Cable and feed body connecting method suitable for deep well type grounding electrode

A connection method and grounding electrode technology, which can be used in connection, dust/splash/leakage/waterproof/fireproof connection, connection contact material, etc., can solve problems such as protection failure, avoid deformation, reduce welding The effect of medicinal doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

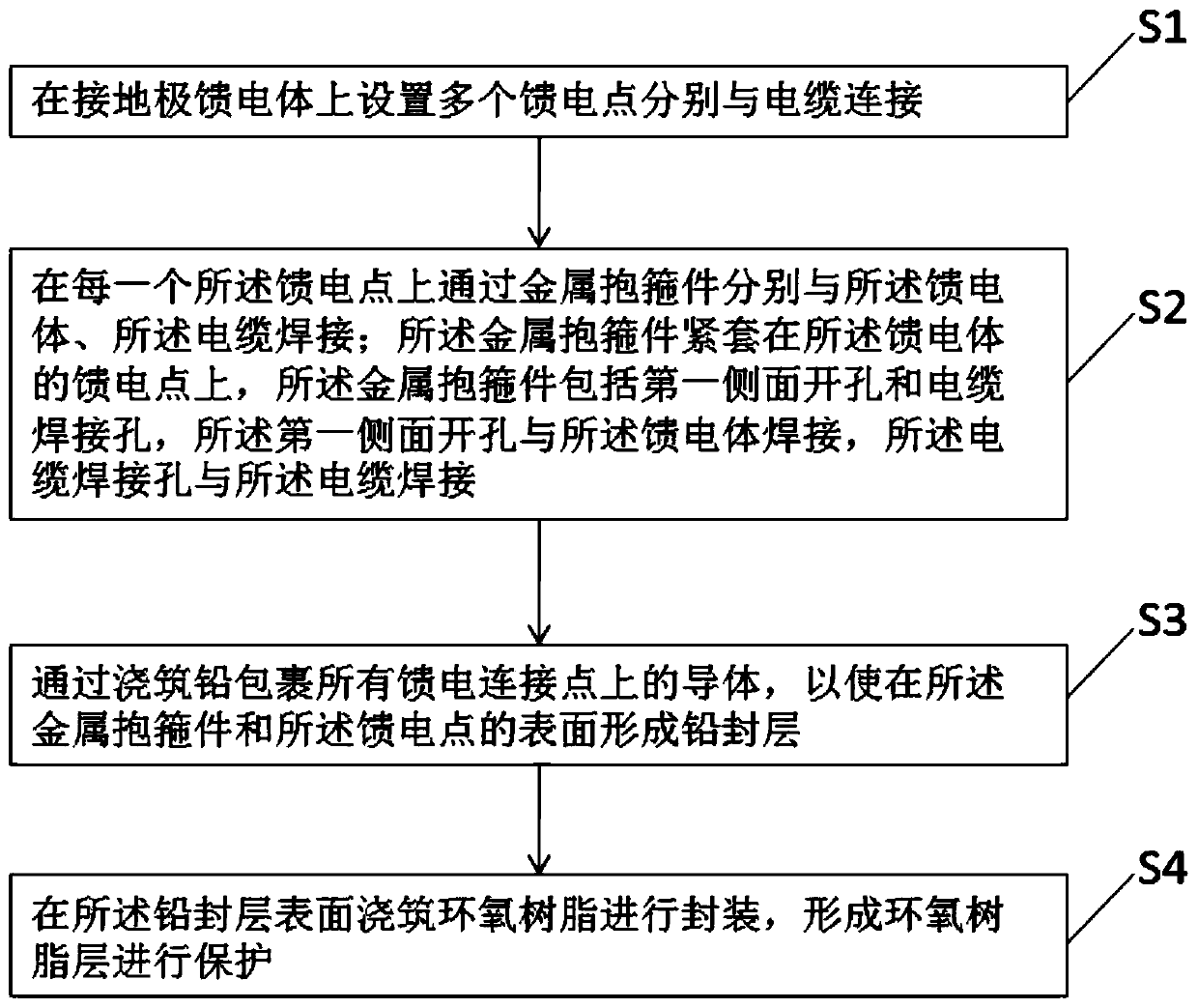

[0032] Please refer to Figure 1-Figure 4 , the preferred embodiment of the present invention provides a method for connecting cables and power feeders suitable for deep well type grounding electrodes, including:

[0033] S1, set multiple feed points on the ground electrode feed body to connect with cables respectively;

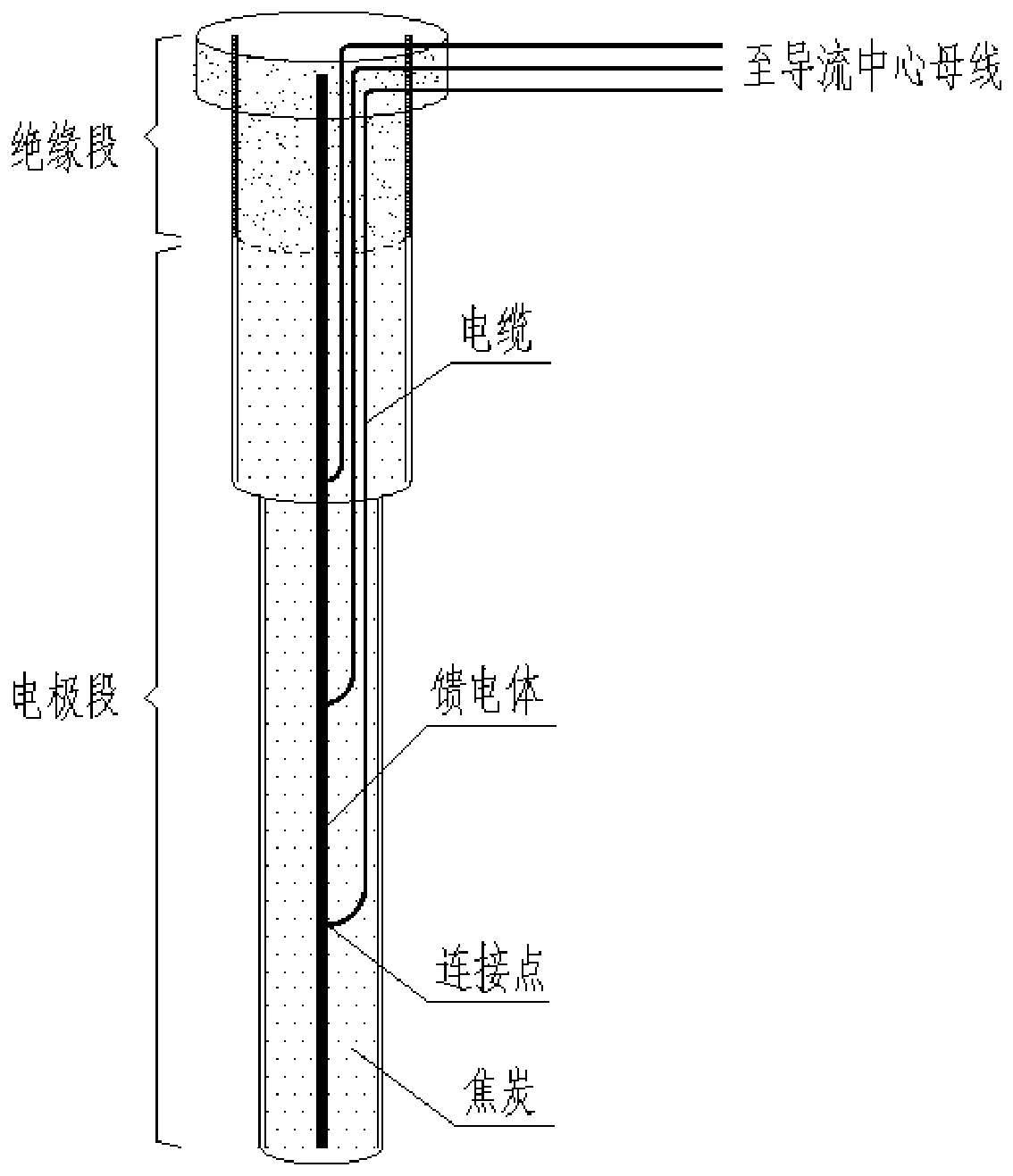

[0034] The deep well electrode is mainly composed of feeder, coke filler and wall casing, and the diversion cable is vertically installed in the coke filling layer to connect the diversion center busbar and the electrode feeder. In order to ensure the reliability of current injection, the way of cable independent conduction is usually adopted, that is, independent conduction cables are connected to different depth positions of the feed body in the effective electrode section.

[0035] In view of the current drilling technology and capabilities, the drilling machine that is more suitable for the electrode depth requirements is the roller cone drilling machine...

Embodiment 2

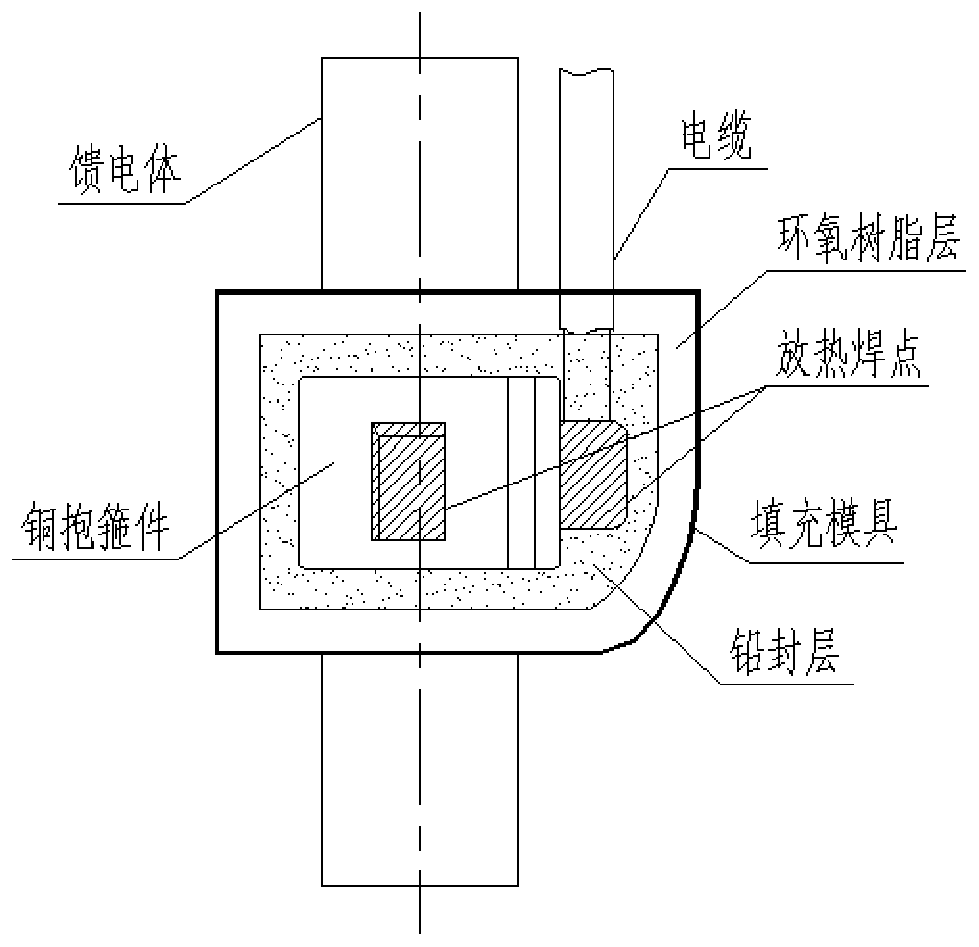

[0042] Please refer to Figure 5 , on the basis of the first embodiment above, further comprising: S5, after pouring is completed, the setting mold used when filling the epoxy resin is lowered and installed together, so that a filling mold layer is formed on the surface of the epoxy resin layer. In this embodiment, the material of the filling mold layer is fiberboard. In this embodiment, the gap between the filling mold layer and the power feeder is sealed by wrapping waterproof tape.

[0043]The epoxy resin layer is easy to be damaged and cracked during the construction process. Therefore, after the pouring is completed, the shaping mold used for filling the resin should be lowered and installed together. The epoxy resin mold should be made of tough pressure-resistant materials, such as fiberboard, which can increase the environmental The compressive capacity of the epoxy resin layer. The gap between the mold and the feeder steel pipe is wound and sealed with waterproof tap...

Embodiment 3

[0045] Please refer to Figure 6-Figure 7 , on the basis of the second embodiment above, the metal hoop member further includes a second side opening, the second side opening is opposite to the first side opening, and the second side opening is opposite to the first side opening. The feed body is welded. In this embodiment, the thickness of the wall of the metal hoop where the cable welding hole is located is greater than the thickness of the rest of the wall.

[0046] Three openings are arranged on the cylinder of the copper piece. Two of the side openings can be exothermicly welded with the feed body, which is used to increase the reliability of the electrical connection between the copper parts and the power feed body; the "line-surface exothermic welding" is adopted between the diversion cable and the customized copper parts, and its The wall thickness of the copper parts used for exothermic welding is thicker, which can increase the allowable carrying capacity of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com