Screw screwing machine

A screw machine and screw driver technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, complex procedures, and complex structures, so as to control costs, improve synchronization rate and efficiency, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

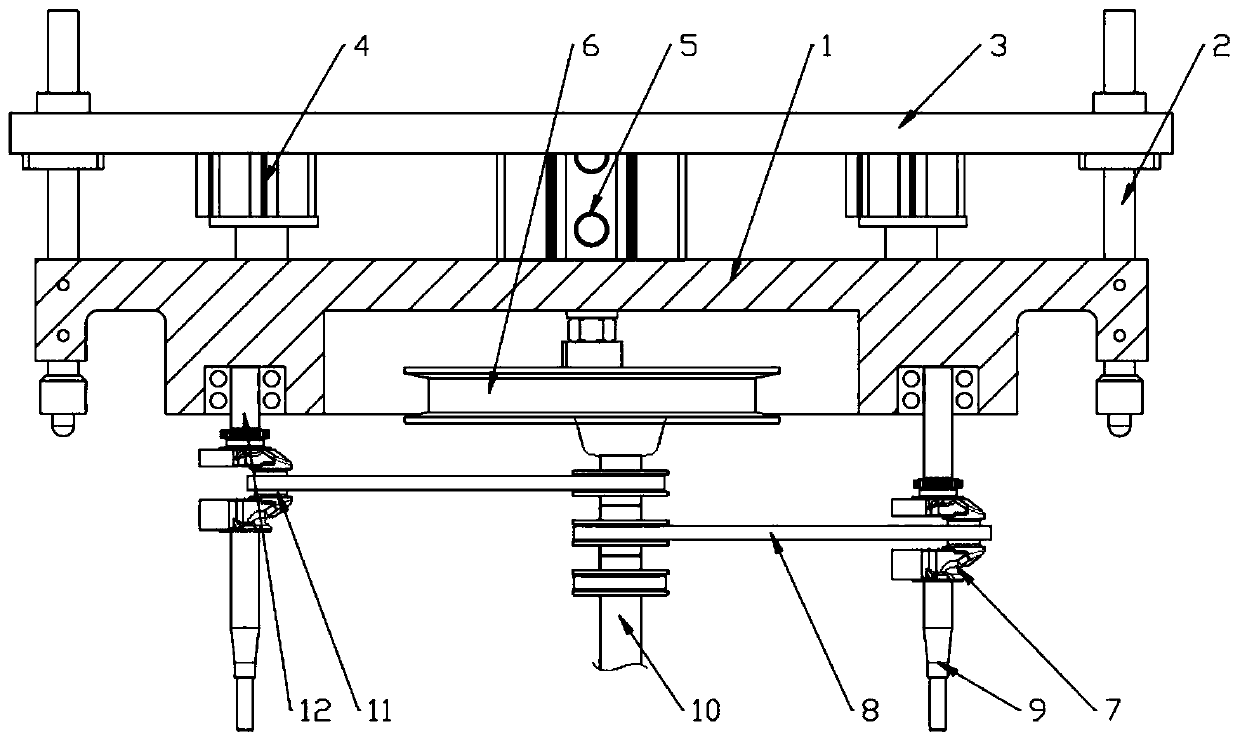

Embodiment 1

[0040] Use the electromagnet 4b and the metal block 4c as the clutch assembly to perform the screwing operation, and the operation steps are as follows:

[0041] Step 1. The workpiece is moved to the bottom of the substrate 1;

[0042] Step 2. Disconnect the power supply of electromagnet 4b;

[0043] Step 3. The metal block 4c loses its magnetic adsorption;

[0044] Step 4. Substrate 1 falls;

[0045] Step 5. The functional block 9 falls synchronously, and its cutter head is located at the screw;

[0046] Step 6. Start the motor 5, and the motor 5 drives the driving wheel 6 to rotate;

[0047] Step 7. The guide post 10 revolves around the center of the drive wheel;

[0048] Step 8. The connecting rod 8 rotates synchronously;

[0049] Step 9. The connecting rod 8 drives the driven wheel 7 and the connecting ring 12 to rotate synchronously through the pivot pin 11;

[0050] Step 10. The driven wheel 7 drives the screwdriver 9 to rotate;

[0051] Step 11. When the head of ...

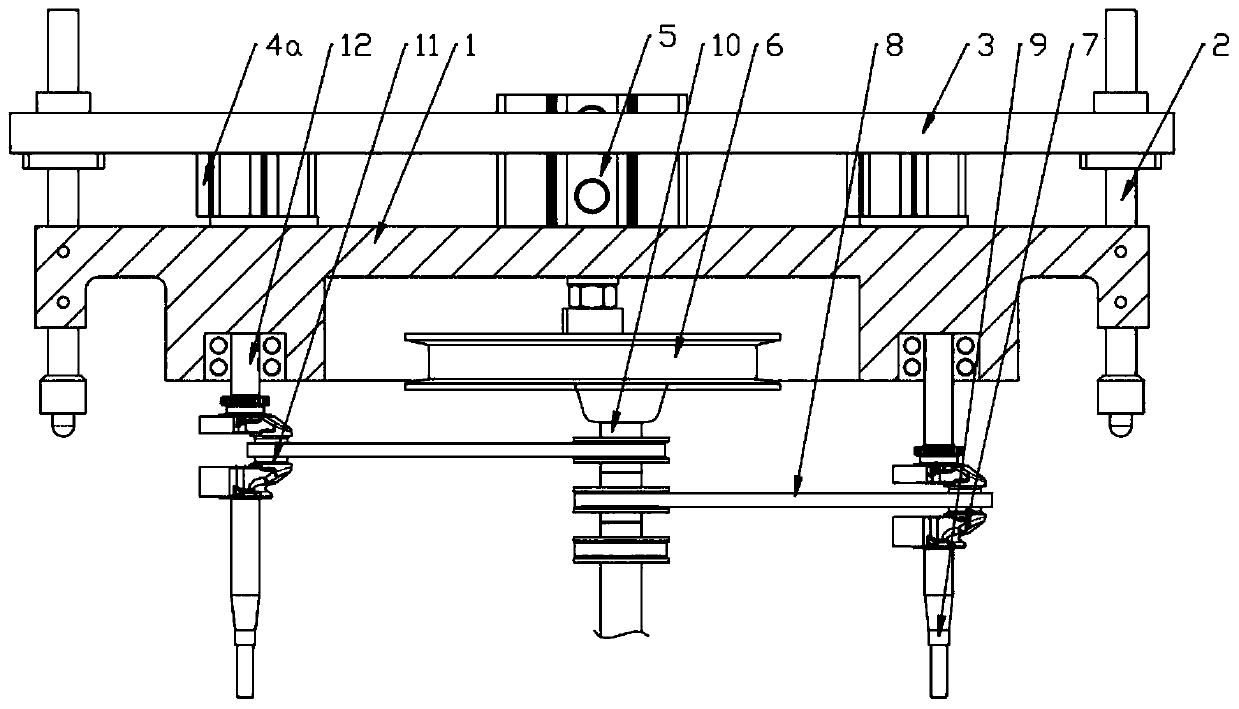

Embodiment 2

[0059] Use the cylinder as the clutch assembly to carry out the screwing operation, and the operation steps are as follows:

[0060] Step 1. The workpiece is moved to the bottom of the substrate 1;

[0061] Step 2. Start cylinder 4a;

[0062] Step 3. The cylinder shaft of cylinder 4a moves downward;

[0063] Step 4. Substrate 1 falls;

[0064] Step 5. The functional block 9 falls synchronously, and its cutter head is located at the screw;

[0065] Step 6. Start the motor 5, and the motor 5 drives the driving wheel 6 to rotate;

[0066] Step 7. The guide post 10 revolves around the center of the drive wheel;

[0067] Step 8. The connecting rod 8 rotates synchronously;

[0068] Step 9. The connecting rod 8 drives the driven wheel 7 and the connecting ring 12 to rotate synchronously through the pivot pin 11;

[0069] Step 10. The driven wheel 7 drives the screwdriver 9 to rotate;

[0070] Step 11. When the head of the screwdriver 9 rotates synchronously, it fits with the s...

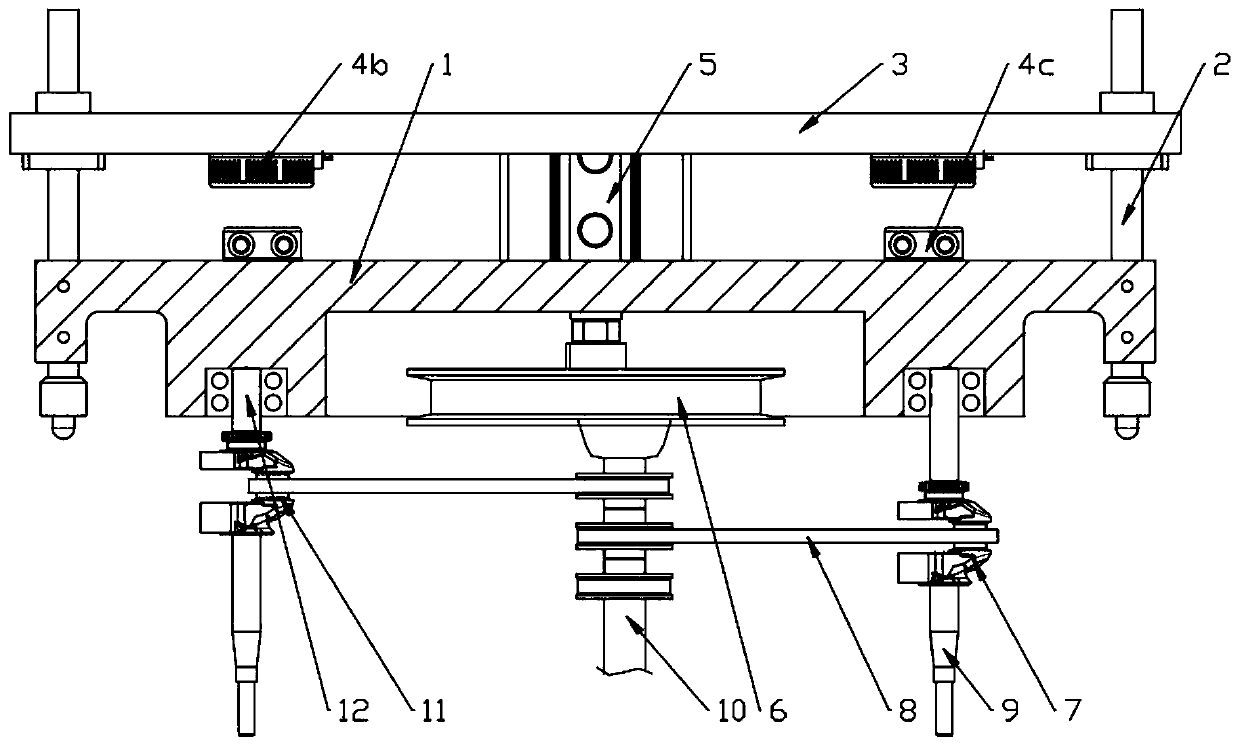

Embodiment 3

[0078] Installation of screwdriver 9:

[0079] Step 1. According to the workpiece, select a screw brush 9 with a suitable length and suitable for the cutter head;

[0080] Step 2. Insert the screwdriver 9 into the driven wheel 7 from bottom to top;

[0081] Step 3. Connect the through hole between the upper part of the screwdriver 9 and the side end of the driven wheel 7;

[0082] Step 4. Screw in the screw pin 13;

[0083] Step 5. Put the gasket 15 on the two ends of the screw pin 13;

[0084] Step 6. Screw the nuts 14 on both ends of the screw pin 13 and tighten them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com