Dark blue thermal activation delayed fluorescence material and production method thereof as well as electroluminescent device

A technology of thermally activated delayed and fluorescent materials, applied in chemical instruments and methods, luminescent materials, electro-solid devices, etc. The effect of the small dark blue emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

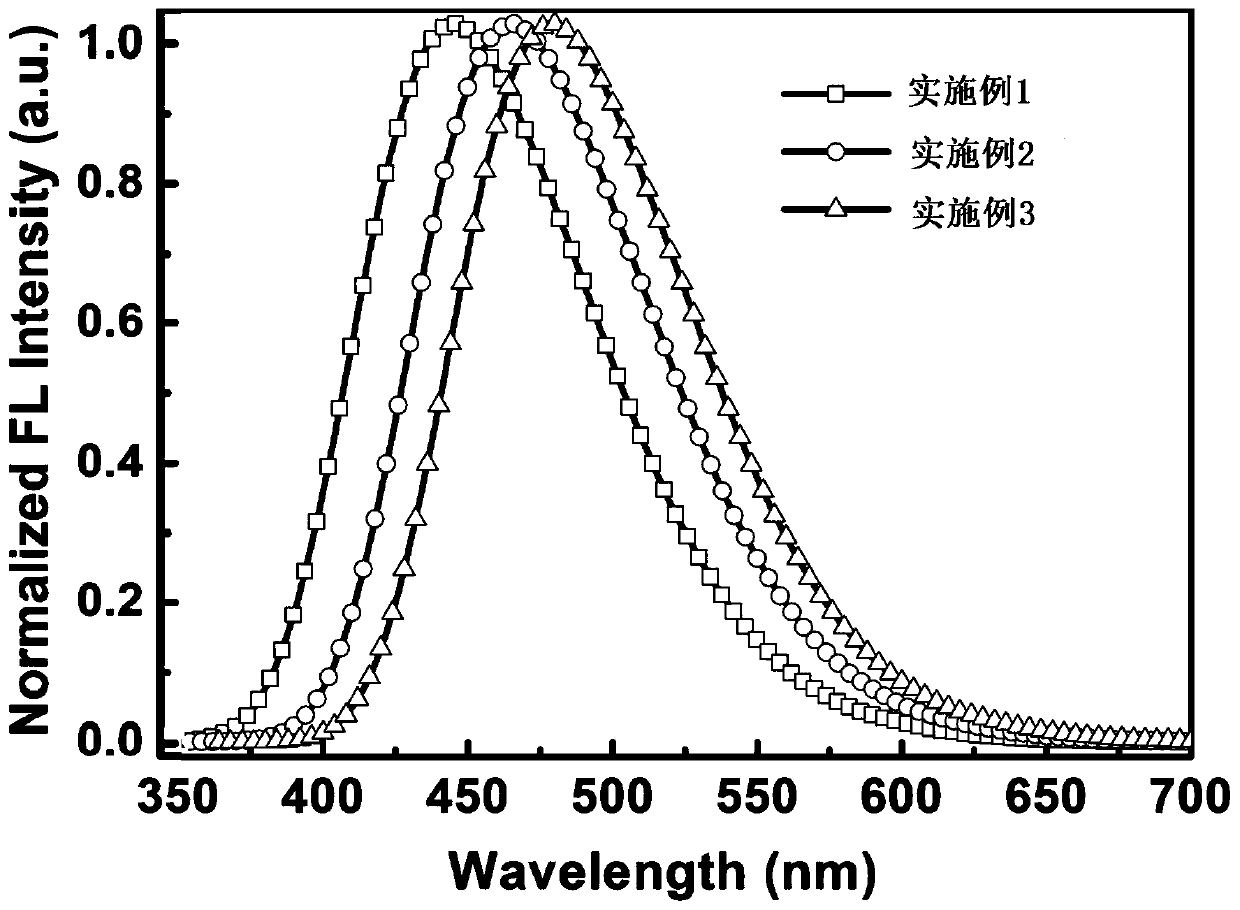

Embodiment 1

[0046]

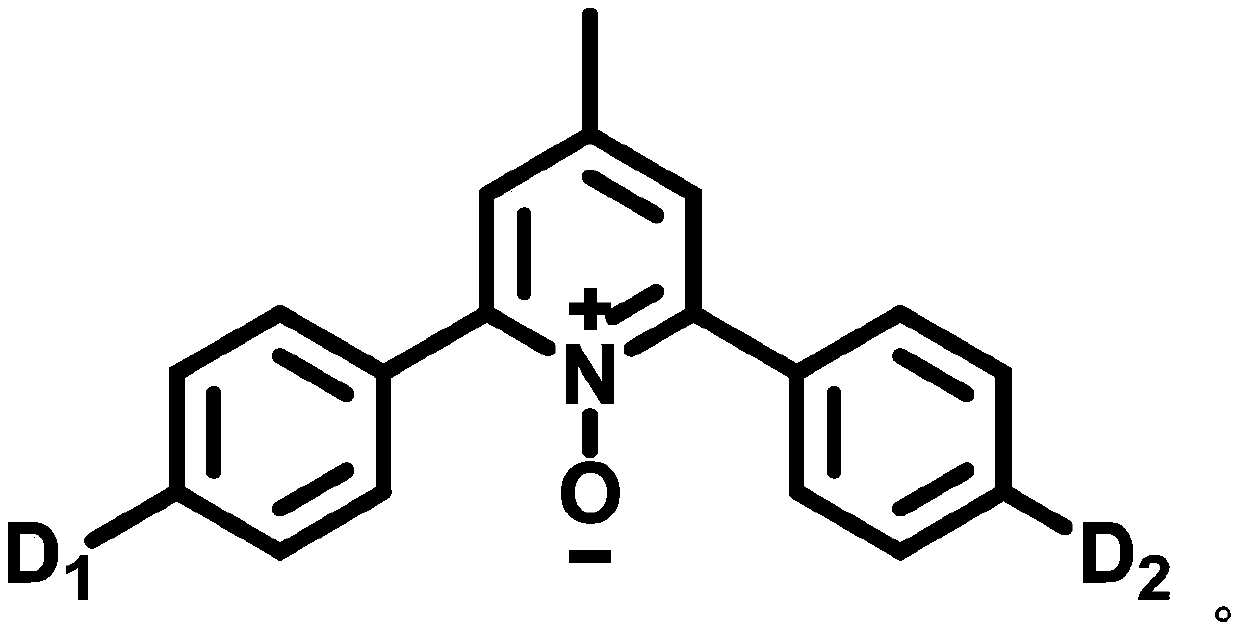

[0047] The specific steps of synthesizing the dark blue thermally activated delayed fluorescent material as formula (1) are as follows:

[0048] The first mixed solution preparation step, wherein, in this implementation, the raw material of the first electron-donating group (4-carbazolephenylboronic acid, 2.87g, 10mmol) and 2,-6-dibromo-4-picoline nitrogen oxide (2.67g, 10mmol) and catalysts (K2CO3, 2.76g, 20mmol and Pd(PPh3)4, 0.575g, 0.5mmol) were placed in the reaction vessel, pumped through three times, and injected with deoxygenated acetonitrile under argon atmosphere. Glyme (100ml), followed by reflux reaction at 85°C for 12 hours to obtain the first mixed solution, which included 4-carbazolephenylboronic acid and 2,-6-dibromo- The intermediate (2-bromo-4-methyl-6-(4-carbazolephenyl)-pyridine nitroxide) formed by the reaction of 4-methylpyridine nitroxide.

[0049] In the first extraction step, the first mixed solution was cooled to room temperature and pour...

Embodiment 2

[0060]

[0061] The specific steps of synthesizing the dark blue thermally activated delayed fluorescent material as formula (2) are as follows:

[0062] The first mixed solution preparation step, wherein, in this implementation, the raw material of the first electron-donating group (4-(3,6-dimethylcarbazole)-phenylboronic acid, 3.15g, 10mmol) and 2,-6-di Bromo-4-picoline nitrogen oxide (2.67g, 10mmol) and catalyst (K2CO3, 2.76g, 20mmol and Pd(PPh3)4, 0.575g, 0.5mmol) were placed in the reaction vessel, pumped through three times, under argon Ethylene glycol dimethyl ether (100ml) that had been deoxygenated in advance was injected under air atmosphere, and then reflux reaction was carried out at 85 degrees Celsius for 12 hours to obtain the first mixed solution, which included 4-(3, The intermediate (2-bromo-4-methyl-6-(4-(3 ,6-Dimethylcarbazole)-phenyl)-pyridine nitroxide).

[0063] In the first extraction step, the first mixed solution was cooled to room temperature and...

Embodiment 3

[0074]

[0075] The specific steps of synthesizing the dark blue thermally activated delayed fluorescent material as formula (3) are as follows:

[0076] The first mixed solution preparation step, wherein, in this implementation, the raw material of the first electron-donating group (4-(3,6-diphenylcarbazole)-phenylboronic acid, 4.39g, 10mmol) and 2,-6-bis Bromo-4-picoline nitrogen oxide (2.67g, 10mmol) and catalyst (K2CO3, 2.76g, 20mmol and Pd(PPh3)4, 0.575g, 0.5mmol) were placed in the reaction vessel, pumped through three times, under argon Ethylene glycol dimethyl ether (100ml) that had been deoxygenated in advance was injected under air atmosphere, and then reflux reaction was carried out at 85 degrees Celsius for 12 hours to obtain the first mixed solution, which included 4-(3, The intermediate (2-bromo-4-methyl-6-(4-(3 ,6-Dimethylcarbazole)-phenyl)-pyridine nitroxide).

[0077]In the first extraction step, the first mixed solution was cooled to room temperature and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com