Skin-friendly extremely-thin high-permeability zero-leakage bottom film

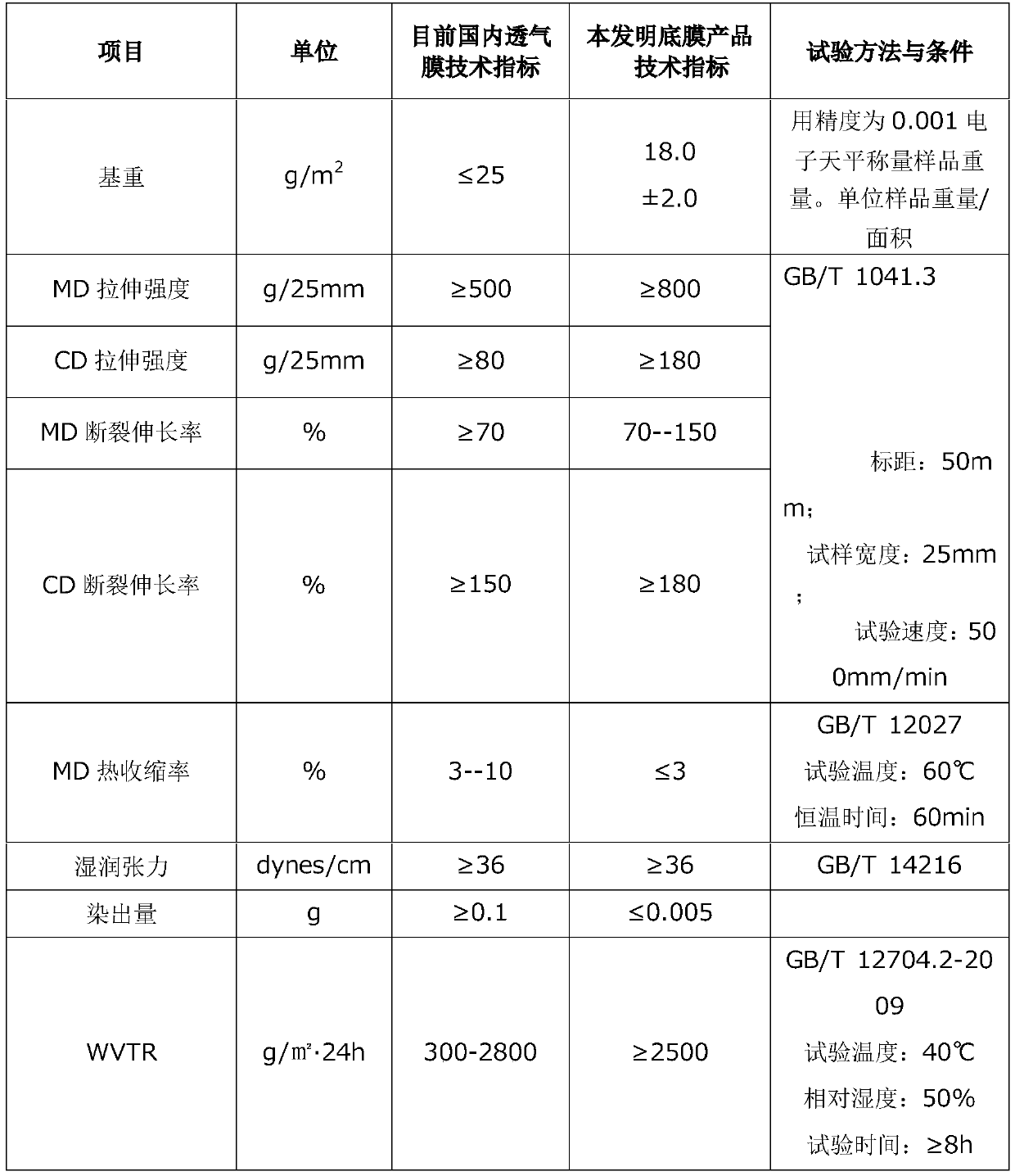

A highly breathable and extremely thin technology, applied in the field of film, can solve the problems of large leakage, low air flow, and difficulty in achieving high breathability and zero leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A skin-friendly, extremely thin, highly breathable and zero-leakage bottom film, which is composed of the following raw materials in weight percentages:

[0025] Nanoscale heavy CaCO 3 40%, metallocene polyolefin mLLDPE 12%, and the rest is low density polyethylene.

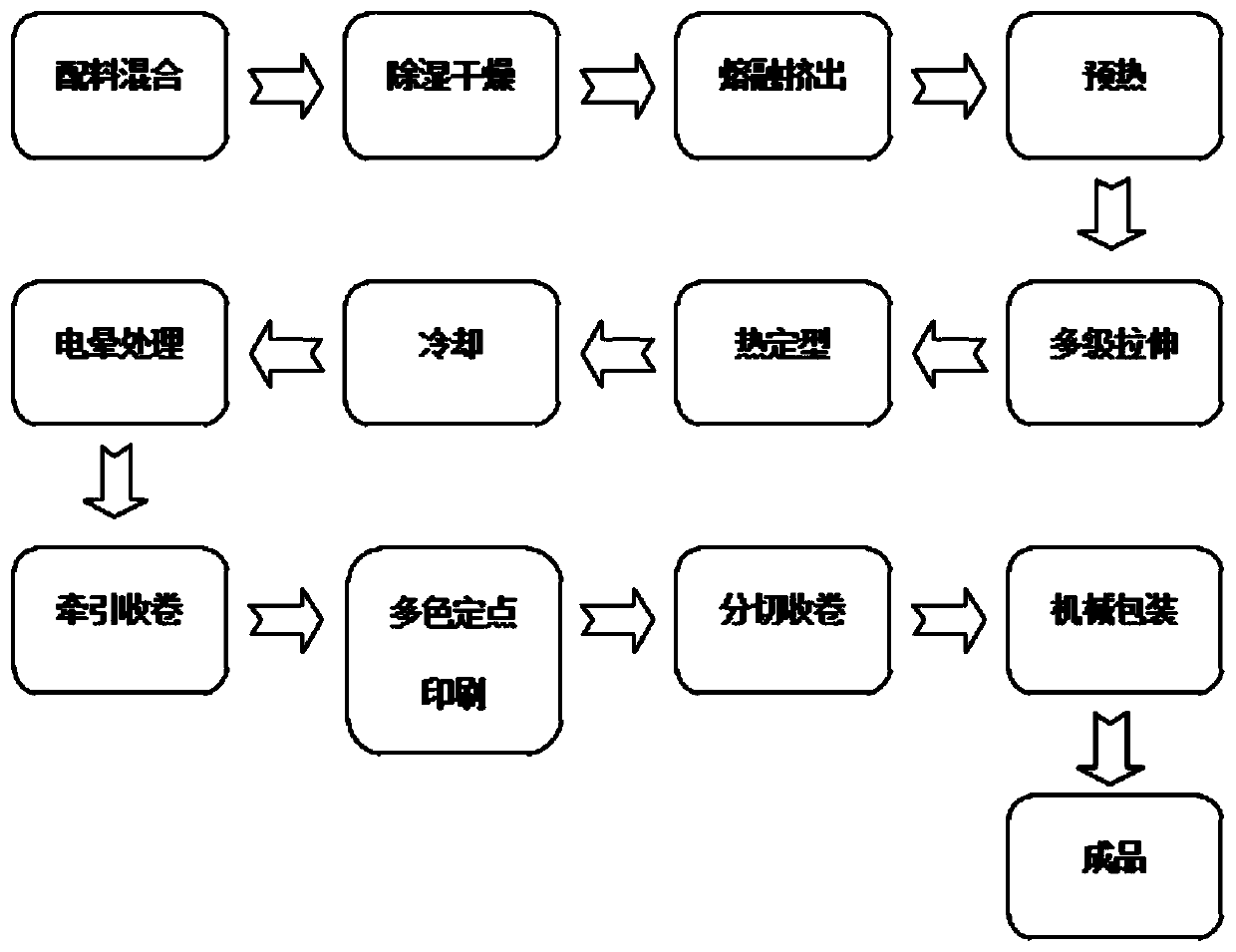

[0026] The preparation method of the bottom film comprises the following steps:

[0027] (1) Mixing of ingredients: take nano-scale heavy CaCO 3 , metallocene polyolefin mLLDPE and polyethylene are mixed, sent to the mixer, and stirred evenly;

[0028] (2) Dehumidification and drying: the mixture is placed in a dehumidification dryer for drying, and the drying temperature is set to 90°C;

[0029] (3) Melt extrusion: The dried particles are placed in a screw extruder for melt extrusion. During this period, an 800-mesh emery and a large casting rubber roller with excellent cooling effect are used, and appropriate cooling water temperature and pressure are used. , so that the high temperature molten mate...

Embodiment 2

[0035] A skin-friendly, extremely thin, highly breathable and zero-leakage bottom film, which is composed of the following raw materials in weight percentages:

[0036] Nanoscale heavy CaCO 3 50%, metallocene polyolefin mLLDPE 15%, and the rest is low density polyethylene.

[0037] The preparation method of the bottom film comprises the following steps:

[0038] (1) Mixing of ingredients: take nano-scale heavy CaCO 3 , metallocene polyolefin mLLDPE and polyethylene are mixed, sent to the mixer, and stirred evenly;

[0039] (2) Dehumidification and drying: the mixture is placed in a dehumidification dryer for drying, and the drying temperature is set to 85°C;

[0040] (3) Melt extrusion: The dried particles are placed in a screw extruder for melt extrusion. During this period, an 800-mesh emery and a large casting rubber roller with excellent cooling effect are used, and appropriate cooling water temperature and pressure are used. , so that the high temperature molten mate...

Embodiment 3

[0046] A skin-friendly, extremely thin, highly breathable and zero-leakage bottom film, which is composed of the following raw materials in weight percentages:

[0047] Nanoscale heavy CaCO 3 30%, metallocene polyolefin mLLDPE 10%, and the rest is low density polyethylene.

[0048] The preparation method of the bottom film comprises the following steps:

[0049] (1) Mixing of ingredients: take nano-scale heavy CaCO 3 , metallocene polyolefin mLLDPE and polyethylene are mixed, sent to the mixer, and stirred evenly;

[0050] (2) Dehumidification and drying: the mixture is placed in a dehumidification dryer for drying, and the drying temperature is set to 100°C;

[0051] (3) Melt extrusion: The dried particles are placed in a screw extruder for melt extrusion. During the process, an 800-mesh emery and a large casting rubber roller with excellent cooling effect are used, and the appropriate cooling water temperature and pressure are used. , so that the high temperature molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com