Slotting device for road construction

A technology for road construction and underframe, applied in the field of road construction grooving devices, can solve the problems of large energy consumption, inflexible adjustment, unsatisfactory groove depth, etc., and achieves the effect of avoiding height adjustment and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

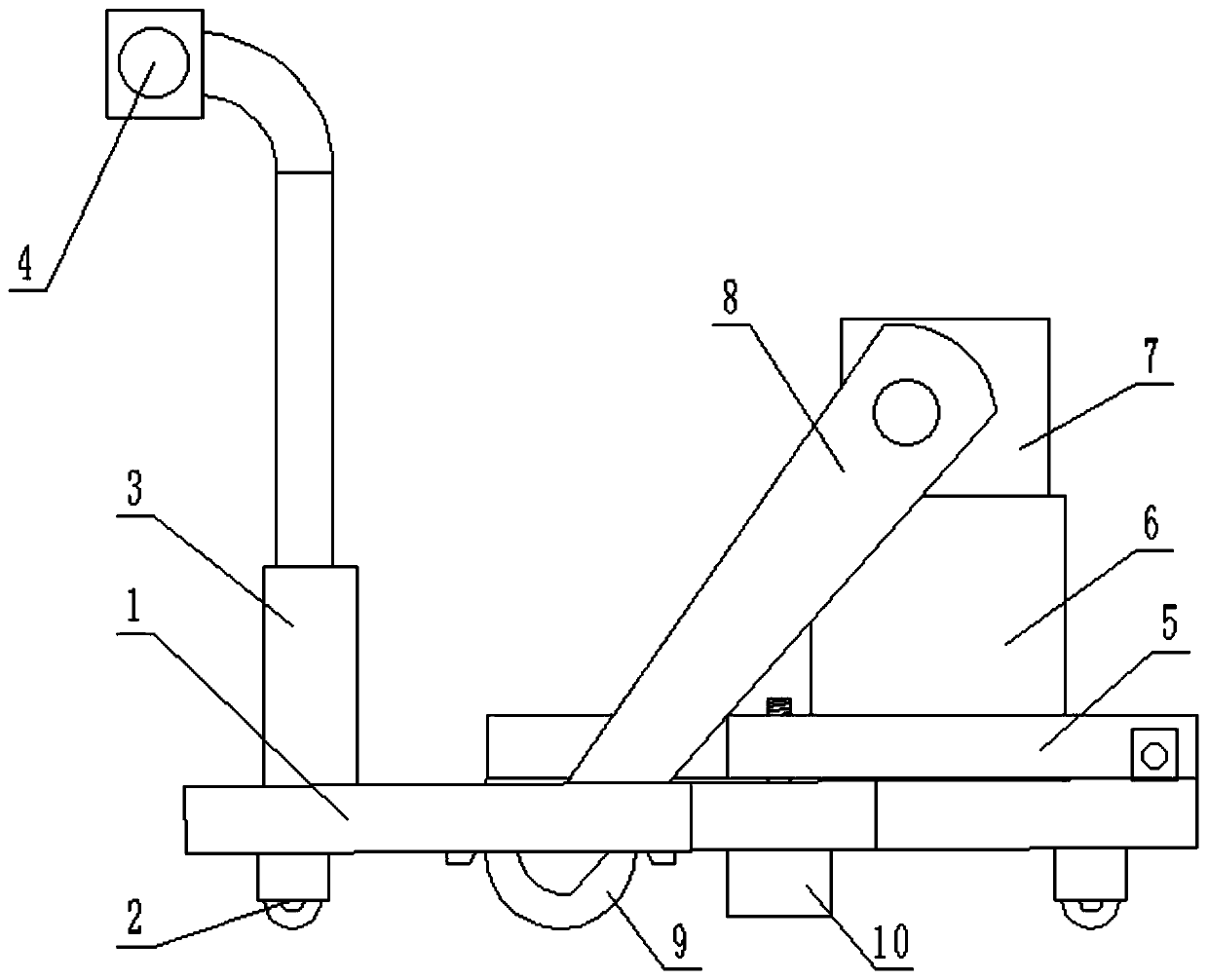

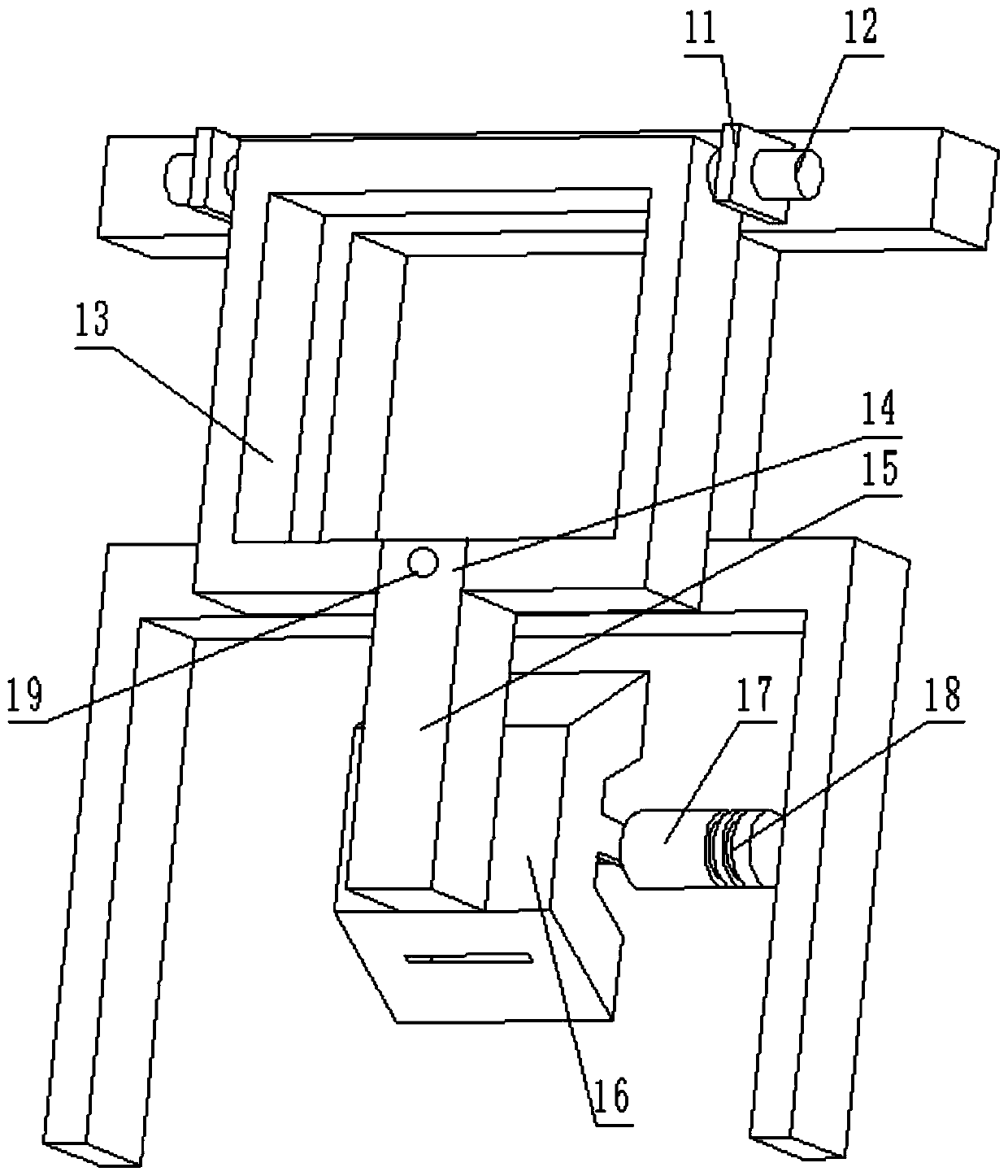

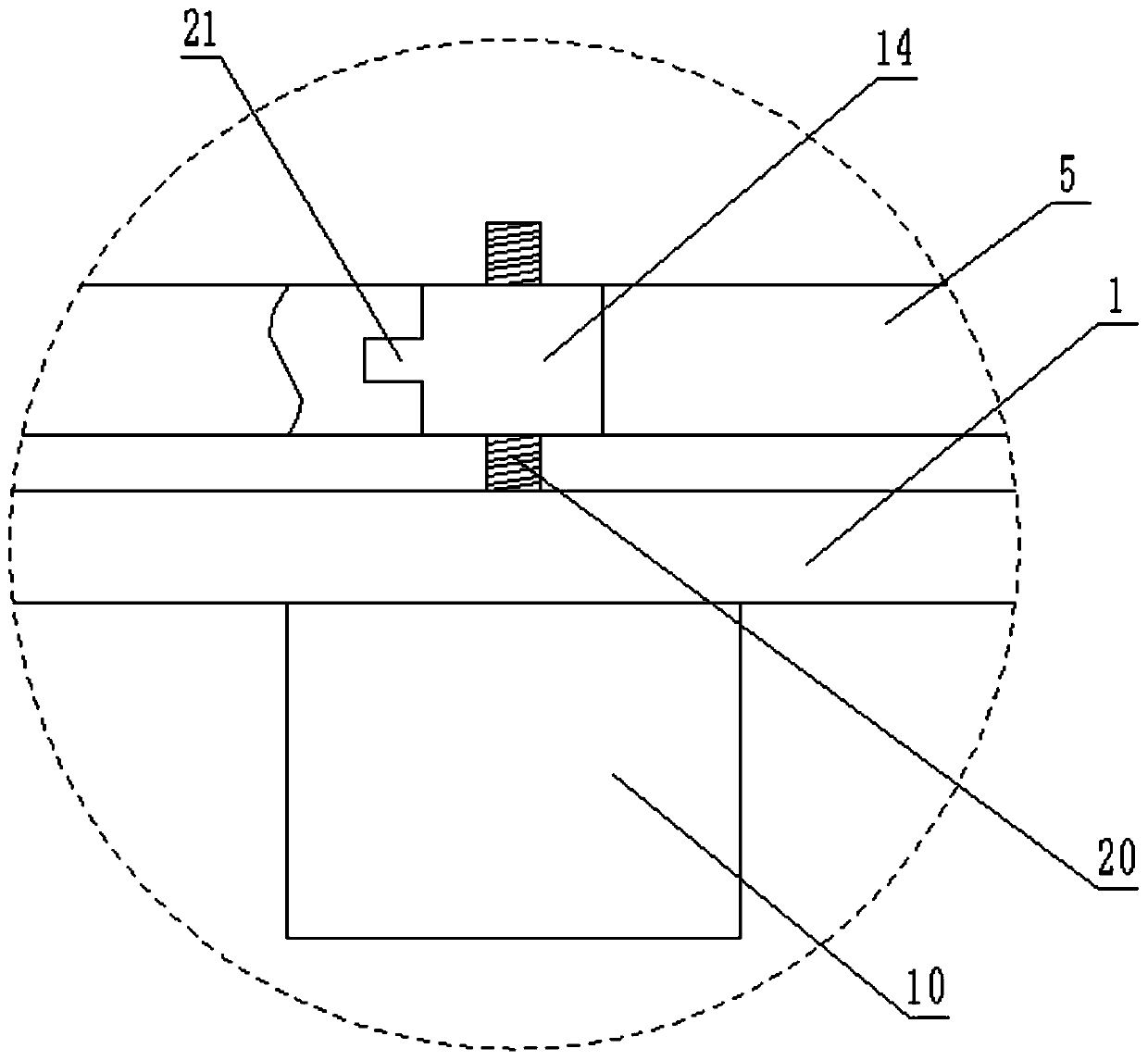

[0020] see Figure 1-3 , a road construction slotting device, comprising an underframe 1, the underframe 1 is a metal rod frame, the bottom of the underframe 1 has moving wheels 2 distributed in a matrix, and a vertical frame 3 is arranged at the end of the top surface of the underframe 1, and the vertical The top of the frame 3 has a handle 4 for pushing the device to move as a whole, and a turret 5 connected to it in rotation is also provided above the underframe 1. The turret 5 includes a supporting frame 13, a limit rotating rod 14 and a mounting rod 15, which limit The rotation of the position turning rod 14 is located in the center of one side of the supporting frame 13, and the installation rod 15 is fixedly connected with the limit rotating rod 14. On the supporting frame 13, an oil tank 6 and a drive motor 7 are successively superimposed, and the oil tank 6 is used for Drive motor 7 work provides power, and the output shaft of drive motor 7 is positioned at its side a...

Embodiment 2

[0024] On the basis of embodiment 1, in order to avoid damage and ensure the service life of the device, a transmission belt box 8 is provided on the side of the drive motor 7, the lower end of the transmission belt box 8 is fixed on the outside of the knife box 16, and the transmission belt box 8 wraps the transmission belt in its entirety inside, to avoid possible damage to the drive belt exposed to the outside for a long time.

Embodiment 3

[0026] On the basis of Embodiment 1, in order to facilitate the control operation, a controller is provided on the top of the vertical frame 3, and the controller is electrically connected with the rotating motor 10 and the driving motor 7. The controller has a control button, and its internal chip can be Using existing chips such as A3952SB, etc., there is no specific limitation here, while the device is being pushed, the opening and closing of the slotting work and the adjustment of the slotting depth can be performed, which is very convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com