Flexible wheel with U-shaped metal elastic supporting body

A technology of elastic support and support body, applied in the direction of highly elastic wheels, wheels, vehicle parts, etc., can solve the problems of heat dissipation, tire blowout, etc., and achieve the effects of good cushioning performance, low cost, and uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For ease of understanding, the technical solutions of the present invention are further specifically described below in conjunction with the accompanying drawings and through embodiments:

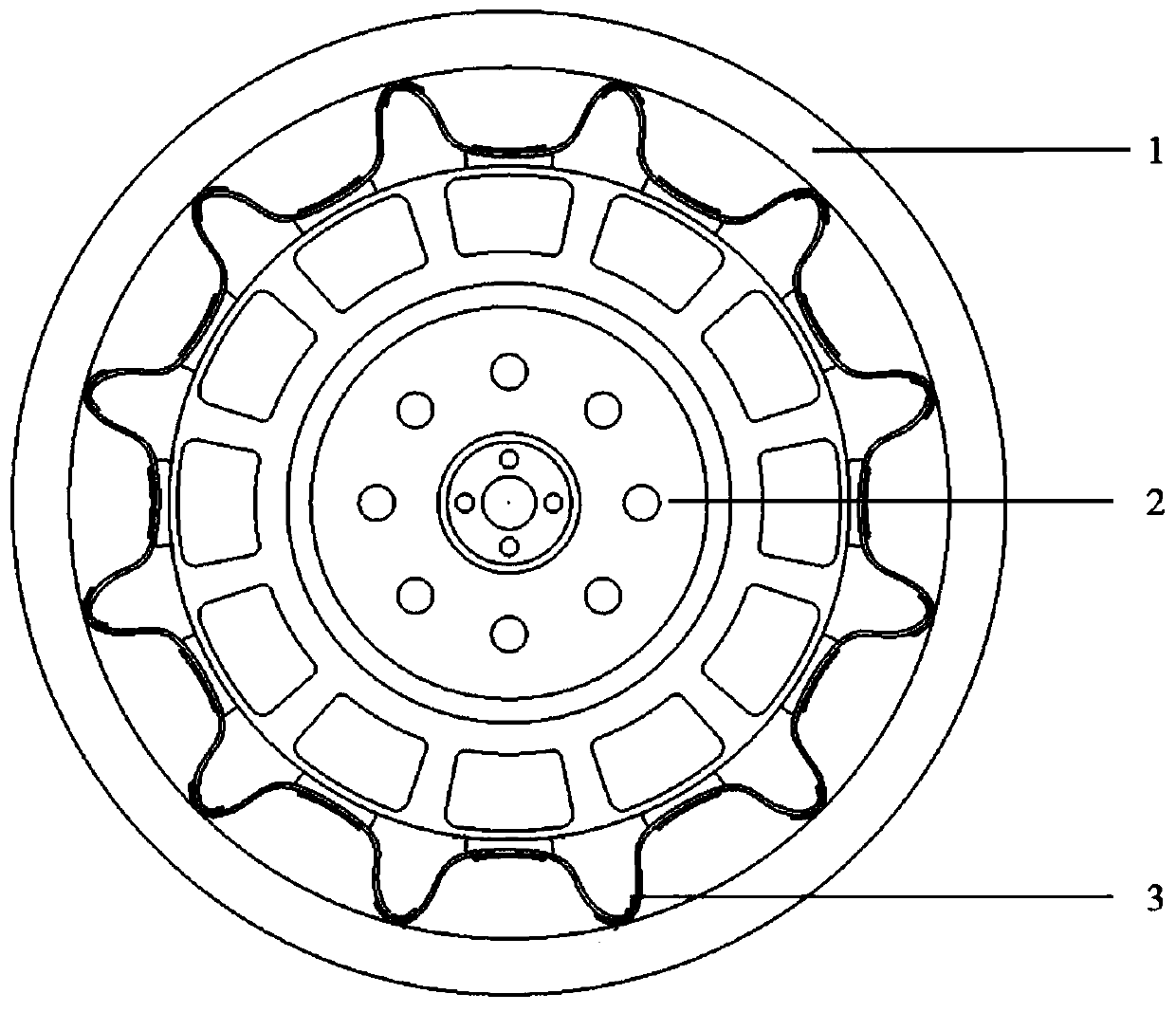

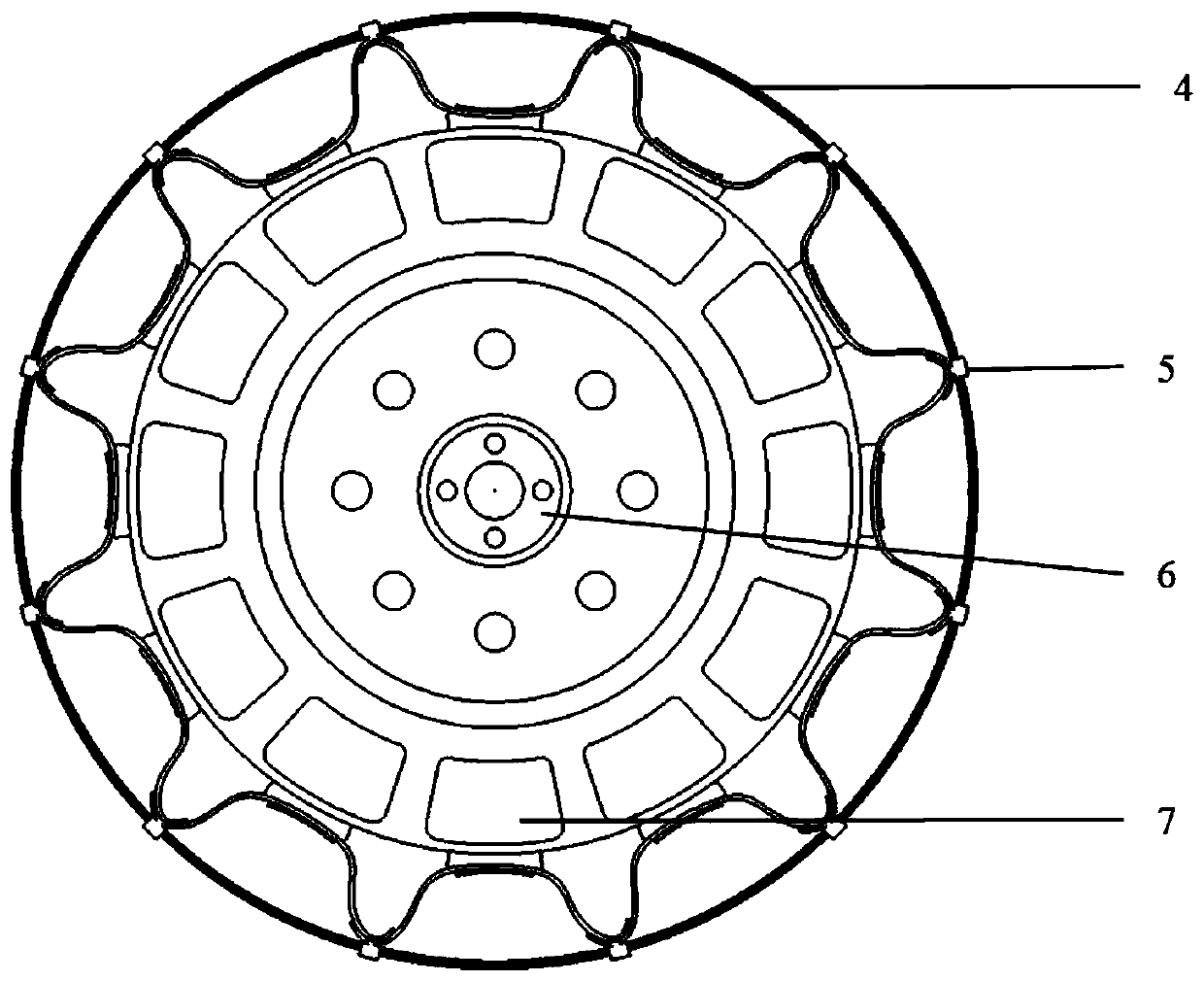

[0030] A flexible wheel with a U-shaped metal elastic support body, comprising an outer wheel module 1 , a central rim module 2 and a support body module 3 .

[0031] The central rim module 2 can be cast from metal materials such as steel or aluminum alloy according to performance requirements.

[0032] The hub 6 is arranged on the central rim module 2, and the hub 6 is connected with the half shaft of the vehicle.

[0033] Several weight-reducing rectangular holes 7 are arranged on the central rim module 2 .

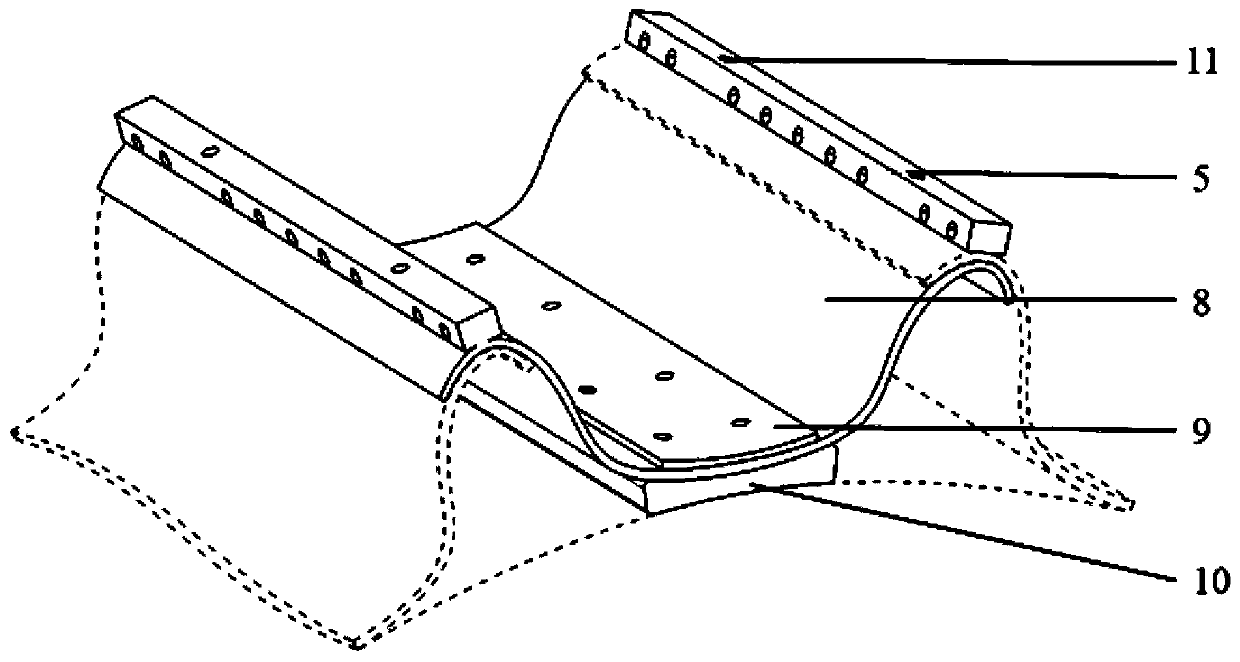

[0034] The support module 3 is composed of several U-shaped spoke plates 8 , outer fixing pieces 9 and inner fixing blocks 10 .

[0035] The inner surface of each inner fixing block 10 is connected with the outer surface of the central rim module 2 by spot welding. Several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com