Design method of honeycomb-microperforated film composite structure

A design method and composite structure technology, applied in the direction of sound-emitting devices, instruments, layered products, etc., can solve the problems that it is difficult to adjust the sound absorption coefficient and sound absorption frequency band of the composite structure at any time, and change the environmental noise, and achieve engineering manufacturing Easy, wide-ranging application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings. see Figure 2 to Figure 6 .

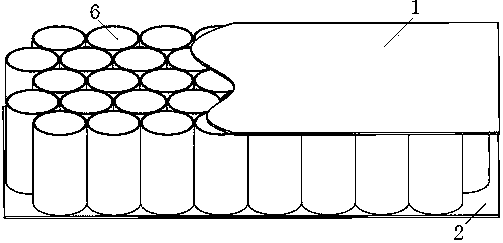

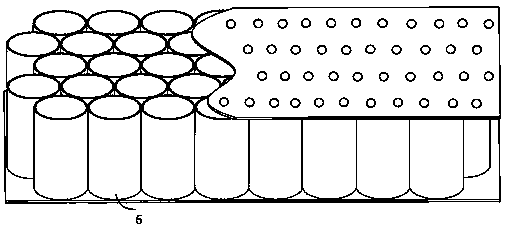

[0037] In order to obtain better sound-absorbing properties of the honeycomb sandwich structure, the present invention considers that the upper surface plate 1 is made into a micro-perforated plate, such as figure 2 shown.

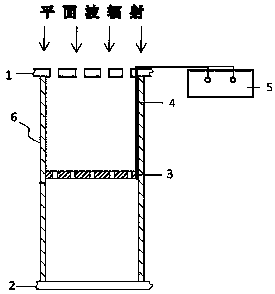

[0038] in such as figure 2 Take out a honeycomb core 6 in the shown honeycomb sandwich structure, and add a piece inside the honeycomb core 6 Figure 5 As shown in the DE micro-perforated film 3, since the size of the DE micro-perforated film 3 installed in the honeycomb core is relatively small, regardless of the additional acoustic impedance caused by the vibration of the film itself, the upper and lower sides of the DE micro-perforated film 3 are first plated with a certain thickness of The conductive electrode is then connected with an external voltage generating terminal 5 by a lead wire 4 . Wherein, the DE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com