Miniature high-torque high-speed joint integrated hydraulic driver

A hydraulic drive, high torque technology, applied in the field of robots, can solve the problems of low inertia, high load high frequency response, high power density, etc., and achieve the effect of improving power density ratio, increasing life, and reducing inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

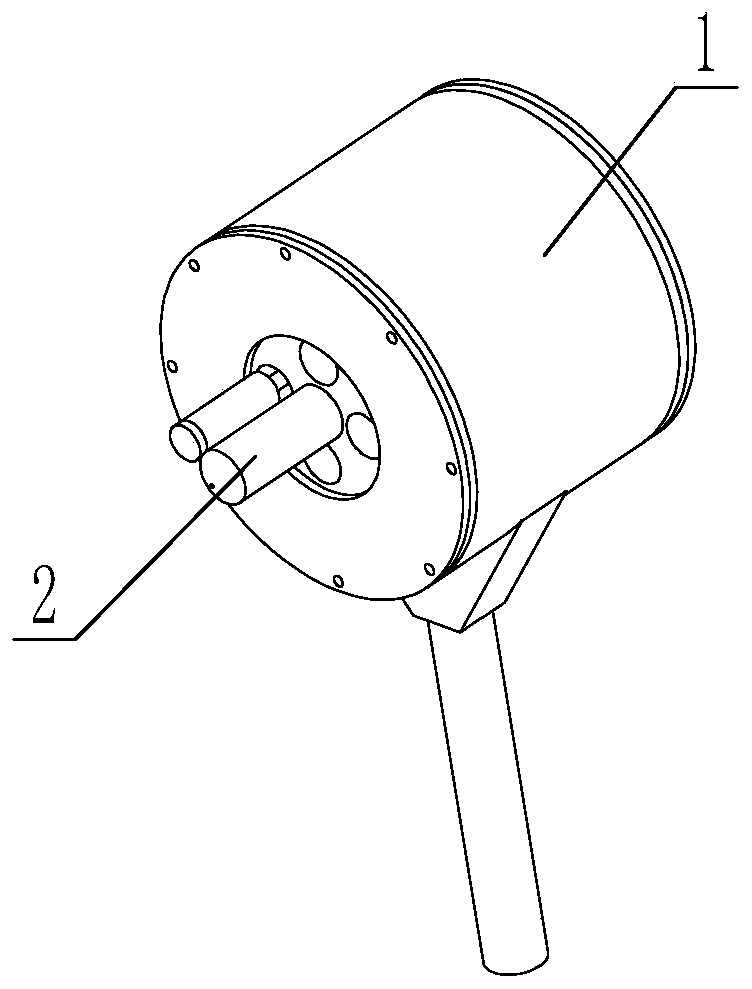

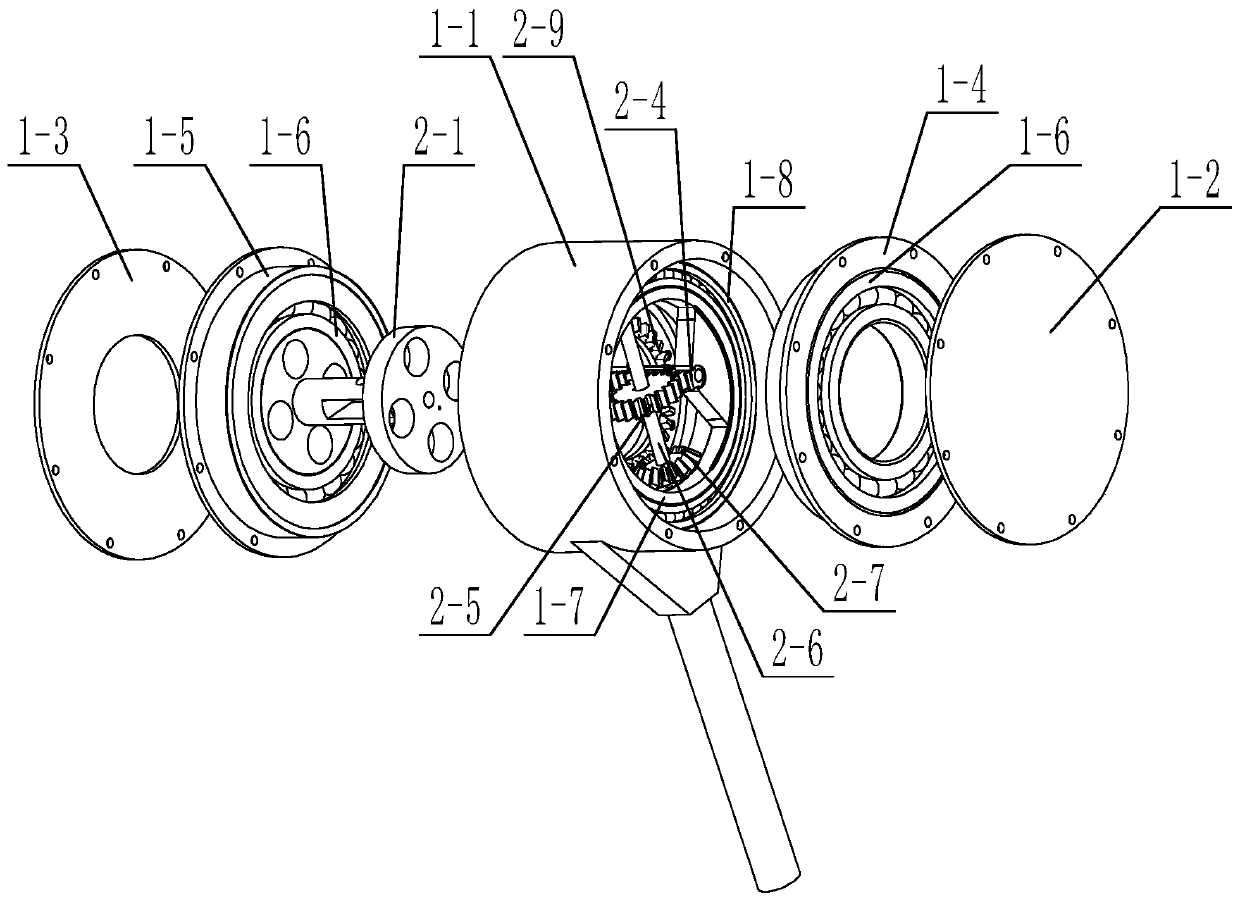

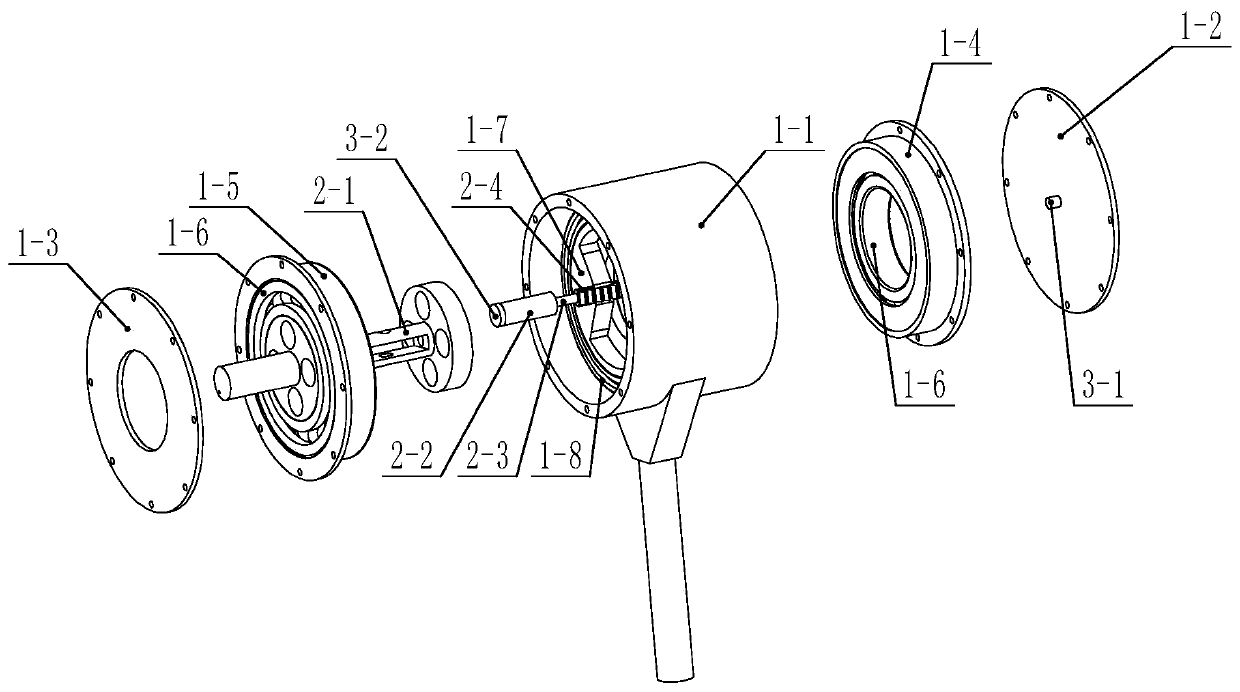

[0018] like Figure 1-4 As shown, a miniature high-torque high-speed joint integrated hydraulic driver includes a mechanical structure body 1, a transmission chain unit 2, a torque speed sensor 3-1, and a force and displacement sensor 3-2. The transmission chain unit 2 is located in the mechanical structure In the body 1, the mechanical structure body 1 includes an outer shell 1-1, a rear end cover 1-2, a front end cover 1-3, a rear support bearing sleeve cup 1-4, a front support bearing sleeve cup 1-5, two A support shaft bearing 1-6, two rack holders 1-7, two rack holder bearings 1-8, slip ring bearings 1-9, two support shaft bearings 1-6 are respectively assembled on the support shaft 2-1 Inside the rear support bearing sleeve cup 1-4 and the front support bearing sleeve cup 1-5 at both ends, the rear end cover 1-2 is attached to the end surface of the rear support bearing sleeve cup 1-4, and the front end cover 1-3 is pasted Closed on the end face of the front support bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com