Insulation framework structure and stator assembly structure

A technology of insulating skeleton and stator assembly, which is applied in the direction of structural connection, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of unfavorable structure assembly, high preparation cost, and inability to disassemble, so as to achieve excellent insulation effect, Low cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An insulating skeleton structure, comprising: a stator block 71 , a first skeleton 8 , a second skeleton 9 , and a coil assembly 72 .

[0039] The stator block 71 is formed by laminating electromagnetic silicon steel sheets. The first skeleton 8 and the second skeleton 9 are formed by injection molding. The material is insulating nylon or other insulating materials, which have good strength and good insulation performance; the first skeleton 8 and the second After the skeleton 9 is bonded to the stator block 71, the coil assembly is wound; the skeleton structure ensures the insulation between the stator block 71 and the coil assembly 72; Good strength to prevent coil deformation.

[0040] The first frame 8 includes two first outer baffles 81, two first inner baffles 82, a threading slot 83, a number of first wiring slots 84, a first line retaining step 85, and a first mating female end 86 , the first pair of plug-in male ends 87, the first pair of plug-in female ends 8...

Embodiment 2

[0050] Based on the above characteristics, a set of molds can realize stator skeleton modes in three states (such as Figures 11 to 13 shown); see the table below for details:

[0051]

[0052] The advantages of the above three matching states are: less materials, stronger general purpose, and convenient inventory management.

Embodiment 3

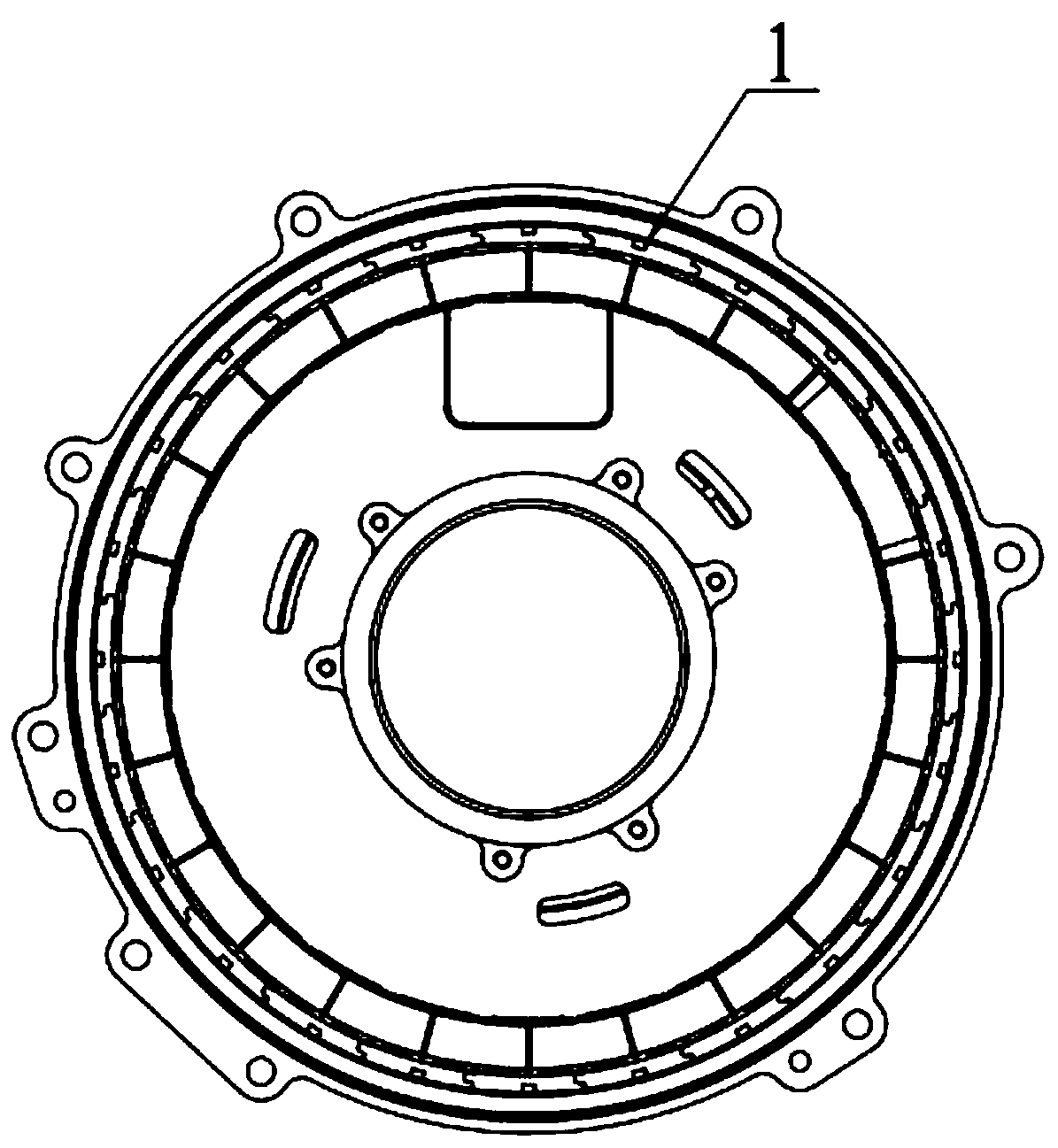

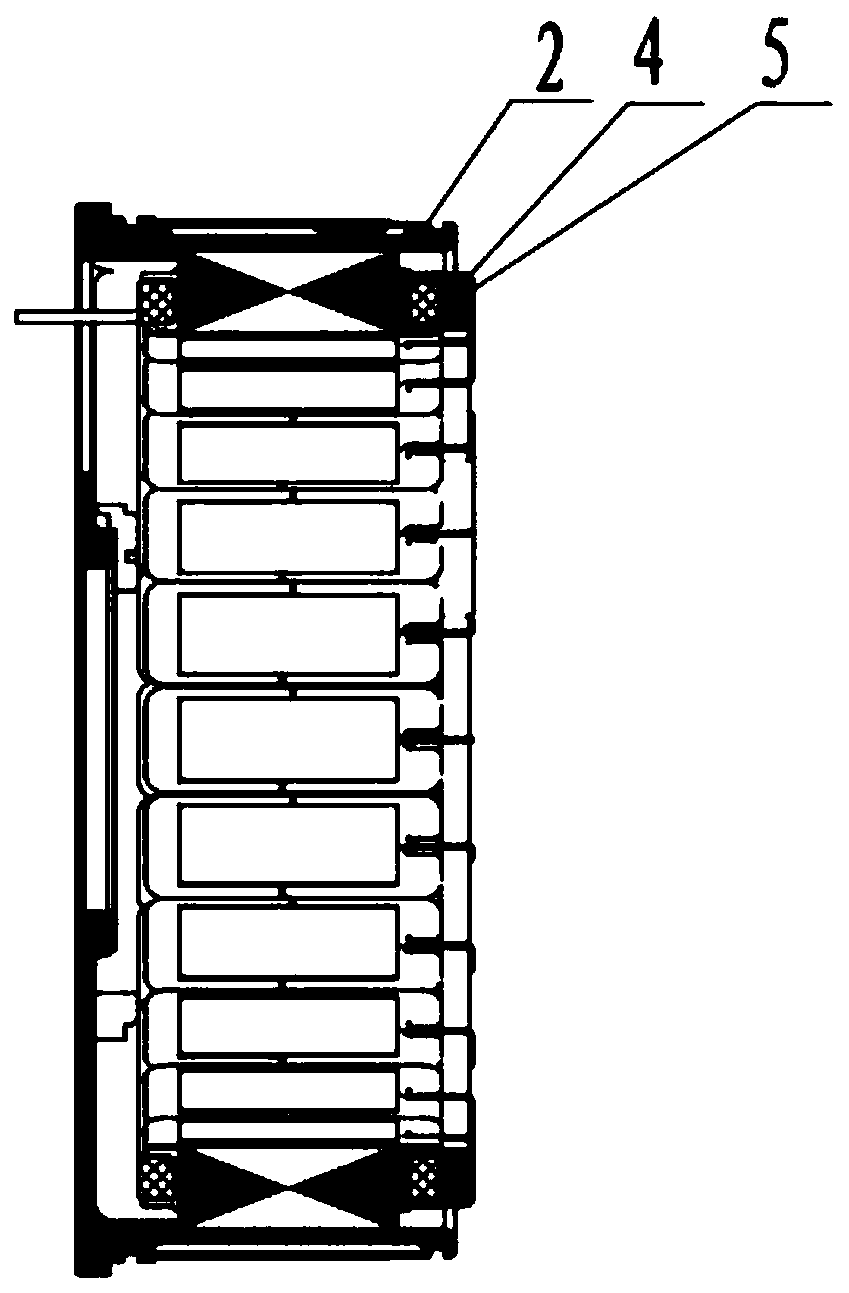

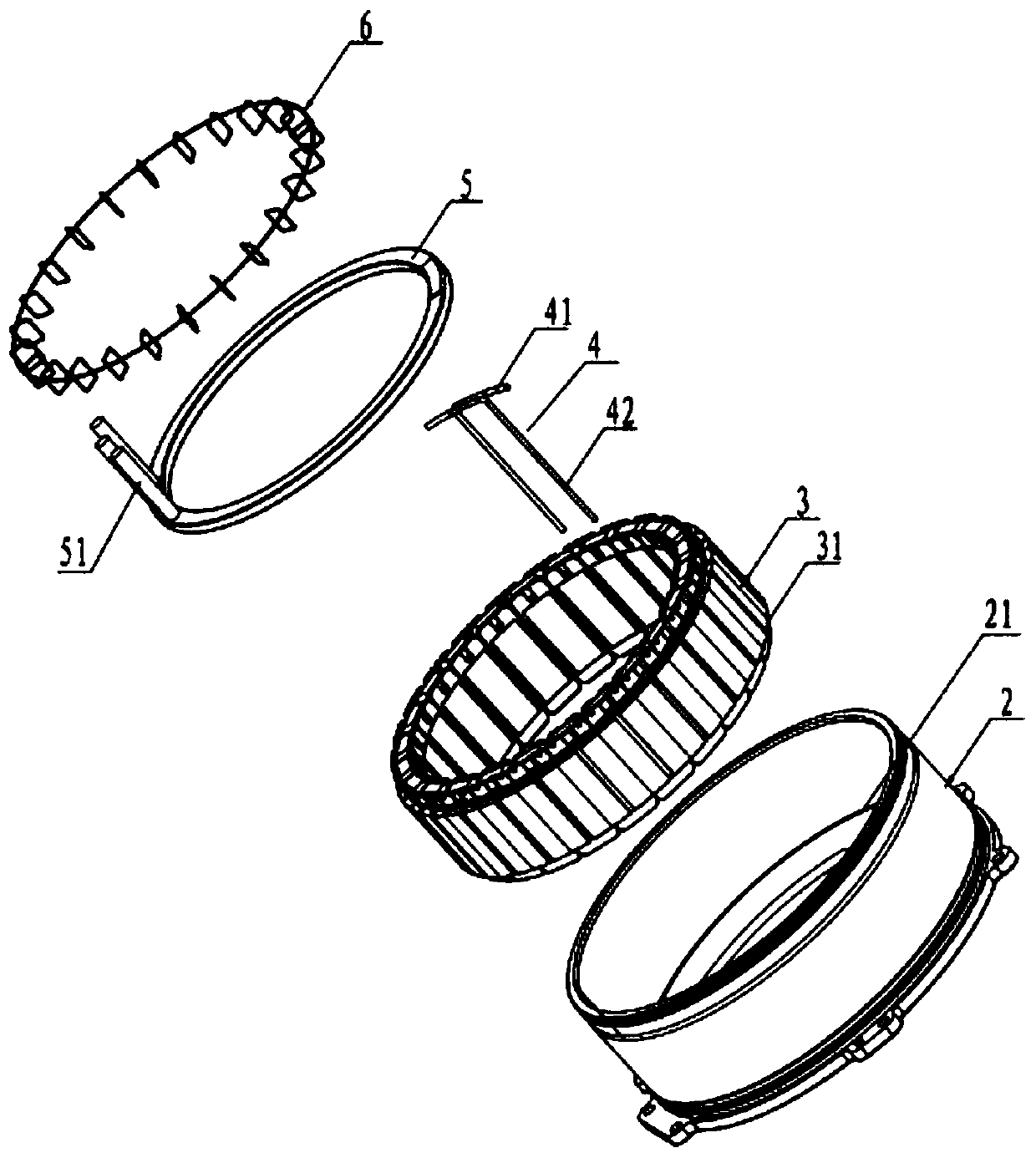

[0054] Based on the insulating skeleton structure in the above two embodiments, the present invention also particularly relates to a stator assembly structure, including a water jacket 2, a stator assembly 3, a temperature sensor 4, a coil layer 5, and a binding wire 6; the water jacket 2 and The stator assembly 3 is interference fit, the iron core end surface 21 of the water jacket 2 is axially positioned and matched with the stepped surface 31 of the stator assembly 3 , and the circumferential direction is positioned by fixing keys or tooling. The stator assembly 1 is provided with a plurality of temperature sensors 4, the temperature sensor 4 includes a temperature measuring part 41 and a wire harness end 42, and the temperature measuring part 41 is embedded in the coil layer 5 and the coil assembly 72 of the stator block assembly 7 of the stator assembly 3 Between the ends, the temperature is preferably collected at the highest point of the coil assembly 72; the wire harnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com