Heat seal sealing machine and heat seal sealing method

A thermal sealing machine and heat sealing technology, applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of undiscovered thermal sealing machines, etc., to improve packaging operation efficiency and packaging quality, low manufacturing cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

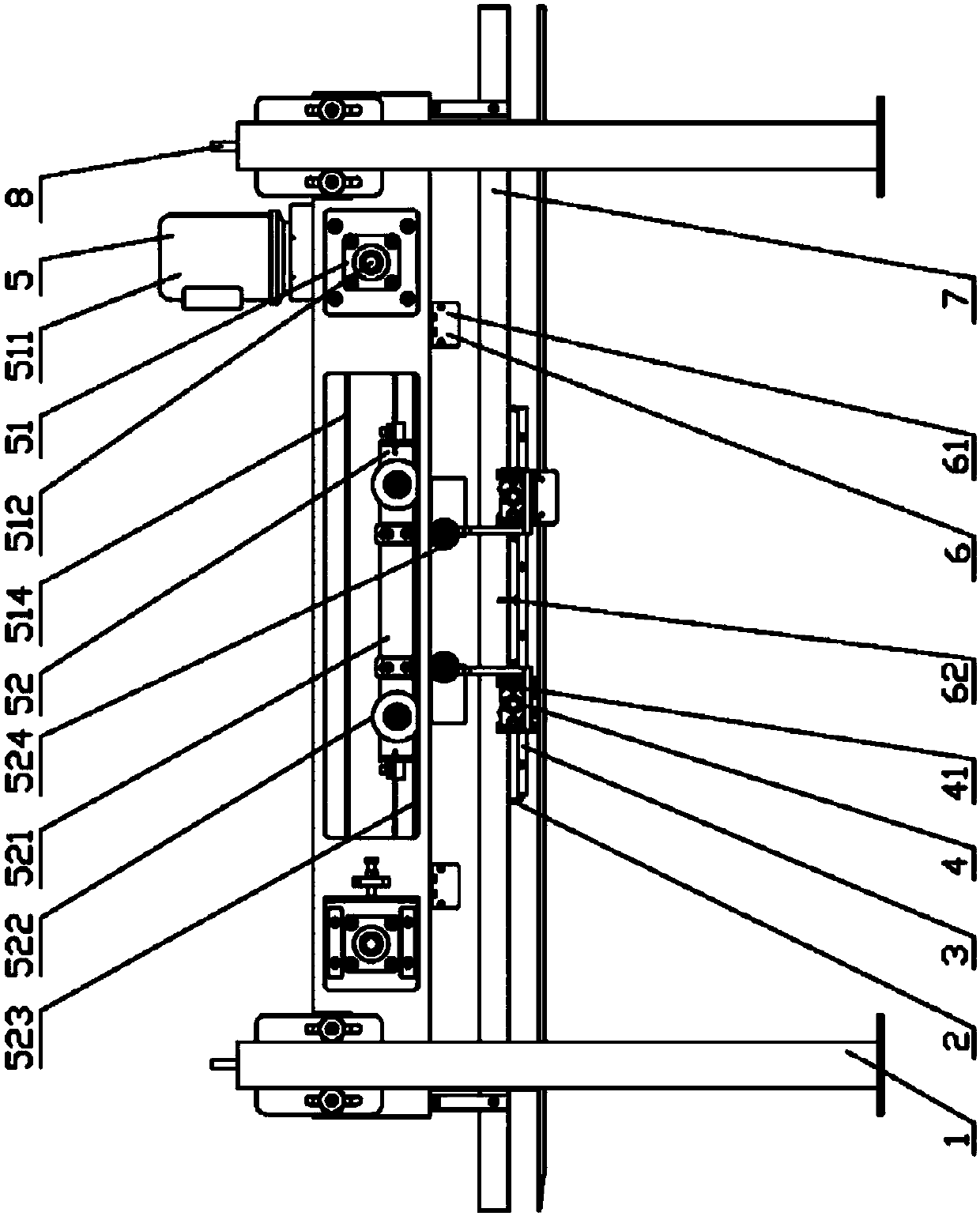

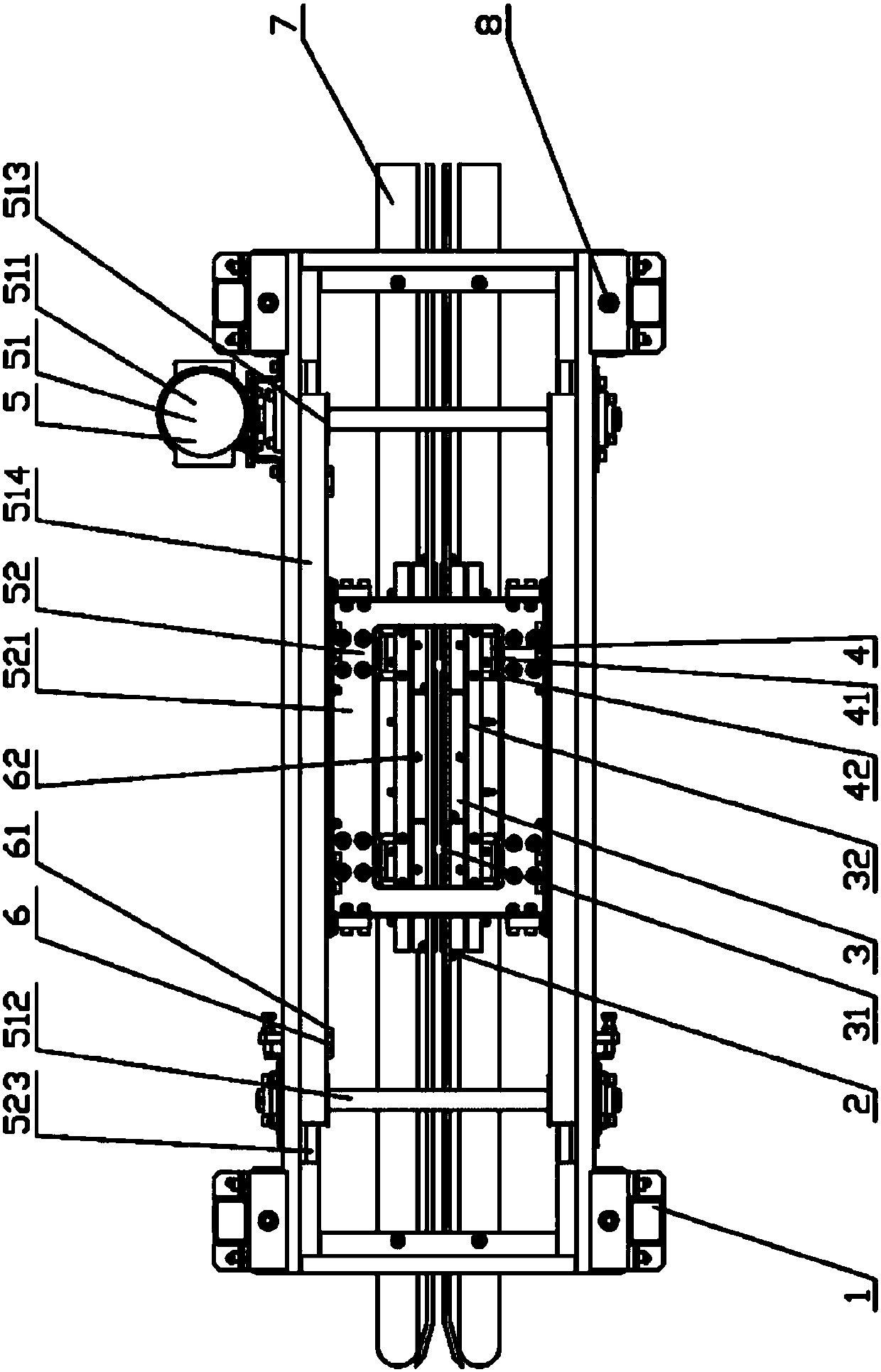

[0070] Such as figure 1 , figure 2 , image 3 As shown, the heat sealing machine of the present invention is mainly composed of a frame 1, a heating pipe 2, a heat sealing block 3, a heat sealing pushing device 4, a heat sealing moving device 5 and a sensor 6; On a plane, the heating tube 2 is installed in the heat-sealing block 3, the heat-sealing block 3 is fixedly connected to the front end of the heat-sealing pushing device 4, and the heat-sealing pushing device 4 is connected and installed in the The heat sealing moving device 5 is connected and installed on the frame 1 , and the sensor 6 is installed on the frame 1 above the heat sealing pressing device 4 .

[0071] Described heat-sealing pushing device 4 is made of pushing cylinder 41; Described pushing cylinder 41 has four, two on each side, opposite and dress, and the piston rod of pushing cylinder 41 is connected with heat-sealing block 3, in order to avoid Too much heat on the heat sealing block 3 is transferred...

Embodiment 2

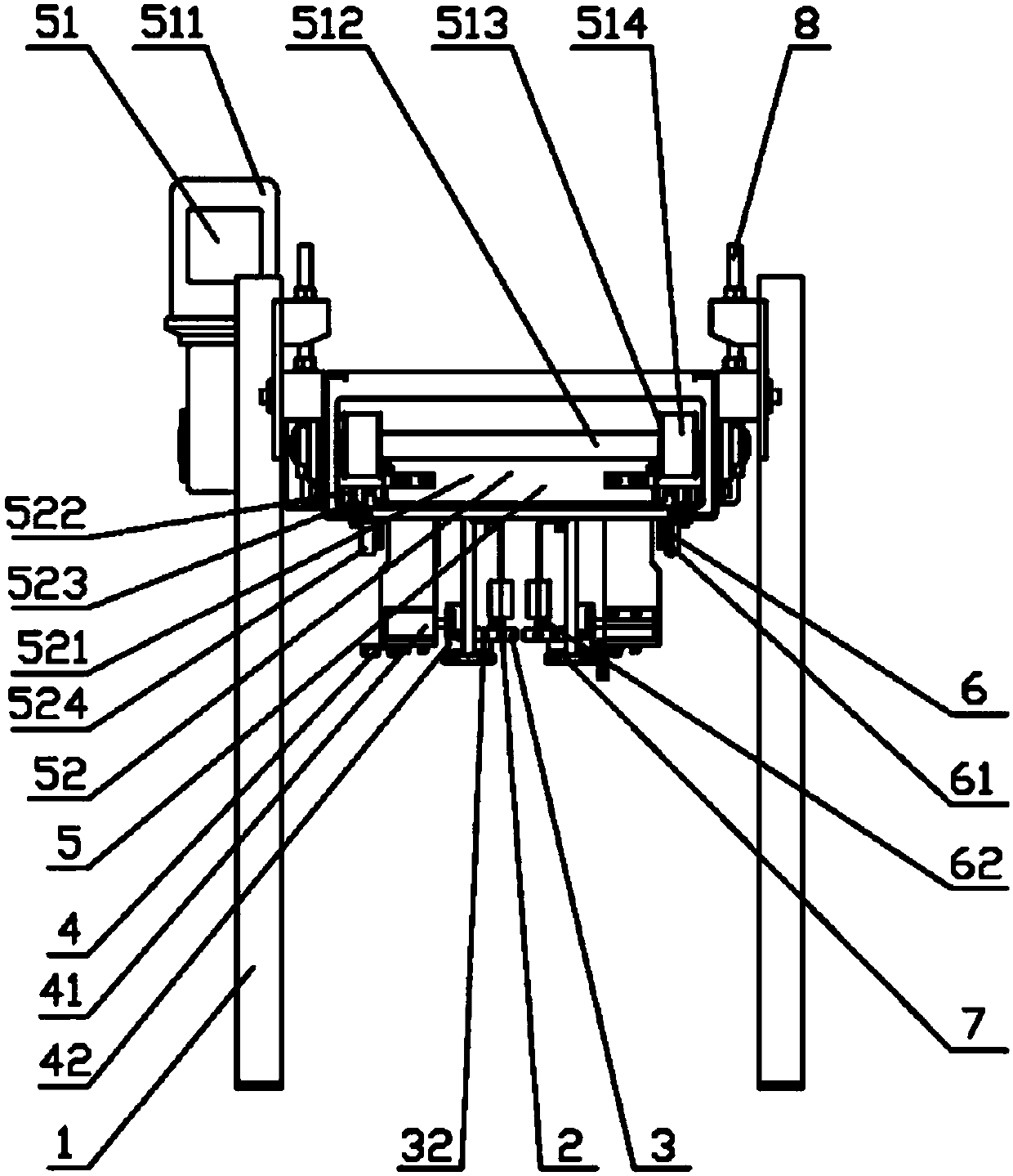

[0081] see Figure 4 , Figure 5 , Figure 6 As shown, the heat sealing machine of Embodiment 2 of the present invention is similar to Embodiment 1, the difference is only in:

[0082] The heat sealing pushing device 4 is composed of a pushing cylinder 41 and a guide limiting mechanism 43; there are two pushing cylinders 41, which are symmetrically installed opposite to each other, and the guiding limiting mechanism 43 is installed on both sides of the pushing cylinder , the piston rod of the pushing cylinder 41 and the guide and limit mechanism 43 are respectively connected with the heat sealing block 3 .

[0083] The heat sealing moving device 5 is arranged below the heat sealing pushing device 4; the transmission synchronous wheel 513 and the transmission synchronous belt 514 of the driving mechanism 51 of the heat sealing mobile device 5 are respectively replaced by a transmission sprocket 515 and a transmission Chain 516.

[0084] The heat sealing lifting mechanism 8 ...

Embodiment 3

[0086] see Figure 7 As shown, the heat sealing machine of the third embodiment of the present invention is similar to the first embodiment, the only difference is:

[0087] In order to form an automated production system with more complete functions and higher efficiency and realize large-scale assembly line operations, the heat sealing machine is also connected with a packaging conveyor 9 and a packaging bag mouth shaping machine 10; The machine 9 is arranged below the heat-sealing block 3 and the heat-sealing pushing device 4; the packaging bag opening shaping machine 10 is installed in series at the front end of the heat-sealing sealing machine.

[0088] In order to meet the packaging sealing of some products with higher packaging requirements, sewing sealing is also performed while heat sealing is performed, and a packaging bag sewing sealing machine 11 is installed in series at the rear end of the heat sealing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com