A two-dimensional reversing valve with cover plate cartridge type based on flexible hinge type compression torsion coupling

A technology of pressure-torsion coupling and flexible hinge, which is applied in the direction of fluid pressure actuation device, valve operation/release device, multi-way valve, etc., can solve the problems of complex hydraulic system, difficult maintenance, single function, etc. The effect of good dynamic response, simple structure and high displacement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the various embodiments mentioned herein are only exemplary and do not limit the scope of the patent rights. Considering the convenience of the mechanical / electromechanical structures described in the various embodiments of this patent, general references to "upper", "lower", "left" or "right" are indicated according to the directions or positions depicted in the drawings. The views of these mechanical / electromechanical structures shown in each figure are best seen in order to better illustrate the various embodiments, and it is also possible to depict each detail individually. Sometimes, an orientation "front" or "rear" refers to the point of view from which the drawings are viewed to define the arrangement of these components.

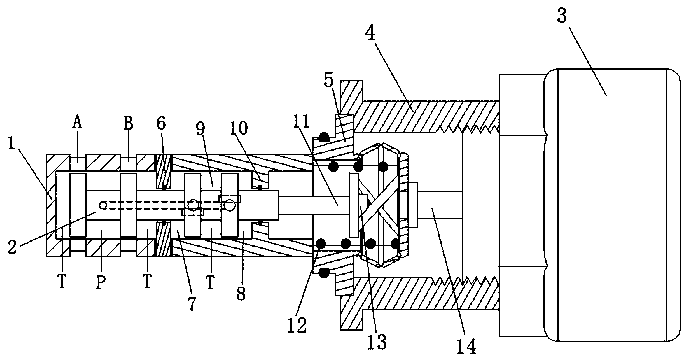

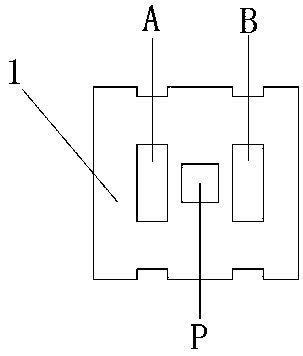

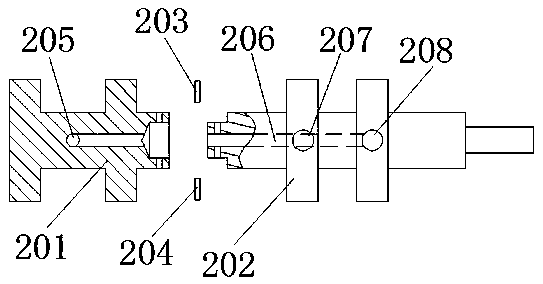

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , The present invention includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com