Synthetic diamond optical elements

A technology for synthesizing diamonds and optical components, applied in optical components, optical, electrical components, etc., can solve problems such as lowering of laser-induced damage threshold, lowering of optical properties of synthetic diamond windows, beam distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

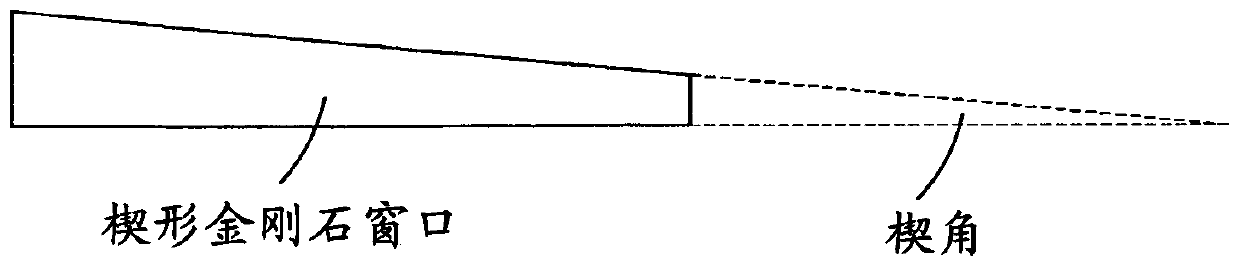

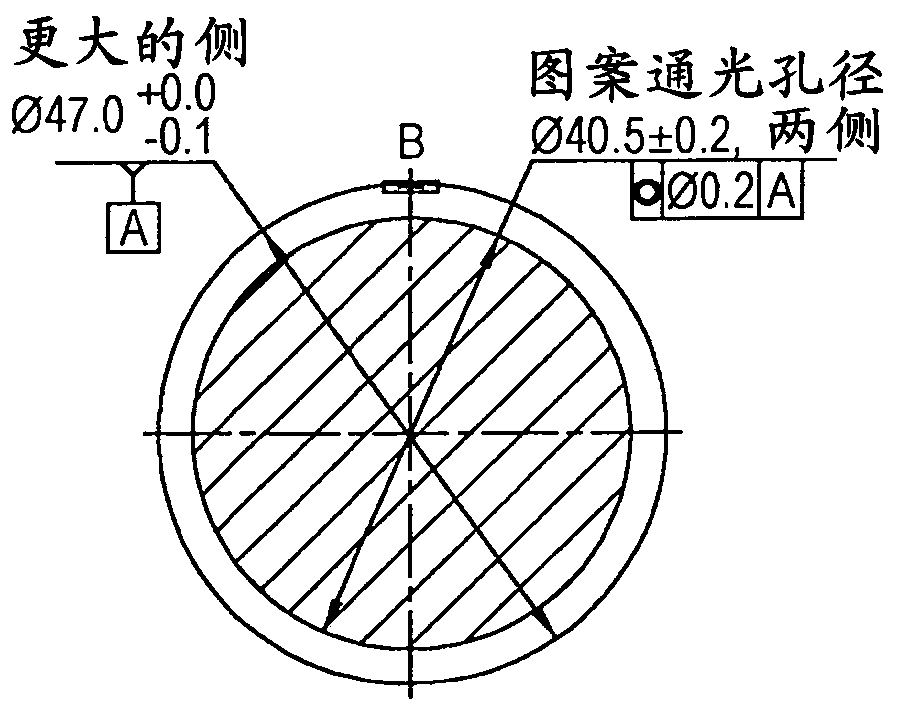

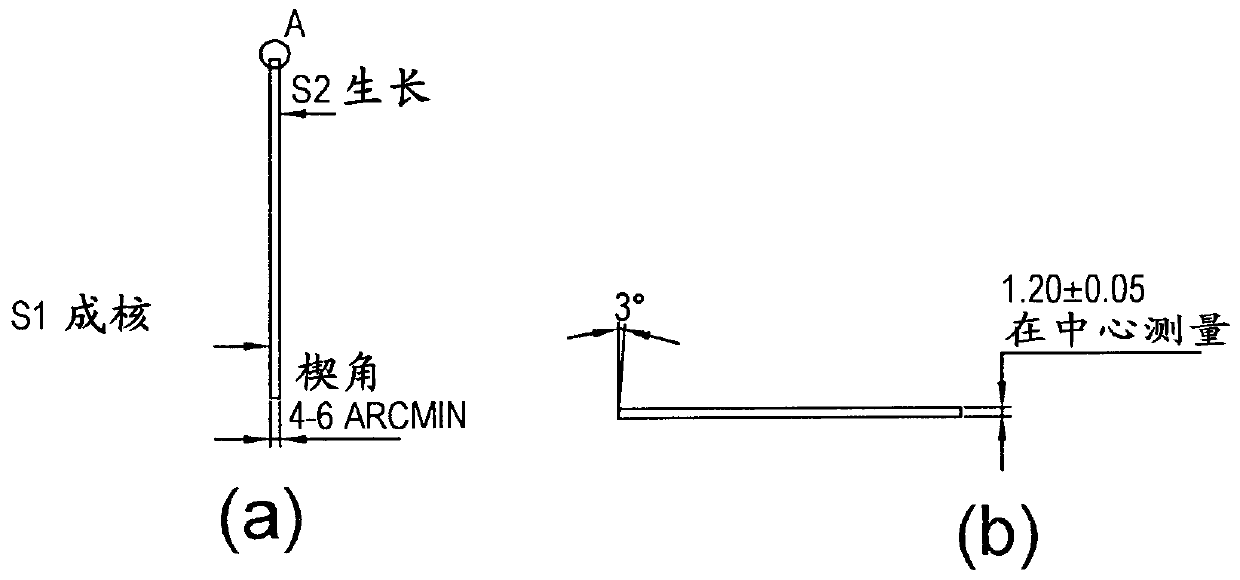

[0018] As described in the Summary of the Invention, one aspect of the present invention relates to the manufacture of an optical element comprising: a window formed from a synthetic diamond material; and an optical surface pattern formed directly in the surface of the synthetic diamond material, wherein the synthetic The window of diamond material is in the form of a wedge-shaped diamond window having non-parallel major surfaces with wedge angles defined in the range of 1 arcmin to 10°, and the optical surface pattern is formed directly on one or both of the non-parallel major surfaces. Among those.

[0019] figure 1 A schematic illustration of a wedge-shaped diamond window is shown in . Such wedge-shaped and patterned synthetic diamond windows have been found to be beneficial in reducing or eliminating beam distortion in certain laser applications, particularly in systems utilizing relatively long coherence length lasers.

[0020] Wedge and patterned diamond windows are ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com