Deodorizing device and deodorizing technology for feed processing

A technology for feed processing and odor removal, which is applied in the field of deodorization devices for feed processing. It can solve the problems of residual toxic and harmful waste gas, injury to factory workers, and difficulty in removing odors, so as to improve absorption efficiency, improve odor treatment efficiency, and remove odors. The effect of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

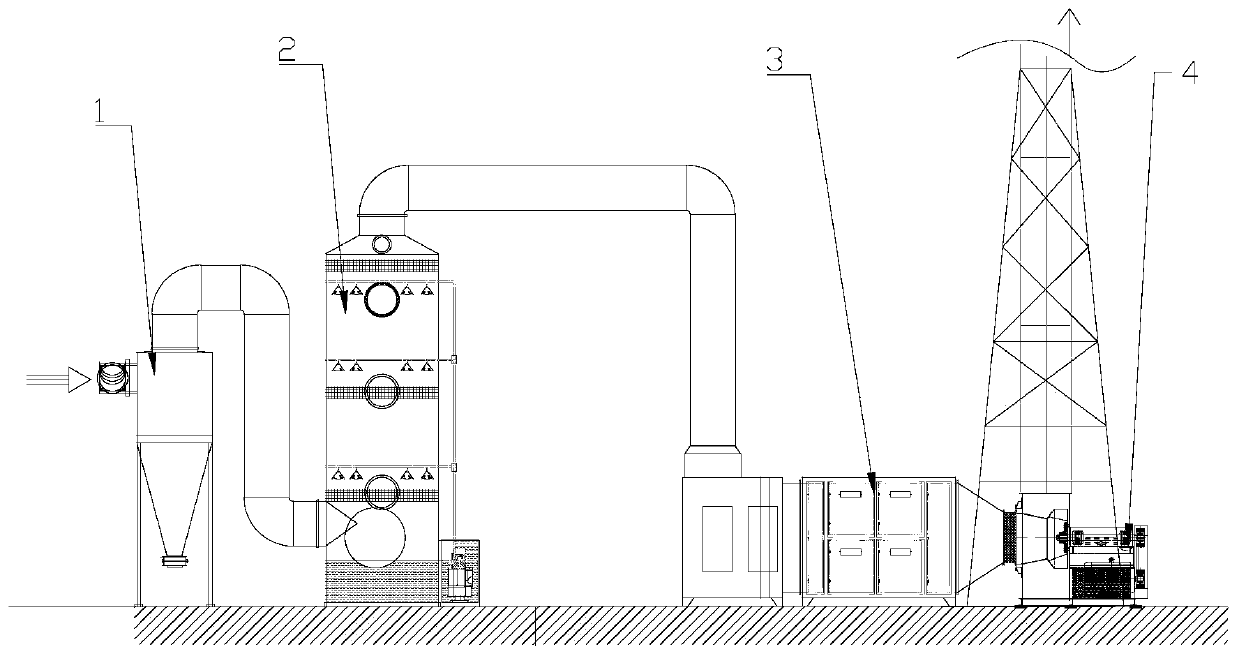

[0030] A deodorization device for feed processing, comprising an air inlet tank 1, an absorption tower 2, a UV reaction tank 3 and an emptying tower 4 connected in sequence, see figure 1 .

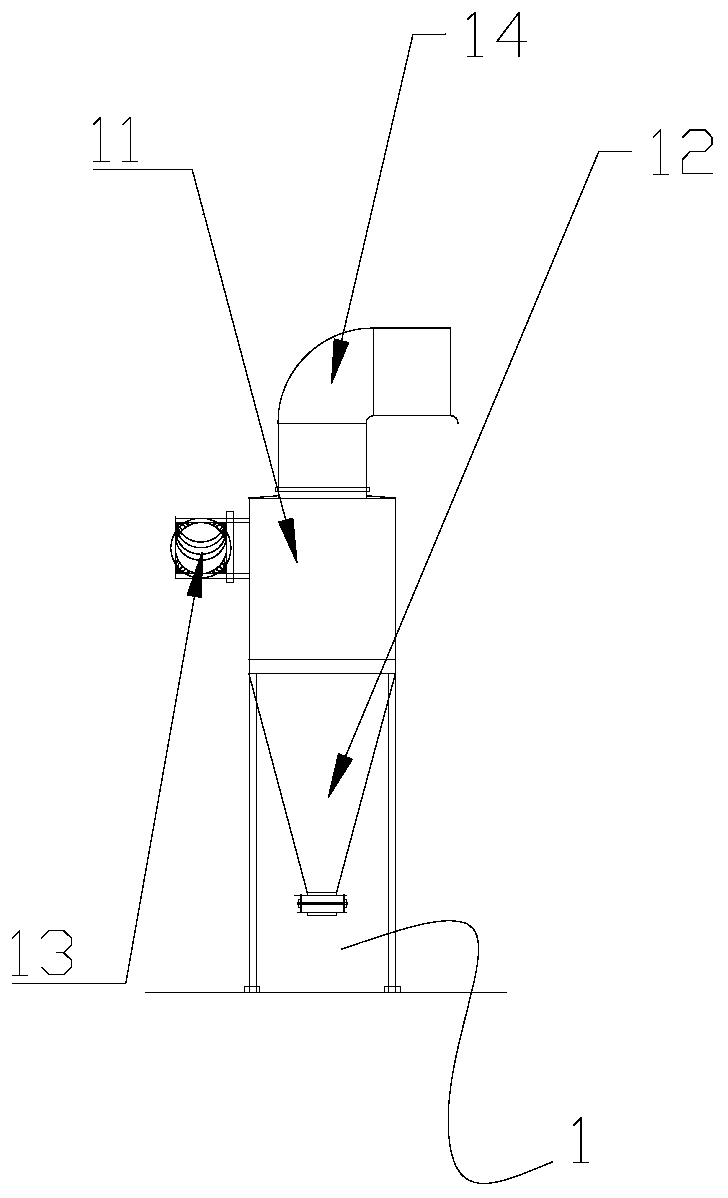

[0031] Air intake tank 1 part: including the upper bag filter 11 and the lower deposition funnel 12, the side of the bag filter 11 is provided with an inlet tank gas inlet 13, and the top of the bag filter 11 is provided with an air inlet The tank gas outlet 14, the deposition funnel 12 is used to deposit the dust generated by the bag filter 11. The intake air is firstly dedusted by the dust collector, which prevents the dust or tiny particles in the exhaust gas from entering and blocking the subsequent absorption tower and UV reactor, which significantly improves the failure of the processing device caused by dust blockage and improves the overall odor. Processing efficiency.

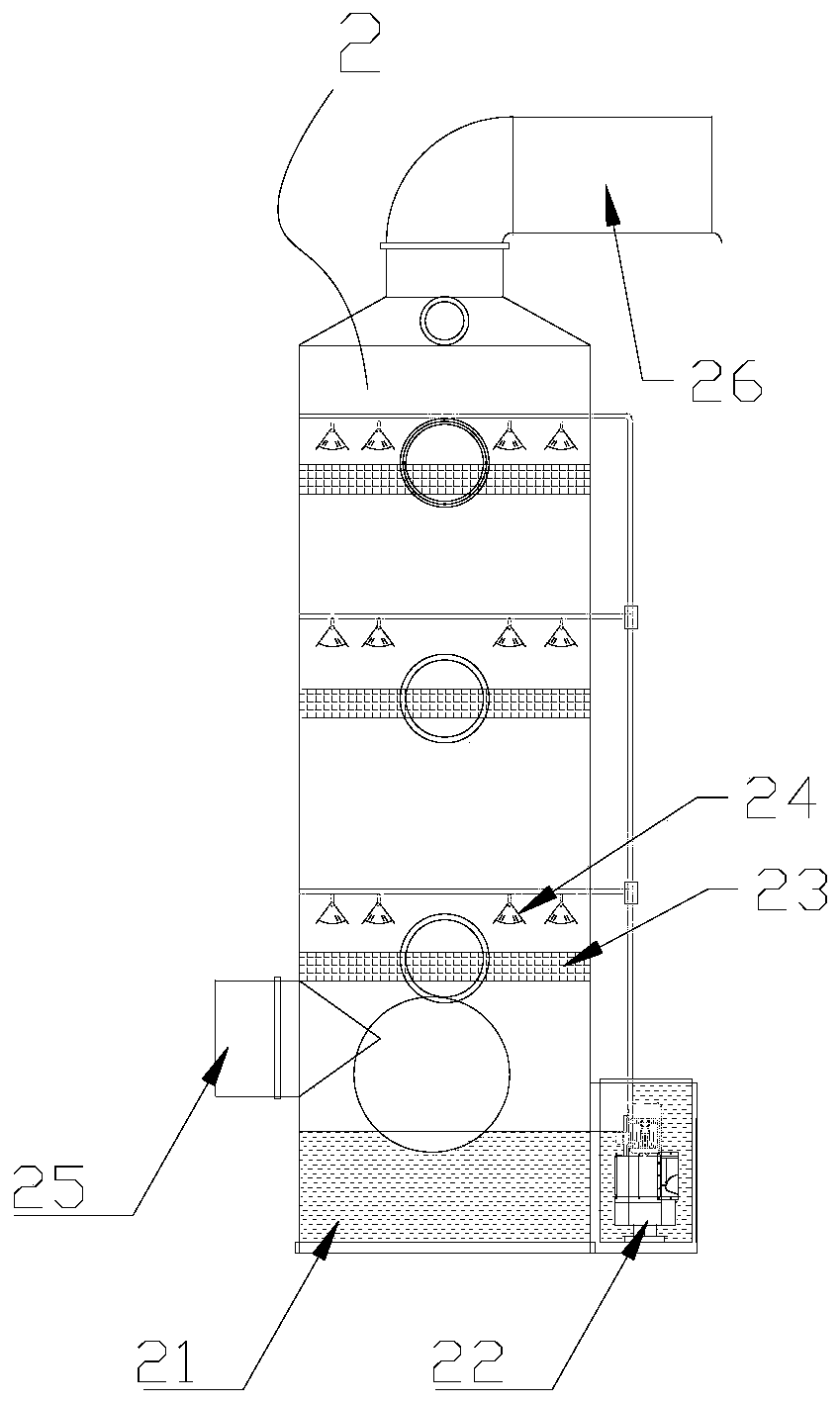

[0032] Absorption tower 2 part: including being arranged in washing liquid pool 21, multi-stage scrubbing laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com