A kind of preparation method of high softening point hydrogenated petroleum resin

A technology of hydrogenated petroleum resin and high softening point, which is applied in the field of petroleum resin and can solve the problems of limited use and poor compatibility of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The composition of C5 thermal dimerization ingredients is: 10.0wt% of cyclopentadiene, 7.0wt% of cyclopentene, 3.0wt% of n-pentene, 1.5wt% of 2-pentene, and the rest is diluting solvent methylcyclohexane.

[0032] C5 thermal dimerization ingredients were reacted in a stirred high-pressure polymerization kettle at a temperature of 250°C for 10 hours, and the obtained polymerization liquid was flashed at a vacuum degree of -0.090MPa and a temperature of 95°C to obtain light components C5 and heavy components C 10 Mixed ingredients. replace the above C 10 The mixed material was reacted at a temperature of 125°C for 36 hours under the action of anhydrous aluminum trichloride catalyst to obtain a polymerization reaction liquid; after that, the catalyst was removed by washing with 15% alkali solution, and washed repeatedly until it was neutral, then entered the rectification tower, and then Vacuum degree -0.085MPa, temperature 240 ℃ for rectification, the solvent can be reco...

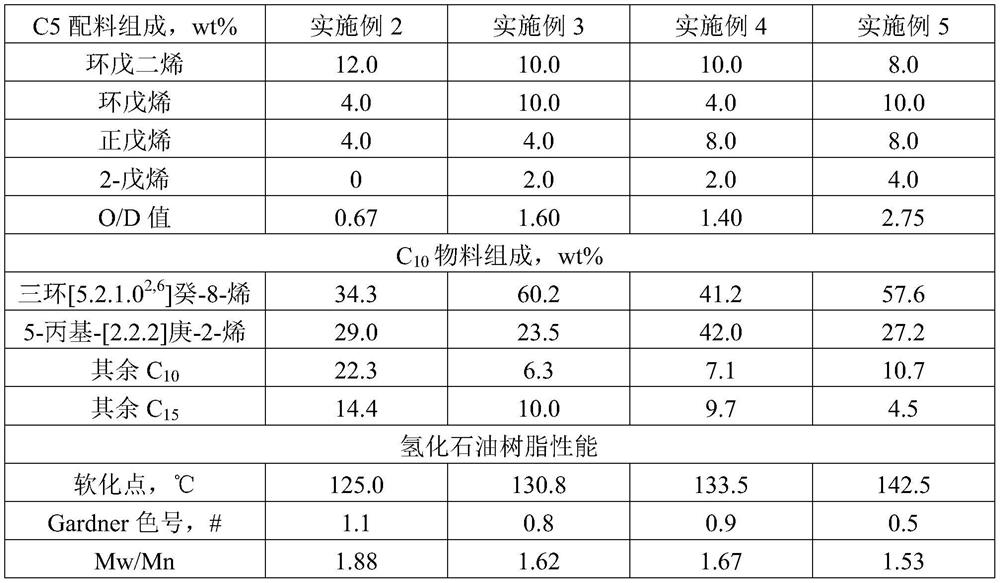

Embodiment 2~5

[0034] Using different C5 ingredients, under the same thermal dimerization reaction conditions and resin hydrogenation process, the obtained C 10 The composition and properties of hydrogenated petroleum resin are as follows:

[0035]

[0036] C5 thermal dimerization to C 10 The reaction conditions are: temperature 245°C, reaction time 10h; flash vacuum degree -0.085MPa, temperature 110°C;

[0037]The hydrogenation process conditions are: hydrogenation temperature 275°C, pressure 15MPa, LSHV 0.5h -1 .

[0038] It can be seen from the above table that when the ratio of monoolefin / diolefin (O / D value) in the ingredients is larger, the probability of side reactions is lower, and the C in the product 10 The higher the ratio, the C 15 The lower the ratio. The ratio of CPD to cyclopentene, n-pentene, etc. in the proportion will directly affect the softening point and molecular weight distribution (Mw / Mn) of hydrogenated petroleum resin.

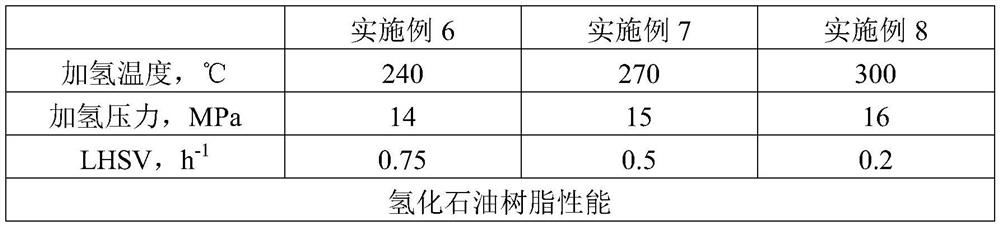

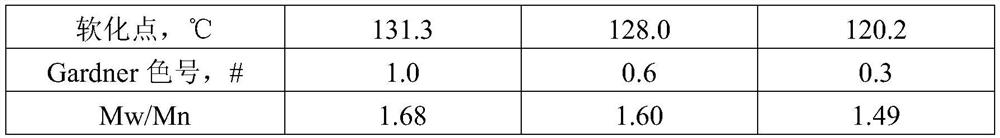

Embodiment 6~8

[0040] Using the same dark petroleum resin liquid to be hydrogenated, mixed with refined mineral oil with a distillation range of 280-350°C and a dynamic viscosity of 6.6cP at a mass ratio of 1:5.5 to obtain hydrogenation raw materials, and investigated the effects of different hydrogenation processes on hydrogenated petroleum resin The performance impact is as follows:

[0041]

[0042]

[0043] It can be seen from the above table that the hydrogenation temperature has the greatest influence on the hydrogenation decomposition rate of the resin, that is, the final softening point, which is the biggest influencing factor for the breaking of the molecular bonds of the resin, followed by the liquid hourly space velocity, and the reaction pressure has little influence on it. Liquid hourly space velocity (LHSV) is the biggest factor affecting the depth of hydrogenation reaction, and the color number is the lightest; the second is hydrogenation temperature and hydrogenation pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com