Roller deflected liner device for pipe welding

A liner and roller technology, which is applied in the field of roller deflection liner devices, can solve the problems of narrow radial space, low load-bearing strength of welding seams, block liners cannot have shallow arc grooves, etc., and achieve convenient operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

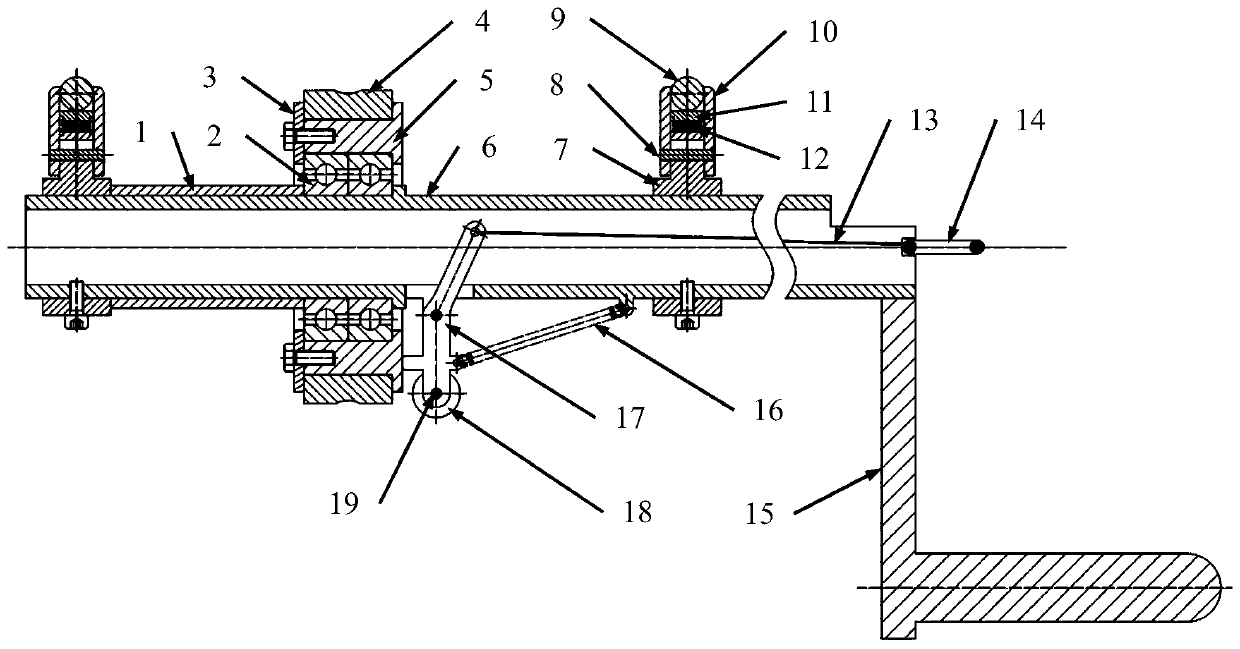

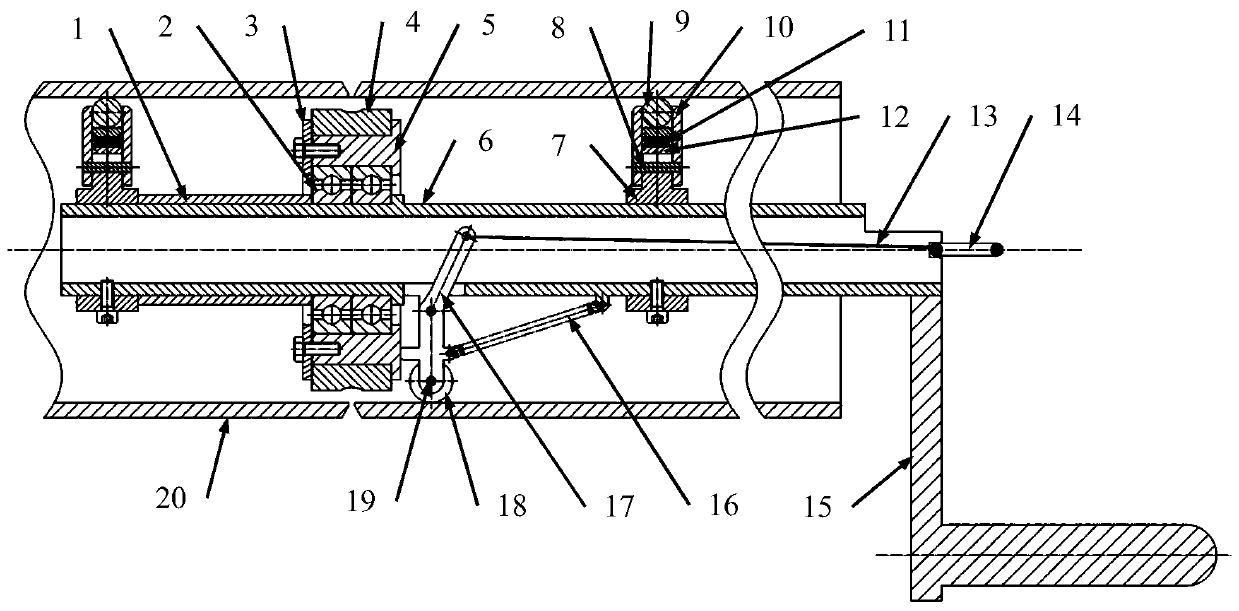

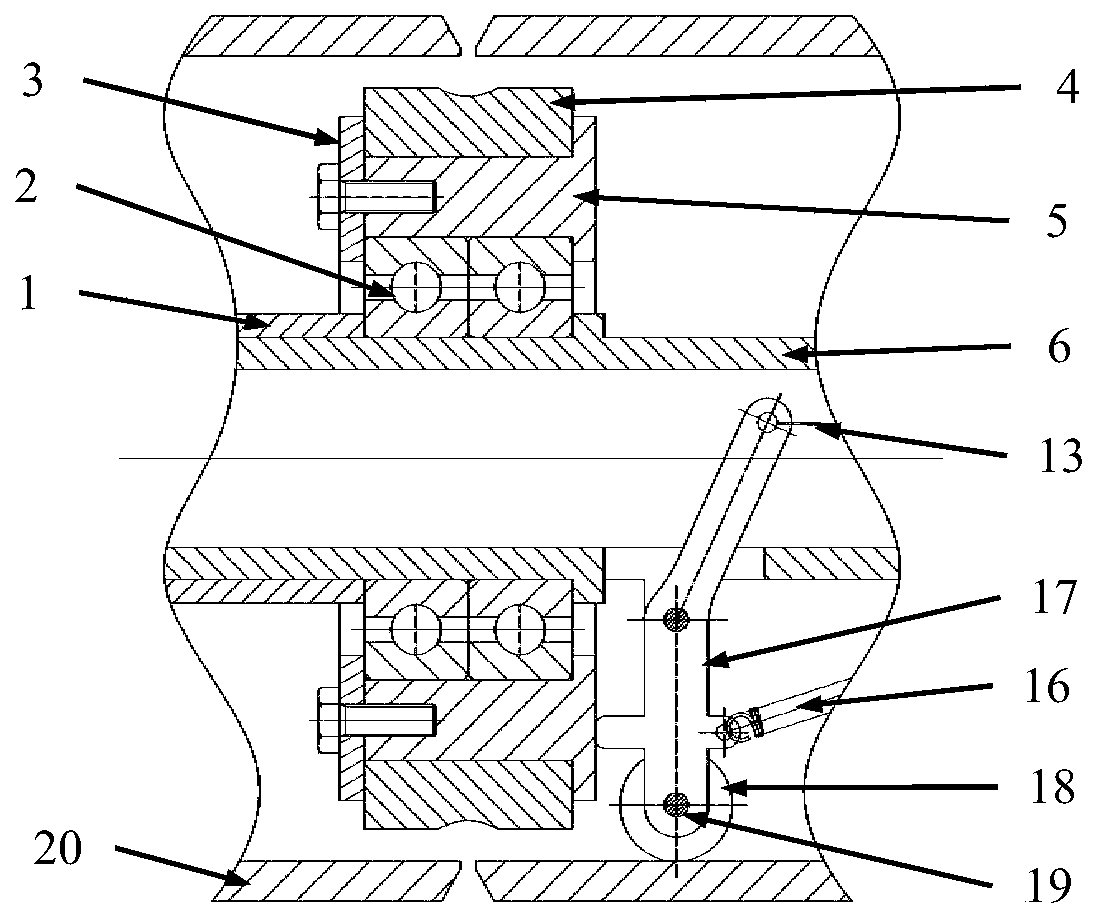

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] The technical solution adopted by the present invention to solve the technical problem is: the device consists of four parts: a pad roller part, a supporting partial top part, a long tube rotating part, and a retractable and separated part.

[0034] The liner roller part includes: an annular liner, a liner holder, a bearing, and a retaining ring, which are used to make the liner close to the inner wall of the steel pipe to seal off the welding groove.

[0035] The material of the annular liner is ceramic or copper alloy material, the shape of the liner is circular, the outer diameter is slightly smaller than the inner diameter of the steel pipe to be welded, and there is an arc-shaped shallow groove in the middle of the outer wall of the liner, which is used to form micro-protrusions The shape of the weld seam; the annular gasket is installed on the gasket cylinder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com