Rubber fatigue tensile test bench and rubber fatigue tensile test method

A tensile test and rubber technology, applied in the direction of applying stable tension/pressure to test the strength of materials, to achieve the effects of strong controllability, reduced inertial impact, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

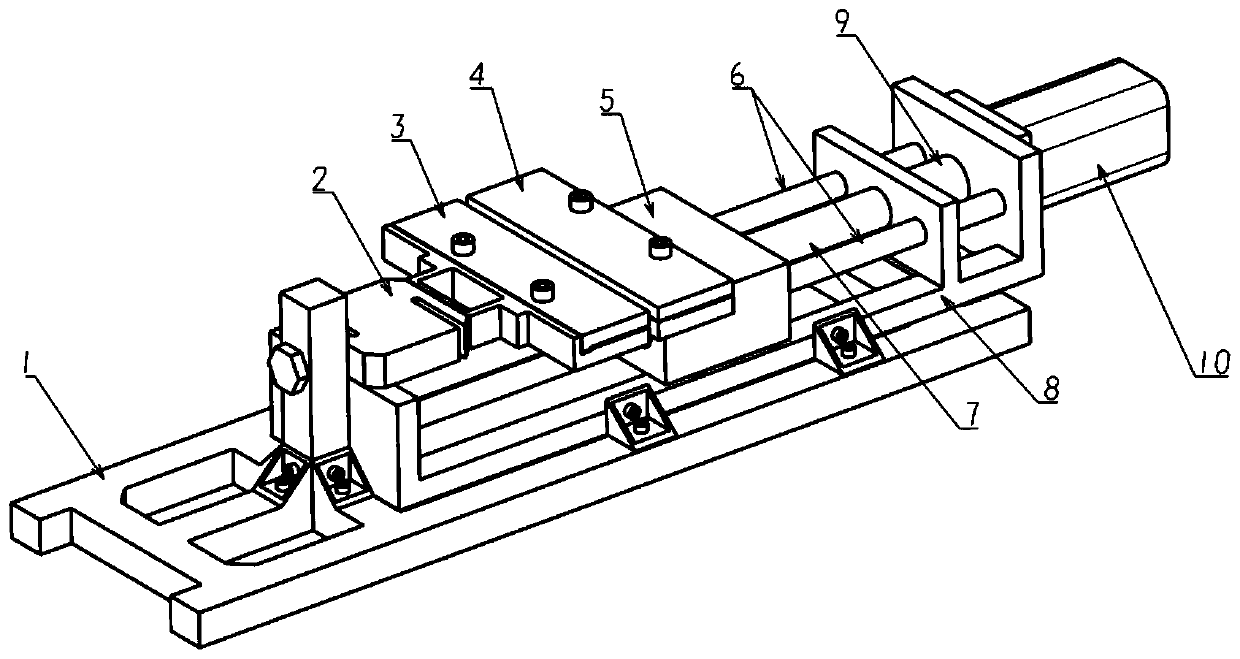

[0028] First, the specific structure of the rubber tensile test bench of the present invention will be described in detail below.

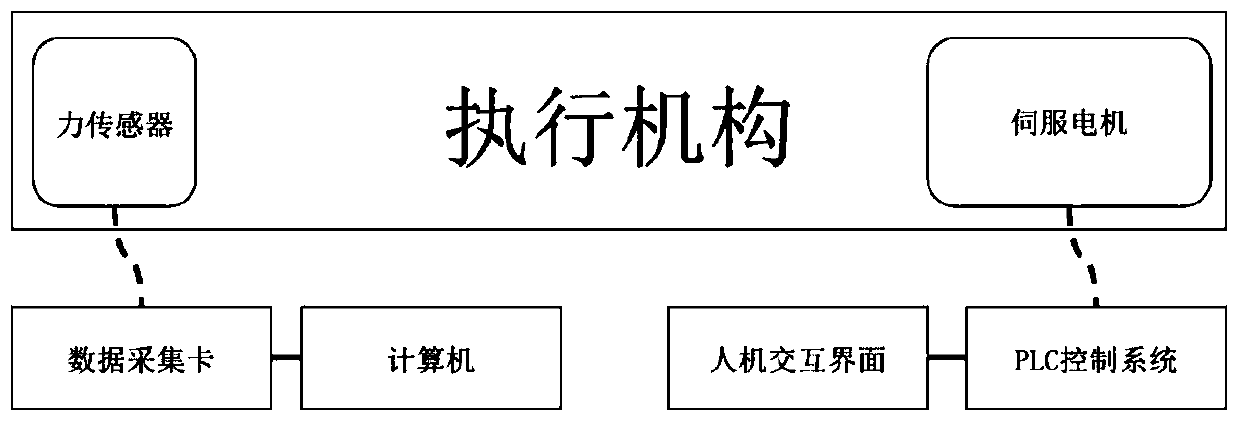

[0029] see figure 1 , in an embodiment of the present invention, a rubber fatigue tensile test bench is composed of three parts: an actuator, a data acquisition system, and a control system. The actuator includes an overall fixing frame 1, a force sensor 2, a left clamp 3, and a right clamp 4. Sliding table 5, support rod 6, lead screw 7, sliding table base 8, coupling 9, servo motor 10; the left clamp 3 is installed on the force sensor 2 through a fixed bracket and bolts, and the force sensor 2 is mounted on the force sensor 2 through the bolts Installed on the sensor installation column of the overall fixed frame 1; the right fixture 4 is installed on the slide table 5 through bolts, and a threaded hole is processed in the middle of the slide table 5, and there is a light hole on each side of the threaded hole; the slide table 5 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com