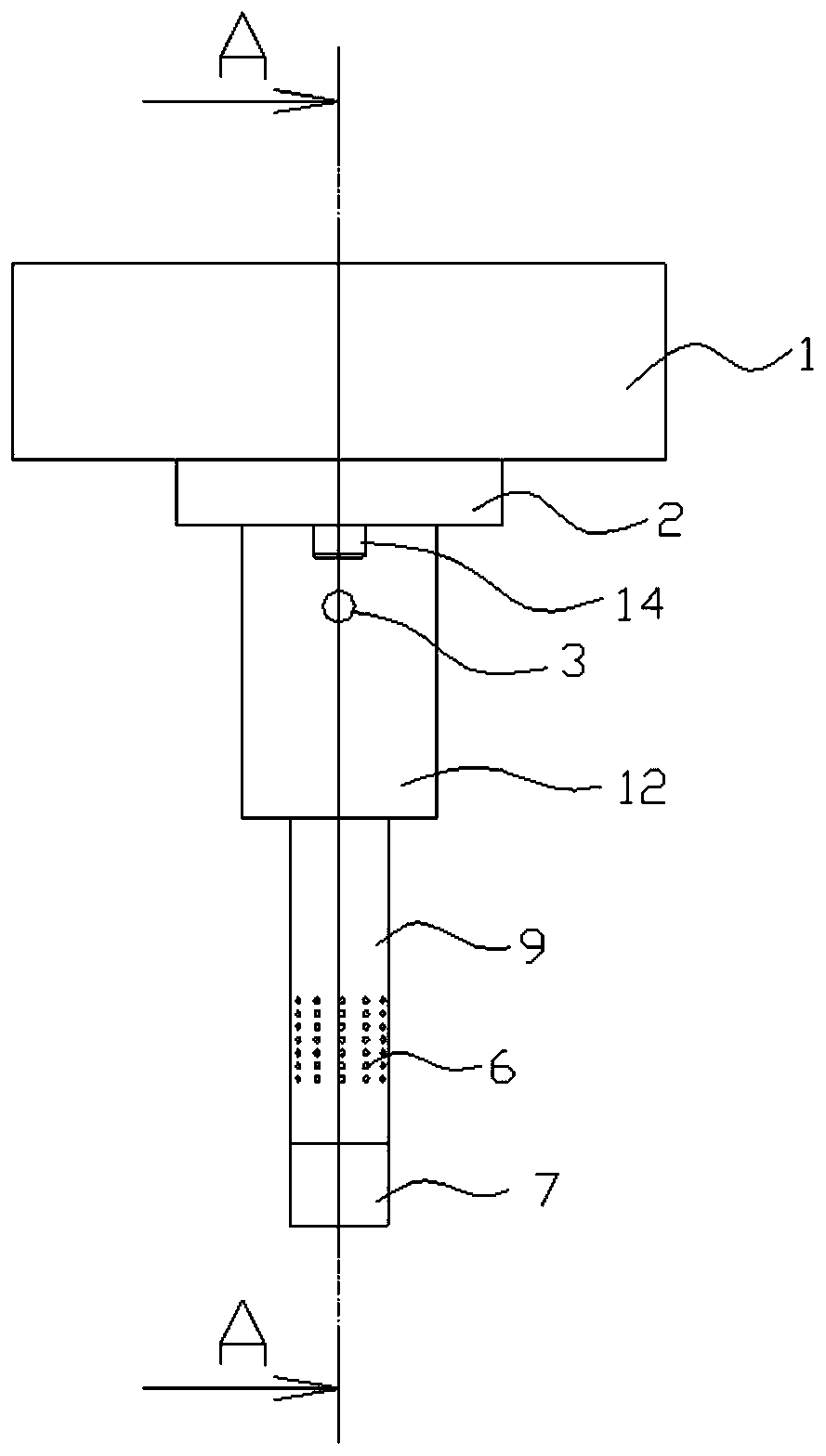

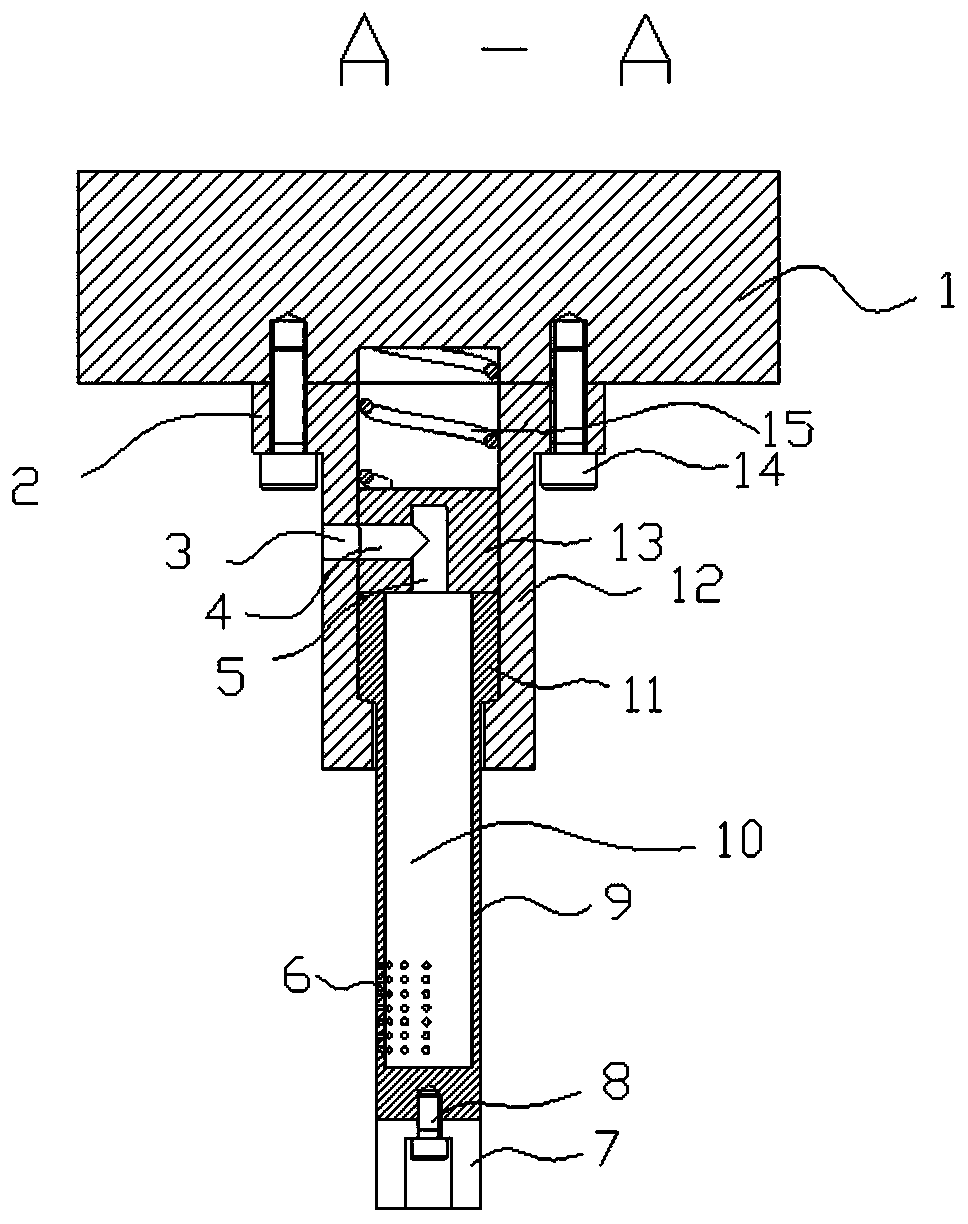

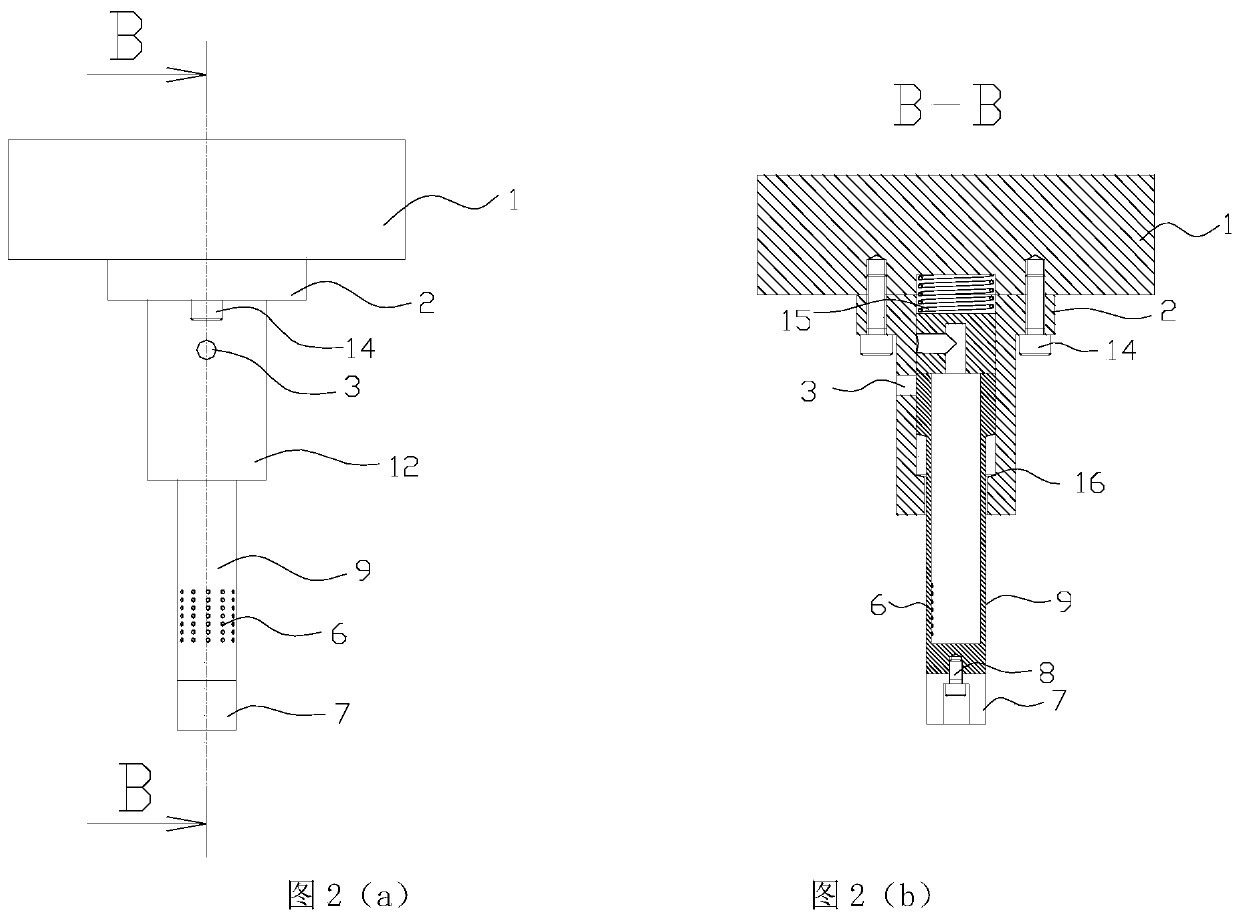

[0034] This hot forging die frame uses a side spray cooling mechanism, including a fixed sleeve 12 and a nozzle module 9, the fixed sleeve 12 is axially penetrated through the hollow, the side wall of the fixed sleeve 12 is provided with a diversion port 3, and the upper part of the nozzle module 9 is the same as The shaft sleeve is set in the fixed sleeve 12, the lower part of the nozzle module 9 extends outside the fixed sleeve 12, the upper edge of the fixed sleeve 12 is provided with a flange 2, and the flange 2 is provided with several through holes through which the screws 14 pass Through holes, and screwed into the upper mold template 1, the fixing sleeve 12 is fixed below the upper mold template 1.

[0035] The axial center of the spray head module 9 is provided with a spray chamber 10, the upper end of the spray chamber 10 is an open end, and the lower end is a blind end, and the side wall of the spray head module 9 near the bottom is provided with several nozzles 6. ...

Embodiment 2

[0042] In order to protect the bottom of the nozzle module 9 and prevent hard impact during use, a protective cover 7 is provided under the nozzle module 9, and the protective cover 7 can be made of a material with certain elasticity to play a buffering effect. The protective cover 7 is in the shape of a cylinder, and the axial center of the protective cover 7 is provided with a screw plug hole, and the bolt 8 passes through the screw plug hole and is tightened on the lower end of the nozzle module 9 to fix the protective cover 7 .

Embodiment 3

[0044] In order to be able to install a spring 15 of sufficient length, a groove is provided in the place where the upper die template 1 contacts the spring 15, and the top of the spring 15 is located in the groove. The aperture of the groove is consistent with the aperture of the fixed sleeve 12 .

[0045] Attached Figure 1(a), Figure 1(b) and Attached figure 2 The two states of the present invention are given, and the application scenarios of the present invention are further described below in combination with methods.

[0046] A side spray cooling method for a hot forging die frame, comprising the following steps:

[0047] Step 1: Install the side spray cooling mechanism: Install the above-mentioned side spray cooling mechanism under the upper mold template 1 of the hot forging die frame, and let the nozzle 6 face the punch, and the distance between the punch and the nozzle 6 is smaller than the nozzle 6. The stroke of the coolant to ensure that the coolant can be sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com