Metal tube automatic iron wire binding machine

A metal tube and strapping machine technology, which is applied to the parts of strapping machines, strapping objects, and strapping materials, etc., can solve the problems of high machine price, low tightness of metal threading tubes, and easy slipping of tubes, etc., to reduce worker labor Strength, strong and reliable binding, labor cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

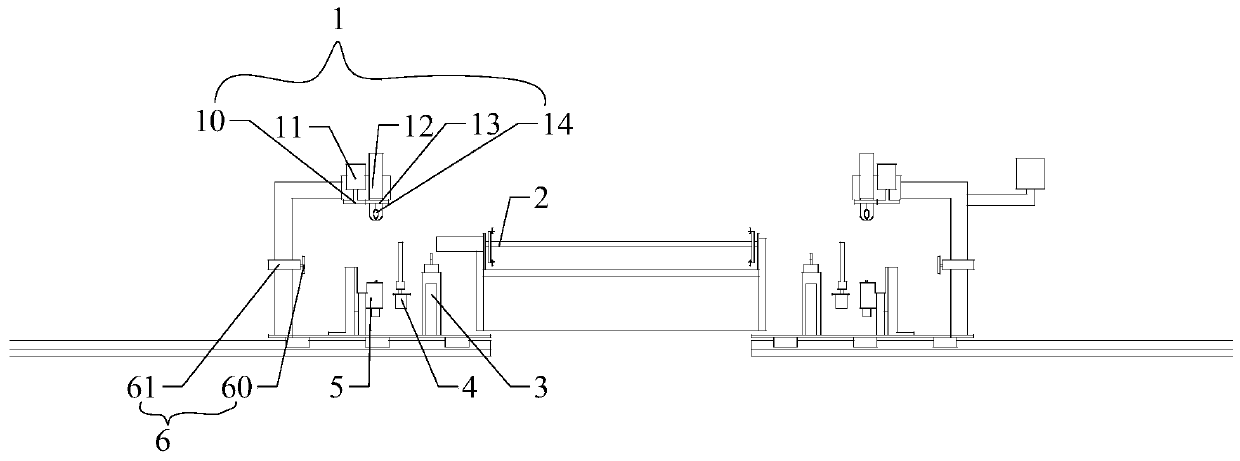

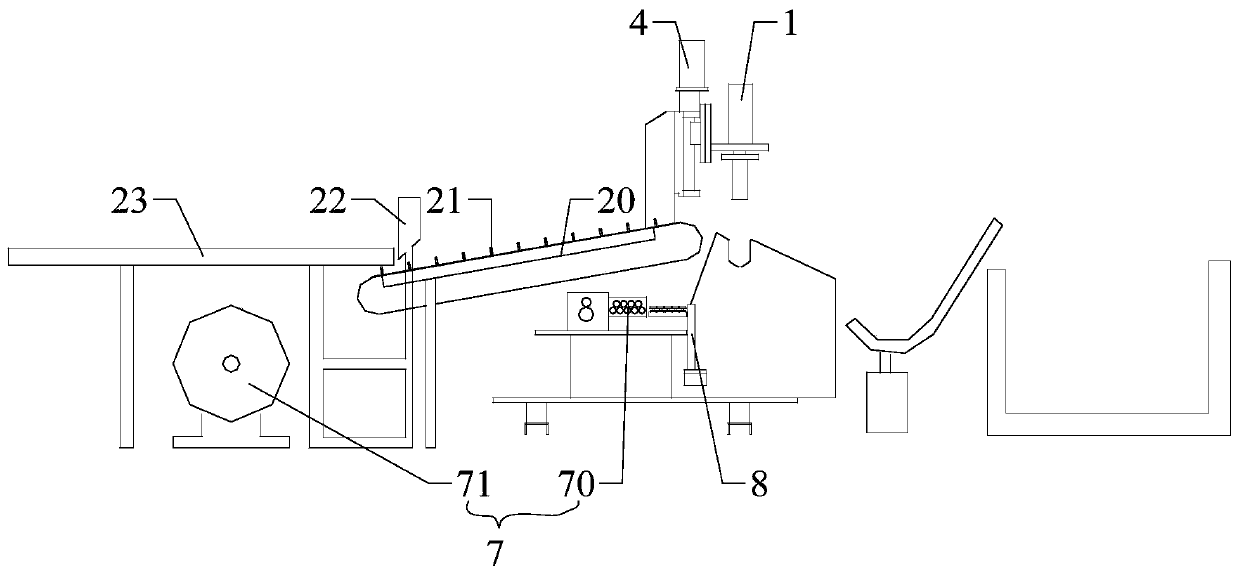

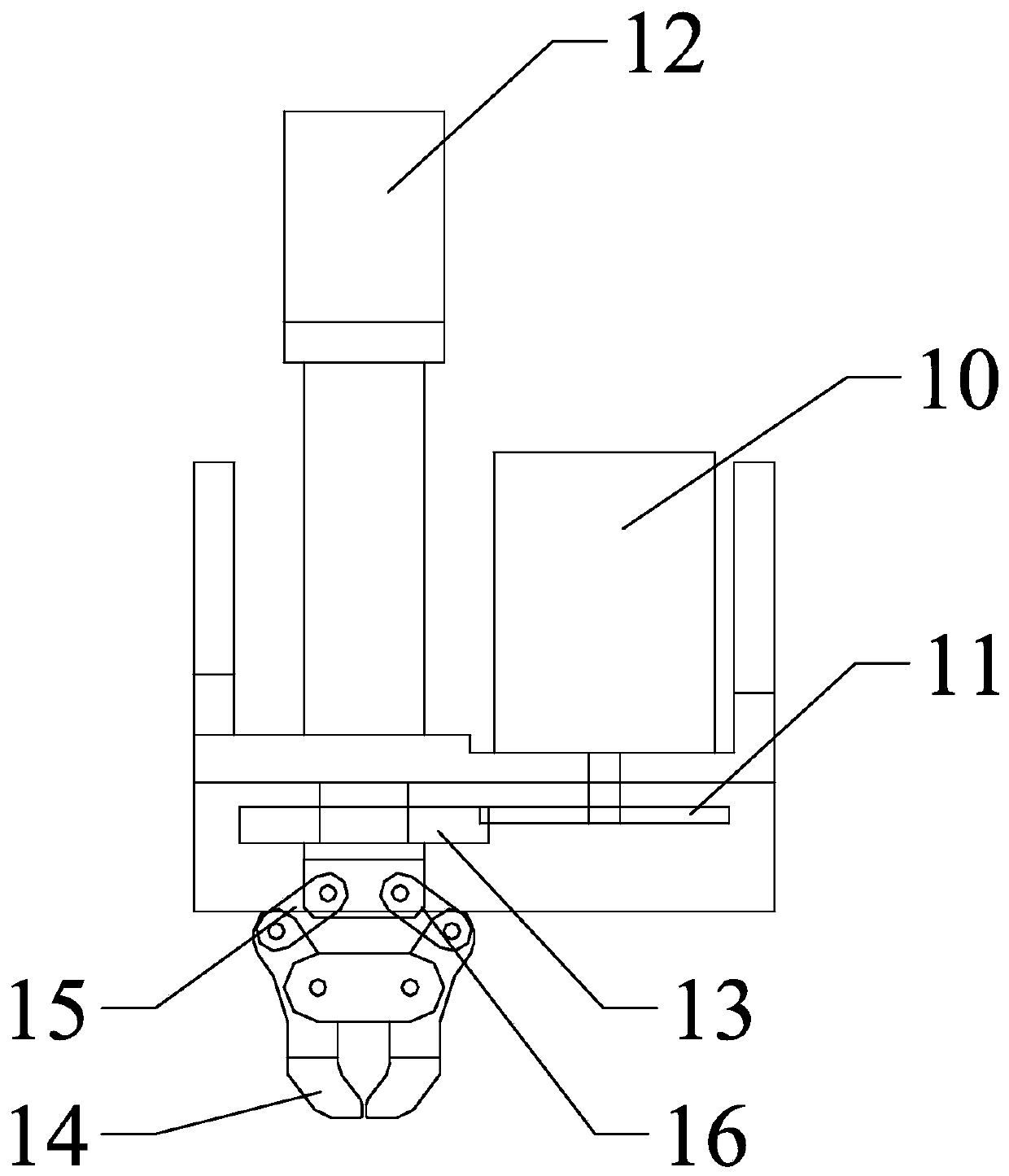

[0032] figure 1 It is the front view of a metal tube automatic wire binding machine according to the embodiment of the present invention, figure 2 It is a side view of a metal pipe automatic wire binding machine according to an embodiment of the present invention, image 3 It is a schematic structural diagram of a wire twisting mechanism of an automatic iron wire binding machine for metal pipes according to an embodiment of the present invention, Figure 4 It is a schematic structural diagram of the unloading mechanism of a metal tube automatic wire binding machine according to an embodiment of the present invention, Figure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap