Circuit board structure and manufacturing method thereof

A manufacturing method and circuit board technology, which is applied to printed circuits, printed circuits, printed circuits assembled with electrical components, etc., can solve problems such as multiple costs, lower yields, and complicated manufacturing, and achieve reduced manufacturing costs and high process requirements. , the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The foregoing and other technical content, characteristics and efficacy of the present invention will be clearly presented in detail below with reference to the various embodiments of the drawings. The direction used in the following examples, such as "upper", "lower", "front", "post", "left", "right", etc., is only the direction of the additional drawings. Therefore, the direction term used is illustrated, and is not intended to limit the invention. Also, in the following examples, the same or similar components will use the same or similar reference numerals.

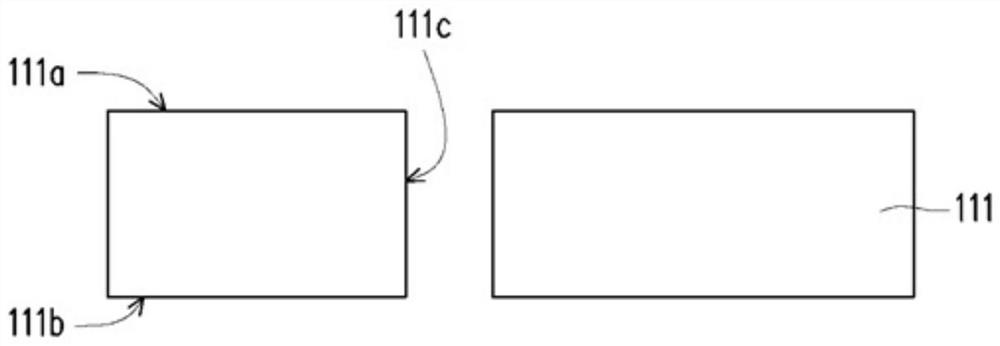

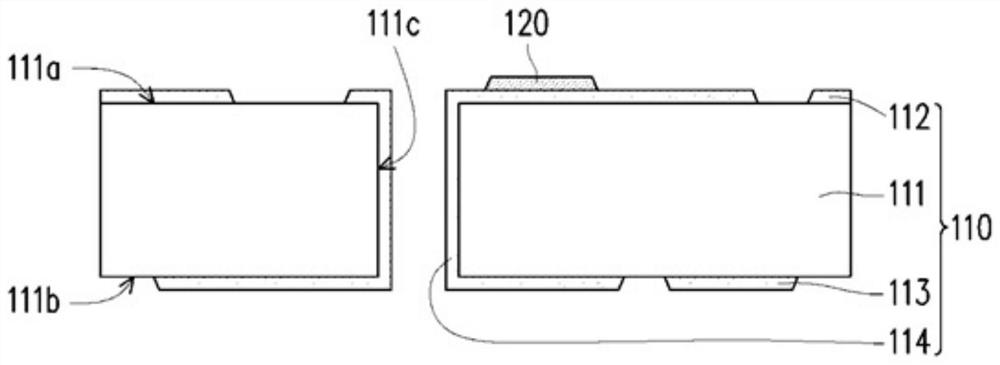

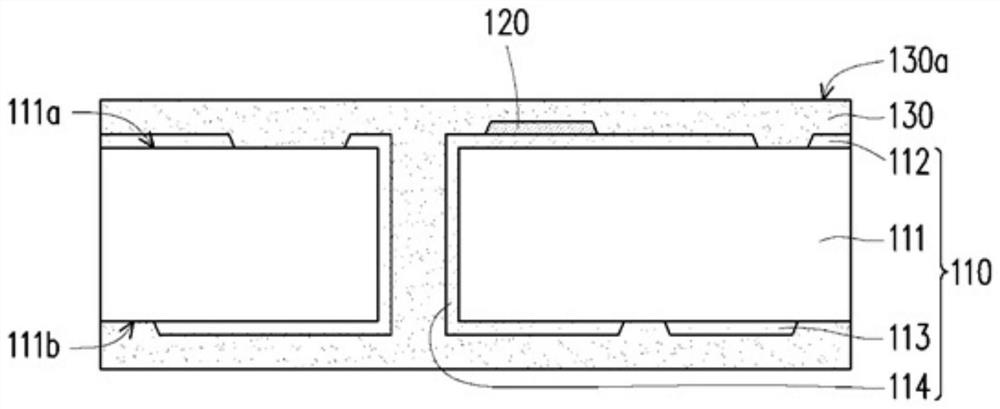

[0064] Figures 1A to 1G It is a cross-sectional view of a manufacturing process of a circuit board structure according to an embodiment of the present invention. Figure 1h Yes Figure 1G The enlarged view of the middle region R. Figure 1I Yes Figure 1G The upper view schematic of the middle region r. For the sake of clarity, Figure 1I In the middle, a portion of the die or component is omitted.

[0065] The method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com